Control system and control method for pattern precognition of weft accumulators

A control method and technology of the weft accumulator, which are applied in the directions of textile, textile and paper making, looms, etc., can solve the problems such as hindering the weaving speed of the loom, affecting the production efficiency, and the yarn feeding speed of the weft accumulator cannot keep up with the weaving speed, etc. Achieve the effect of meeting the speed and ensuring the yarn quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

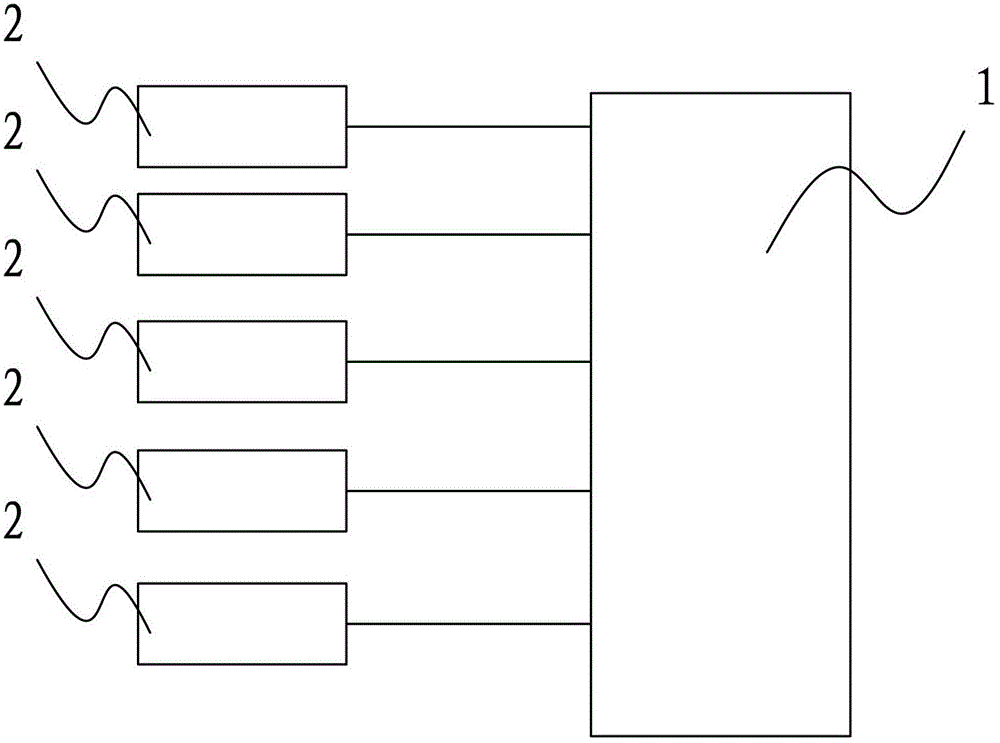

[0022] The present invention can be reformed and formed on the existing loom. The components involved in the present invention mainly include a color selection control unit 1 and a plurality of weft feeder microcontrollers 2 .

[0023] The color selection control unit 1 can be a central processing unit provided in the numerical control system of the loom itself, or a processing chip can be used separately and placed under the numerical control system. The specific internal circuit structure and modules of the color selection control unit 1 are already in the technical category of the numerically controlled loom, so no further description will be made here.

[0024] The weft feeder single-chip microcomputer 2 is an integral part of the weft feeder itself, which can be directly programmed and processed in the present invention, and the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com