Grinder dust cover

A technology of dust collection hood and grinder, which is applied in the field of machinery, can solve the problems that the dust collection hood and the grinder cannot be matched, the dust collection hood is prone to abnormal noise, and the shape of the dust collection hood is affected, so as to avoid repeated overall disassembly Easy to install, simple in structure and reasonable in design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

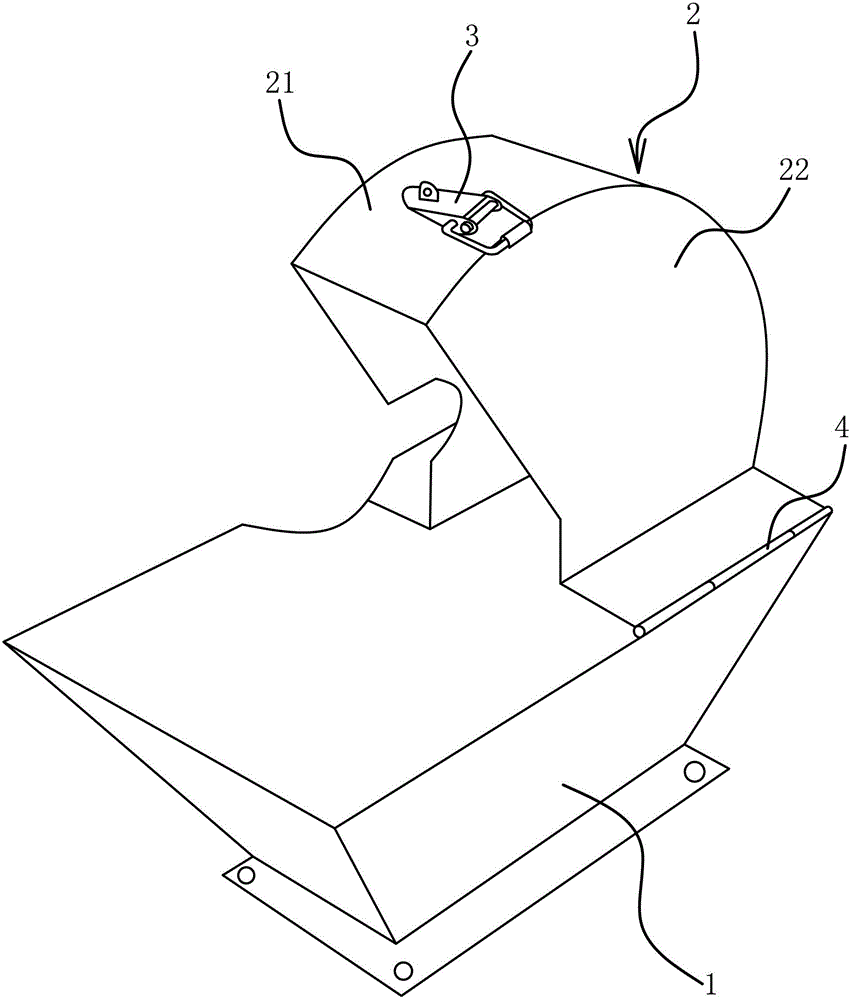

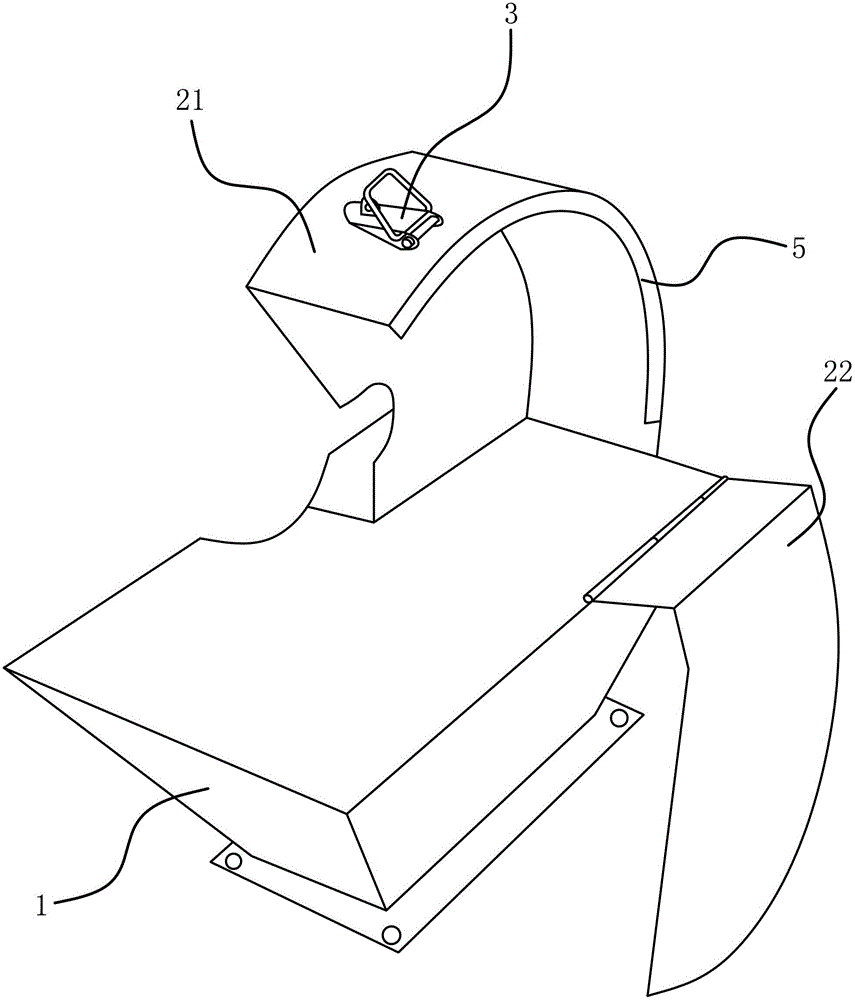

[0023] Such as figure 1 , figure 2 The grinder dust collection hood shown includes a base body 1 and a cover body assembly 2, wherein the cover body assembly 2 includes a fixed cover plate 21 and a connecting portion, and the movable cover plate 22 is connected to the base body 1 and / or the cover body. The fixed cover panels 21 of the body assembly 2 are connected through a locking structure that can separate the movable cover panel 22 from the fixed cover panel 21 .

[0024] The base body 1 is covered at the bottom of the grinding wheel. The inner cavity of the base body 1 is bucket-shaped, and its large opening is located above the small opening. The base body 1 is provided with a relief groove 2 provided for the rotating shaft of the power supply. The cover body assembly 2 covers the top and rear side of the grinding wheel and is located at the top rear side of the base 1 . The fixed cover plate 21 is fixedly connected with the base body 1, and the fixed cover plate 21 i...

Embodiment 2

[0028] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that the locking structure includes a backing plate, the backing plate is located inside the movable cover plate and is fixedly connected to the fixed cover plate, and the backing plate can be connected with the movable cover plate The edges are abutted, and can be connected by bolts and nuts after abutting.

[0029] In this embodiment, the movable cover plate is simply connected to the fixed cover plate, and there is no connection between the movable cover plate and the base body through relevant connecting pieces, so that when the grinding wheel needs to be replaced, the bolts and nuts are unloaded, and the movable cover plate can be taken away. Next, disengage the entire dust hood. The advantage of this is that the movable cover plate will affect the disassembly and assembly of the grinding wheel.

Embodiment 3

[0031] The structural principle of this embodiment is basically the same as that of Embodiment 1, except that the locking structure includes a hinge and a bead, and the movable cover plate is hinged to the base through the hinge; one end of the bead is hinged to the base through a bolt and nut, The other end can rely on the outer surface of the movable cover plate.

[0032]After the movable cover plate is combined with the fixed cover plate, swing the bead to make the other end of the bead lean against the outer surface of the movable cover plate, and then tighten the bolts and nuts to make the bead and the substrate fixedly connected. When the movable cover plate needs to be separated from the fixed cover plate, the bolts and nuts are first unscrewed, then the bead is swung to separate the other end of the bead from the movable cover plate, and finally the movable cover plate is swung to make the movable cover plate rotate around the hinge. The locking structure is simple in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com