Large-width laser internal carving machine

A laser engraving and large-format technology, applied in decorative art, processing models, etc., can solve the problems affecting the effect of laser engraving, and achieve the effect of saving laser engraving cost, improving effect, convenient and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

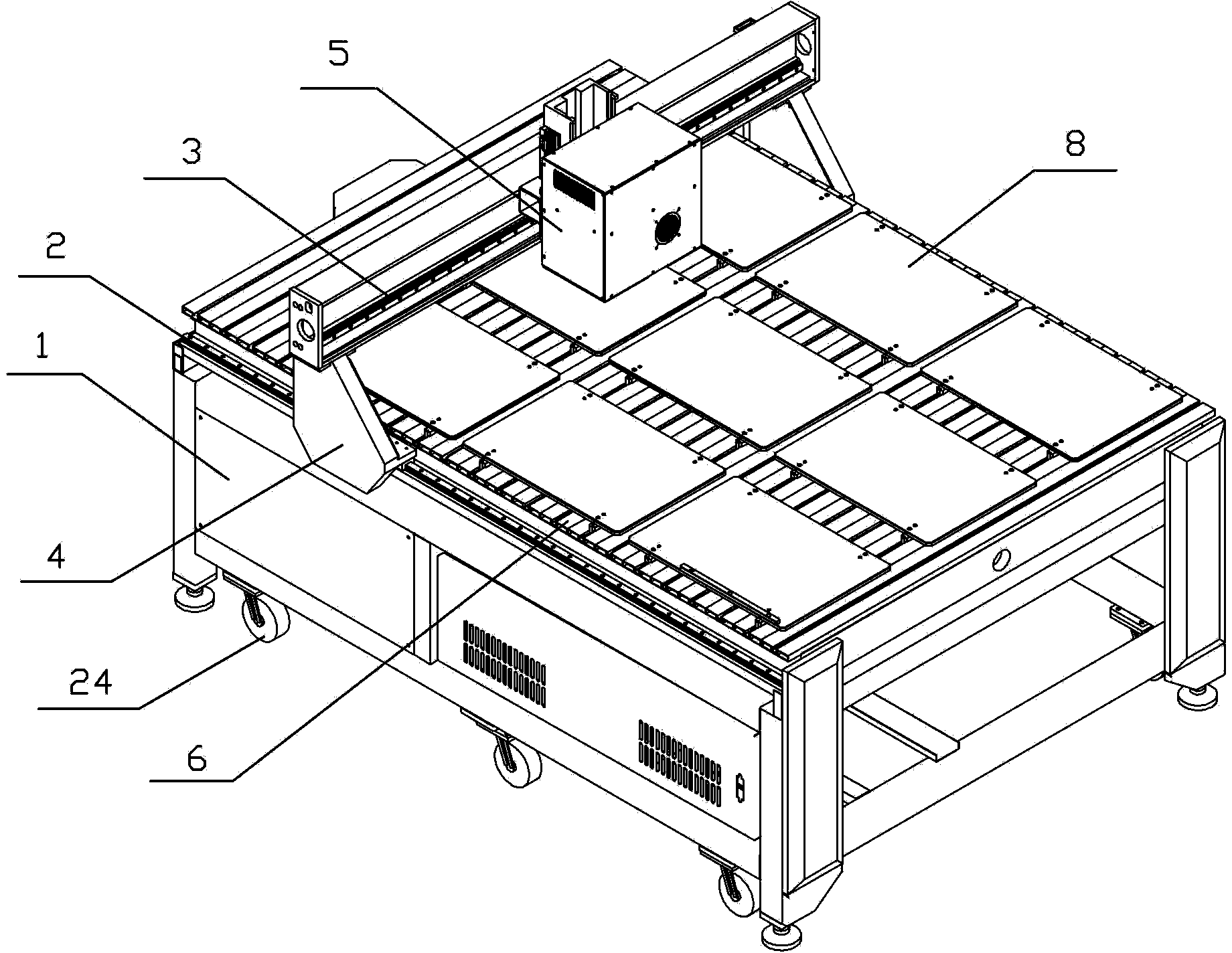

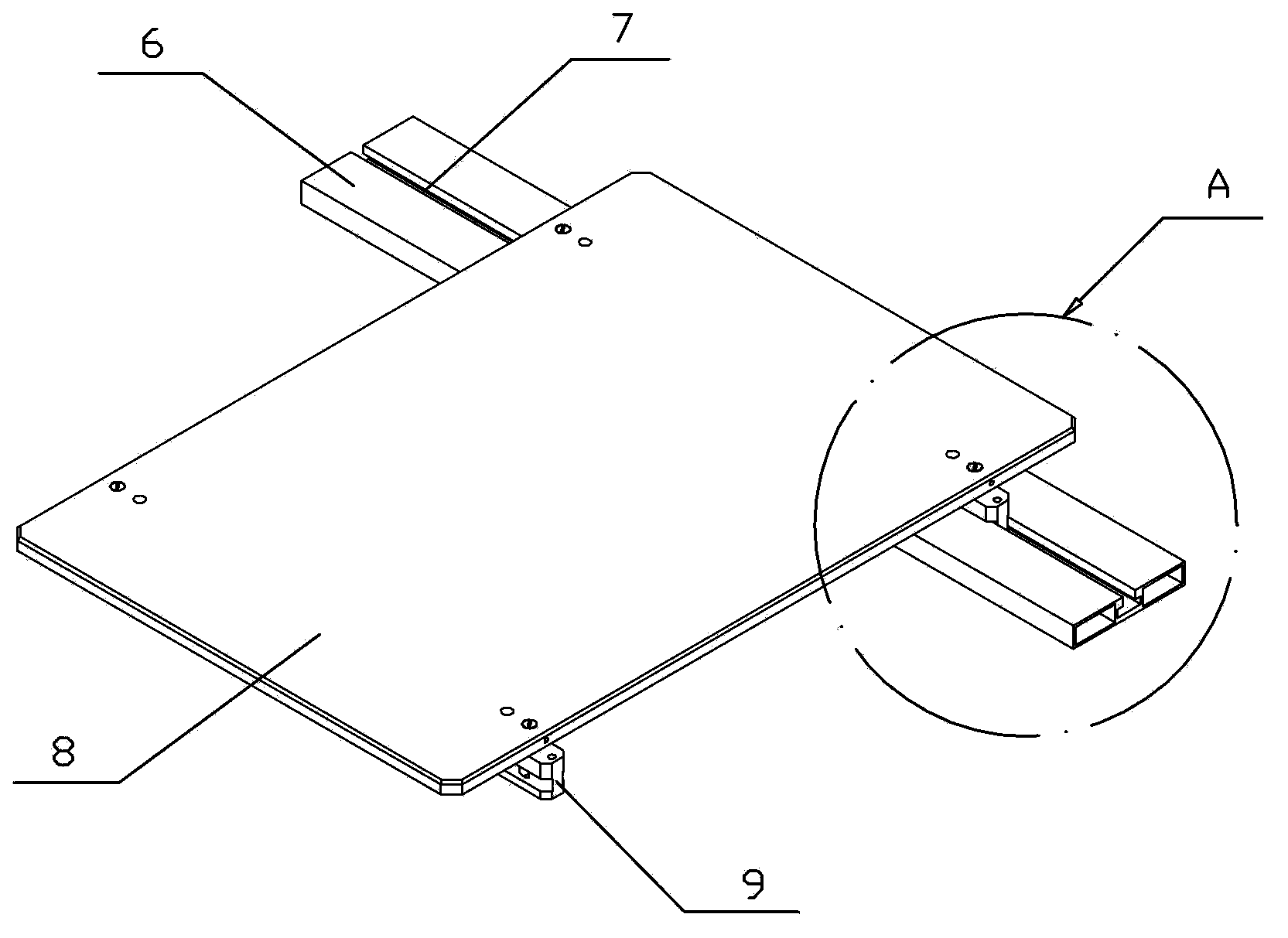

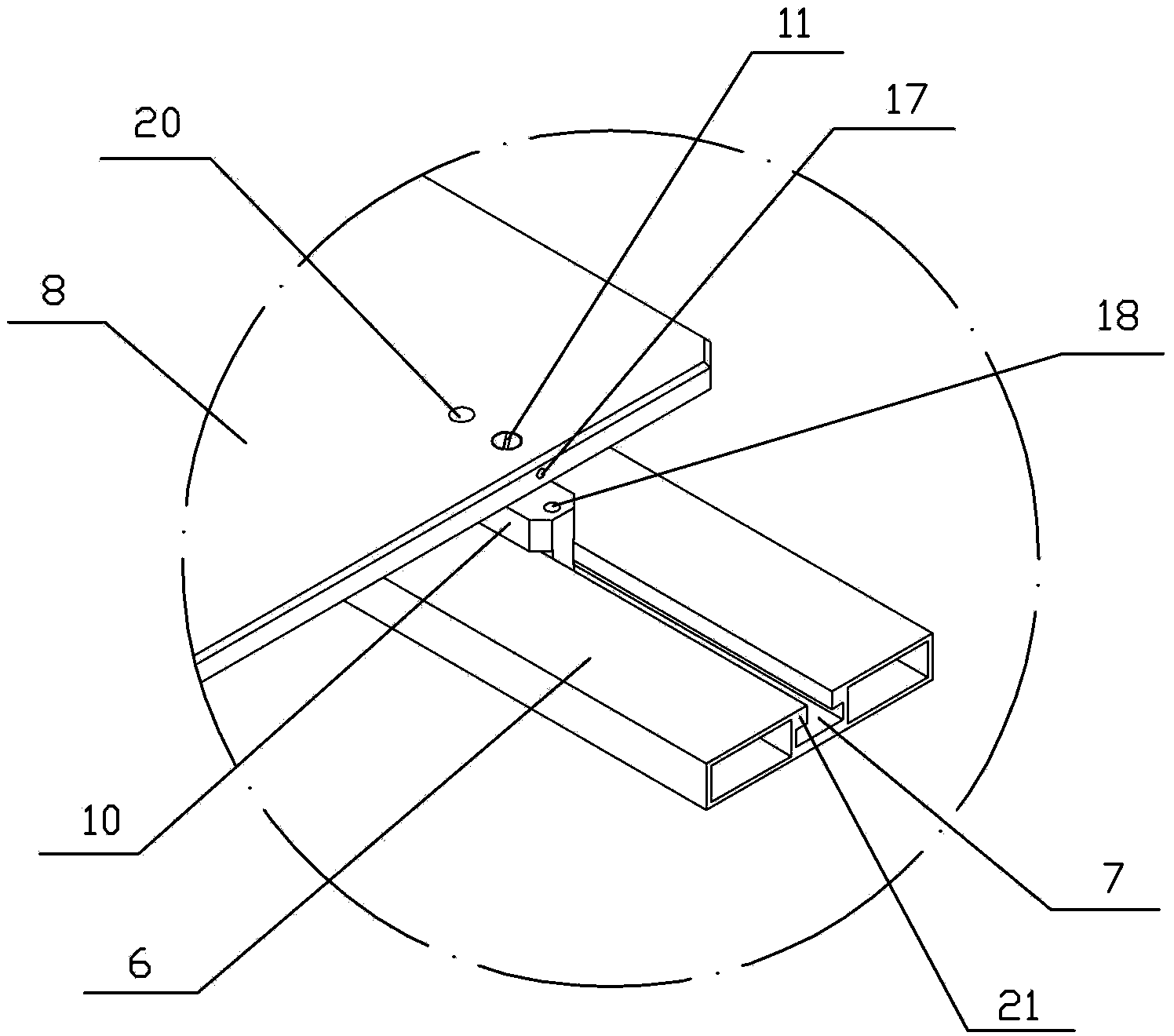

[0023] Embodiment: the large-format laser engraving machine of the present embodiment, such as figure 1 As shown, it includes a bed 1 composed of bed feet and a bed board connected between the bed feet, and a Y-axis track 2 and an X-axis track 3 installed on the bed 1. The bed is supported by four adjustable bed feet, and the bed board There is a distance from the bottom edge of the bed board to the ground, and three wheels 24 are respectively installed at the bottom edge of the bed boards on the left and right sides, and the three wheels 24 are arranged at intervals and evenly distributed. There are two Y-axis rails 2, each located on the left and right sides of the bed 1, the X-axis rail 3 is suspended on the bed 1, and the two ends of the X-axis rail 3 are respectively connected with Y-axis rails that can be on the left and right sides 2, a support 4 sliding on the X-axis track 3, a laser processing head 5 that can move along the X-axis track 3 is installed, and a dial indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com