A coil clamp

A technology of coils and fixtures, applied in the field of water-cooled heat exchange tubes, to achieve the effect of eliminating dead spots and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

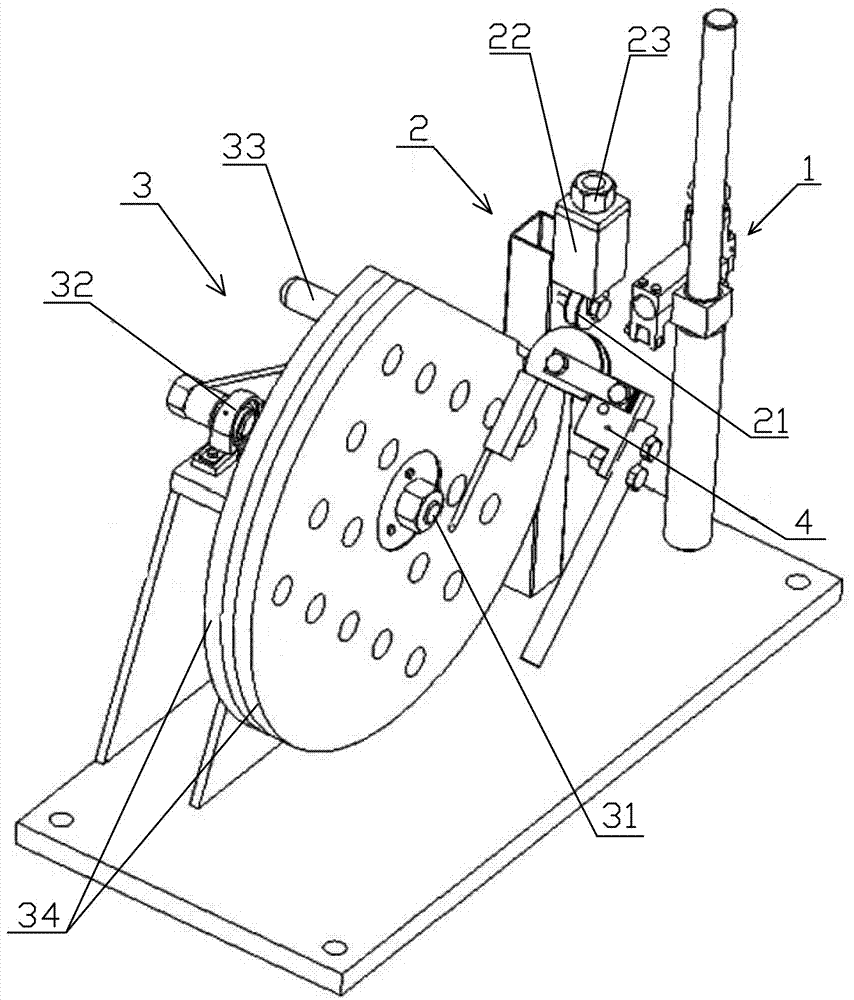

[0020] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

[0021] The operation steps are as follows:

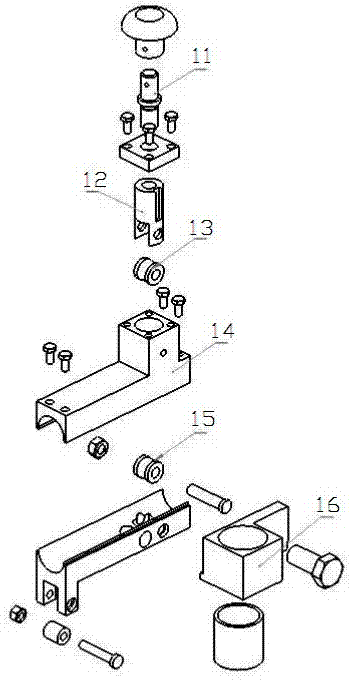

[0022] First, install the fixed pulley guide device 2 on the base plate through the bracket, adjust the first bolt 23 to make the fixed pulley 21 at an appropriate height and fix it with a lock nut.

[0023] Then, pass the stainless steel spiral pipe or straight pipe first through the fixed pulley guide device 2, adjust the first bolt 23 to cooperate with the fixed pulley 21 to compress the stainless steel spiral pipe or straight pipe, so that it passes through the fixed pulley guide device 2, and then use the manual pipe bender 4 Fix one end of the stainless steel spiral tube or straight tube, turn the handle to drive the disc wheel 34, the disc wheel 34 makes the stainless steel spiral tube or straight tube slowly enter the coil device 3, rotate the coil device 3 through the rotating shaft, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com