Drawn-arc stud welding gun driven by linear motor and welding method of welding gun

A linear motor and stud welding technology, which is applied to arc welding equipment, welding equipment, electrode characteristics, etc., can solve the problems of inability to adjust the discharge amount and arc distance, and achieve the effects of compact structure, low cost, and increased welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

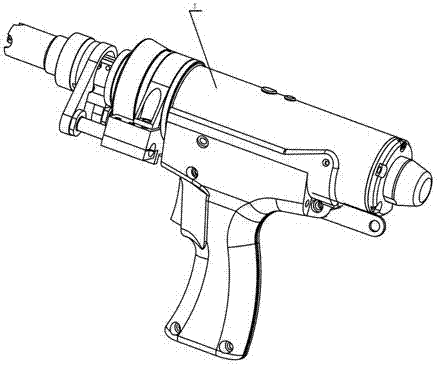

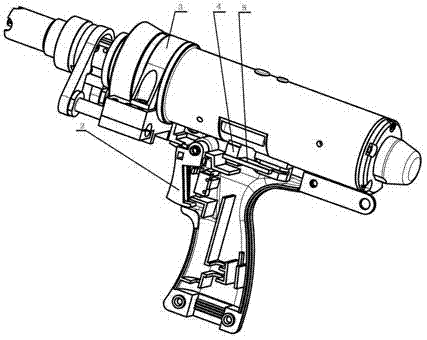

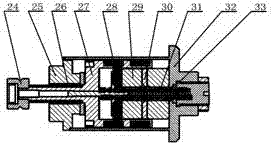

[0027] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment: as figure 1 , figure 2 , image 3 ,and Figure 4 As shown, a linear motor-driven drawn arc stud welding torch includes a fixed assembly, a movable assembly, a linear motor, a grating for sensing distance, and a grating receiver; wherein, the fixed assembly includes a welding button (2), a gas seat (4), body assembly, and anti-splash assembly; the grating (5) and the grating receiver (22) of the sensing distance are fixed on the air socket (4), and are used to transmit the distance signal to the controller of the linear motor , to achieve induction control of the arc distance.

[0028] The body assembly includes a gun barrel (18), a locking ring (3) for fixing the gun barrel, a handle (23), and an insulating inner sleeve (13);

[0029] The movable assembly is installed in the inner cavity of the fixed assembly and is supported by the fixed assembly; the movable as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com