Processing working table of guide vane shaft hole of inner and outer water distribution rings of turbine

A water distribution ring and guide vane shaft technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inaccurate positioning, coaxiality of inner and outer ring holes not meeting the requirements, and low processing efficiency. Achieve the effect of firm structure, good economic benefits and avoiding multiple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

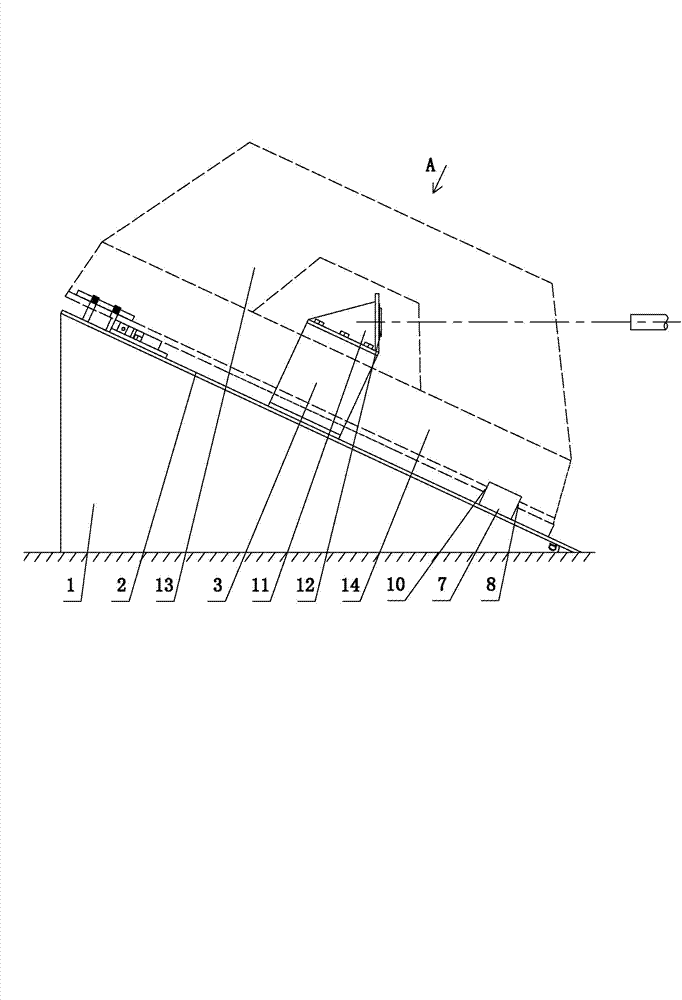

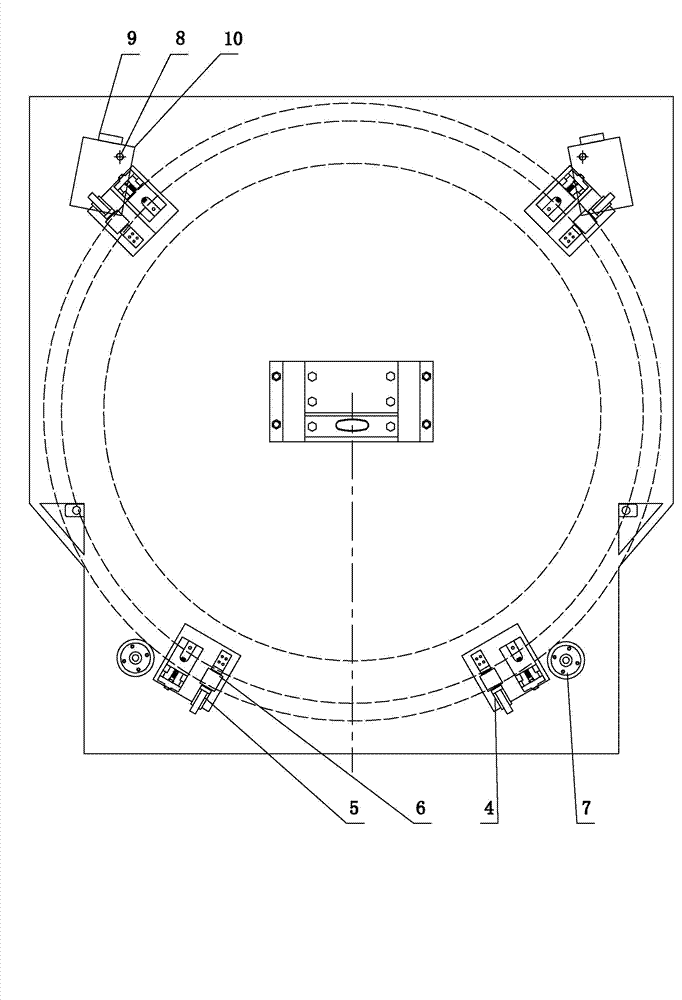

[0012] figure 1 It is a structural schematic diagram of the present invention, figure 2 yes figure 1 Middle A view. As shown in the figure, the workbench for processing the guide vane shaft holes of the inner and outer water distribution rings of the water turbine includes a base 1, a tooling surface 2 is arranged above the base 1, and an inclination angle α=25° is set between the tooling surface 2 and the base 1. The center of the tooling surface 2 is provided with a support seat 3 perpendicular to the tooling surface 2, and a plurality of roller brackets 4 are arranged on the periphery of the tooling surface 2. The roller bracket 4 is provided with an eccentric roller shaft 5, and the eccentric roller shaft 5 is sleeved There are workpiece support rollers 6; side positioning wheels 7 are arranged around the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com