Feed spreader

A technology of a spreader and feed is applied in the field of feed spreader, which can solve the problems of troublesome unloading process, low level of mechanization, low efficiency, etc., and achieve the effects of simple structure, improved efficiency and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

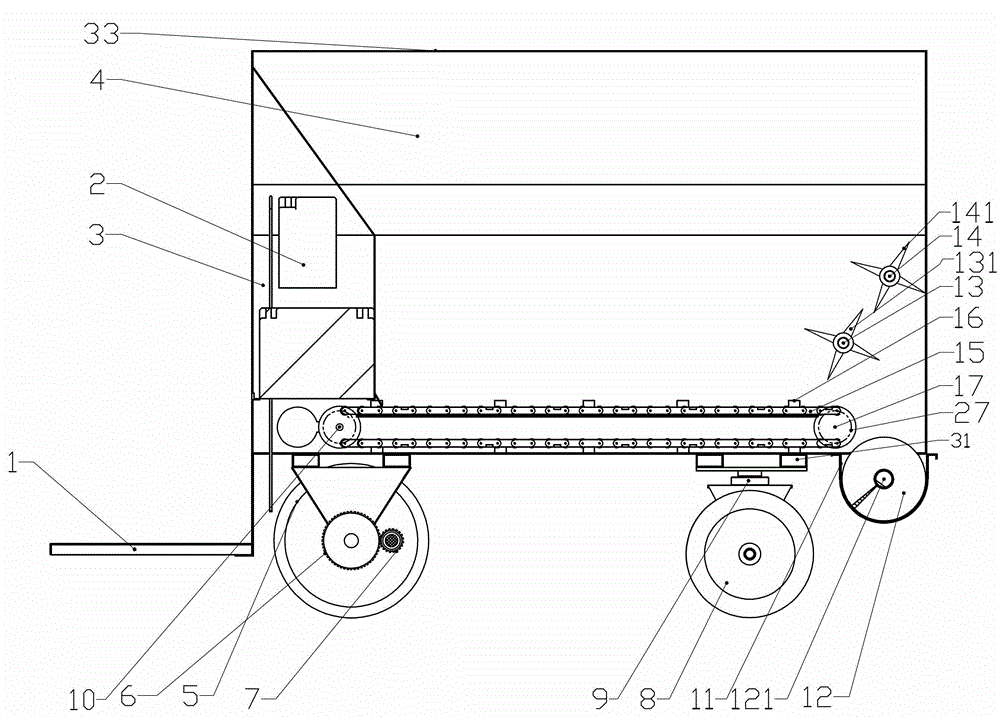

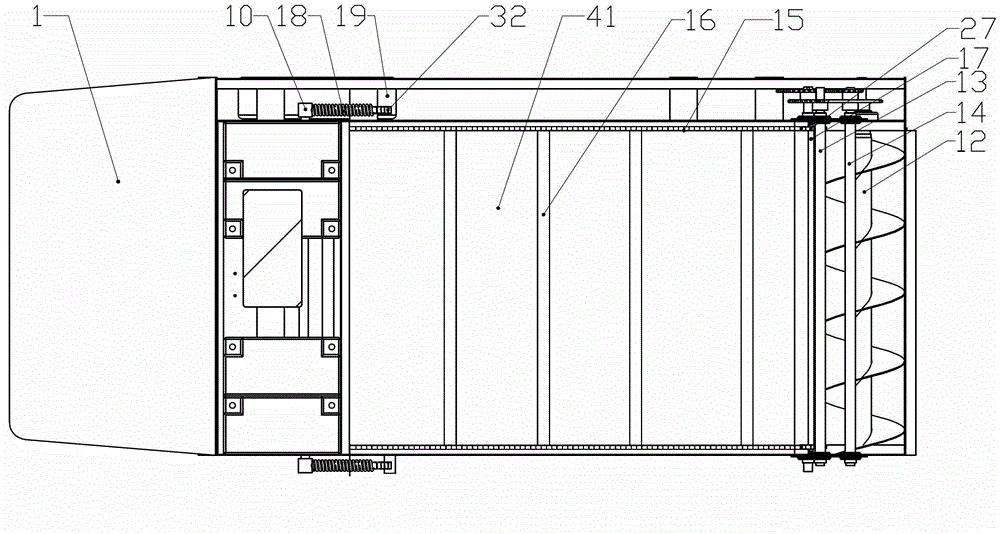

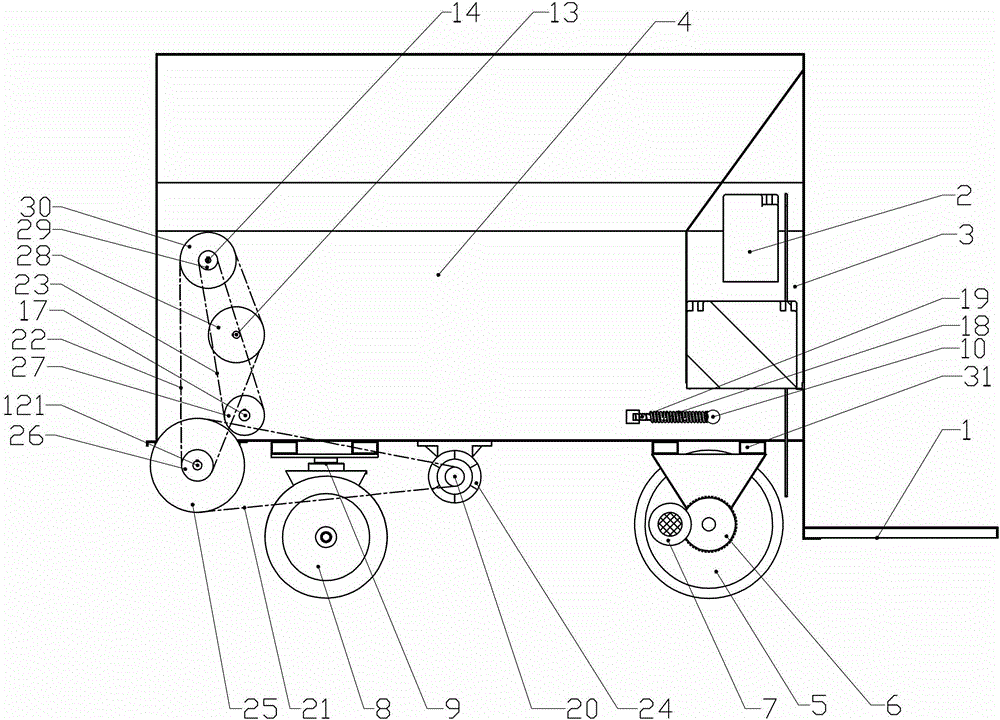

[0022] as attached figure 1 , figure 2 , image 3 shown.

[0023] A feed spreader includes a car body 33, a power drive mechanism and a running mechanism, and the power drive mechanism drives the car body through the running mechanism. The spreading mechanism is the main part of the feed spreading machine.

[0024] The distributing mechanism includes a horizontal bottom plate 41 located at the bottom of the car body material compartment 4. There are gaps between the front and rear ends of the bottom plate 41 and the car body. On both sides of the car body, on both sides of the scraper driving shaft 17 and the scraper driven shaft 10, two chains 15 arranged in parallel longitudinally are connected by the sixth gear 27, and the sixth gear 27 cooperates with the chain 15. A plurality of strip scrapers 16 are connected between the two chains 15 , the upper part of the chains 15 is provided on the bottom plate 41 , and the lower part of the chains 15 is provided under the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com