Polyurethane foam capable of being poured at room temperature

A polyurethane foam and conditioning technology, applied in the field of polyurethane foam, can solve the problems of inconvenient construction and difficulty in accurately controlling material temperature according to process requirements, so as to avoid inconvenience, improve construction processability, and meet the effects of low temperature insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

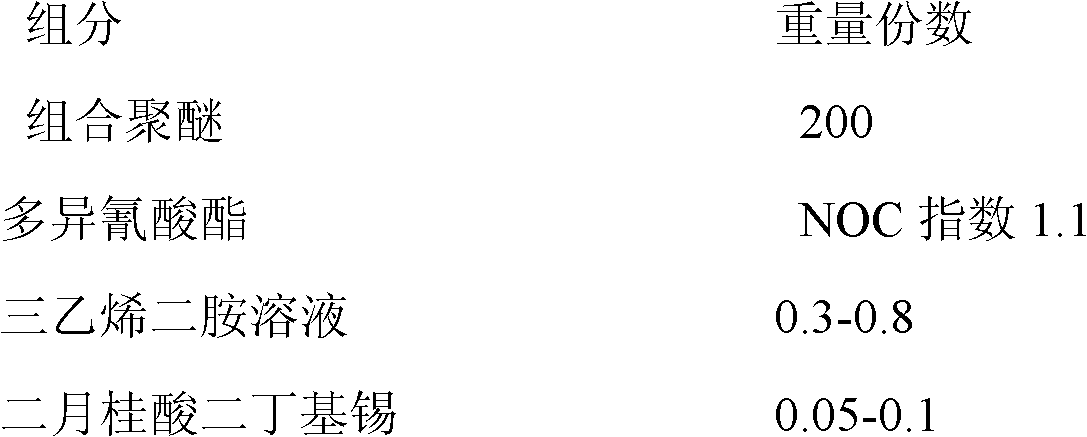

[0014] Composition of the invention

[0015]

[0016] Mix the prepared materials according to the above ratio, stir evenly and pour into the self-made mold for foaming. After the foam plastic is set, place it for a specified time before demoulding.

Embodiment 2

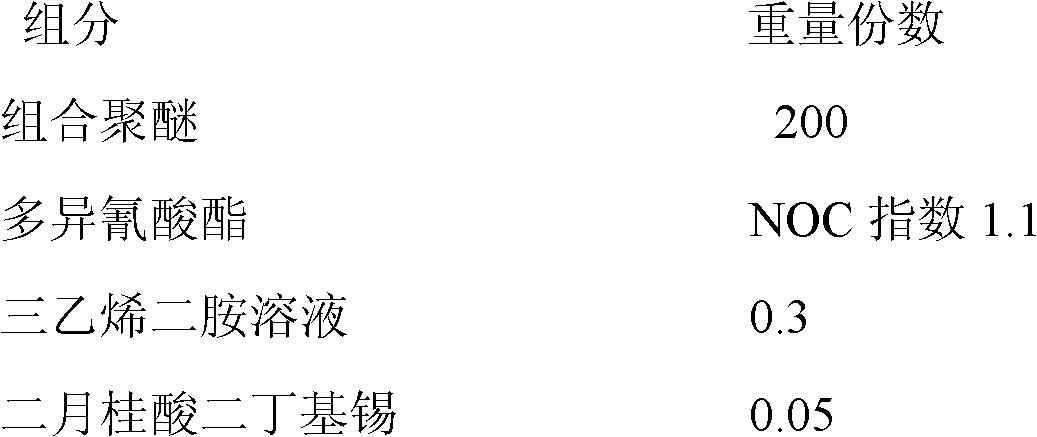

[0018] Composition of the invention

[0019]

[0020] Mix the prepared materials according to the above ratio, stir evenly and pour into the self-made mold for foaming. After the foam plastic is set, place it for a specified time before demoulding.

Embodiment 3

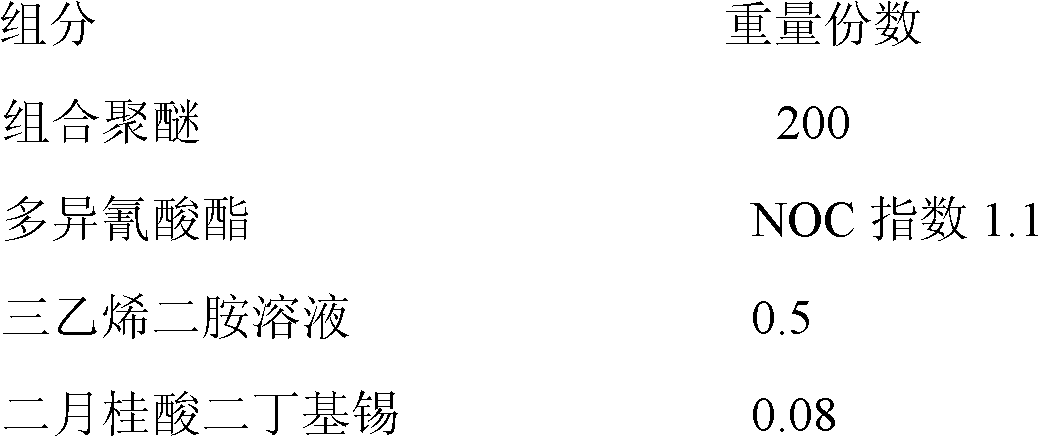

[0022] Composition of the invention

[0023]

[0024] Mix the prepared materials according to the above ratio, stir evenly and pour into the self-made mold for foaming. After the foam plastic is set, place it for a specified time before demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com