Feeding device of inclined-bottom heating furnace

A heating furnace, inclined bottom type technology, applied in heat treatment furnaces, furnaces, furnace types and other directions, can solve the problems of many hidden dangers, low work efficiency, high labor intensity of workers, etc., and achieve a high degree of automation, high work efficiency, and workers The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

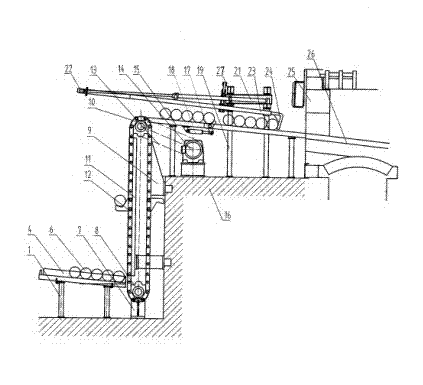

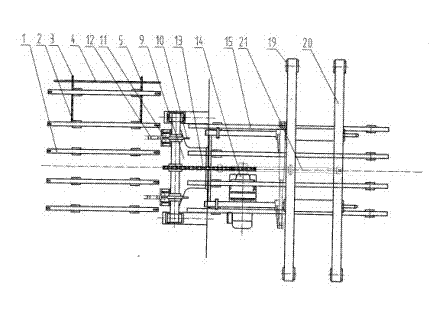

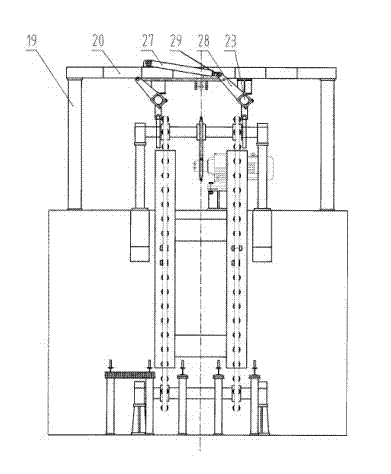

[0012] A charging device for an inclined-bottom heating furnace, comprising an inclined-bottom furnace 25, a feeding high platform 16 is arranged on the left side of the furnace door of the inclined-bottom furnace 25, and a feeding inclined platform 15 is arranged on the feeding high platform 16, The left end of feeding inclined platform 15 is provided with upper sprocket support seat 9, is provided with upper sprocket wheel 10 on upper sprocket support seat 9, and upper sprocket wheel 10 is arranged on the feeding high platform 16 by transmission chain 13 Drive motor 14 is connected, and on the ground below feeding high platform 16 left sides, be respectively provided with material storage inclined stand 1 and lower sprocket fixed seat 7, be provided with lower sprocket 8 on lower sprocket fixed seat 7, on the upper chain A lifting chain 11 is arranged between the wheel 10 and the lower sprocket 8, a finger 12 is arranged on the lifting chain 11, a feeding steel pipe 6 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com