Tobacco fiber filter stick, preparation method, and composite filter tip of tobacco fiber filter stick

A tobacco fiber and filter rod technology, applied in the field of tobacco fiber filter rod and its manufacturing, can solve adverse health problems, achieve the effects of saving consumption, novel and unique appearance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

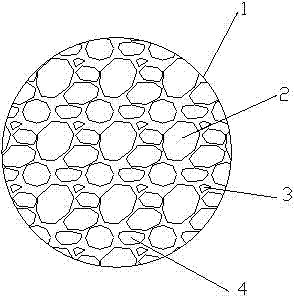

[0028] Such as figure 1 The shown tobacco fiber filter rod is made of a paper filter element containing tobacco plant fiber 3, wood pulp fiber 2, and modified cellulose fiber 4 as the filter material of the filter rod, and is wrapped with forming paper 1 to make it. The ratio of each component to the weight of the filter element is: 5% of the tobacco plant fiber, 50% of the wood pulp fiber, 20% of the modified cellulose fiber, and 25% of other components.

[0029] The tobacco plant fibers 3 are provided by tobacco raw materials such as tobacco dust and tobacco stems; the length of the tobacco plant fibers 3 forms fibers less than 5mm in the pulp. Modified cellulose fibers 4 are chopped fibers with a length of 10mm-20mm.

[0030] The other ingredients may include Chinese herbal medicines or flowers that play a role in health care and improve the taste of smoke, as well as auxiliary materials such as fillers for papermaking.

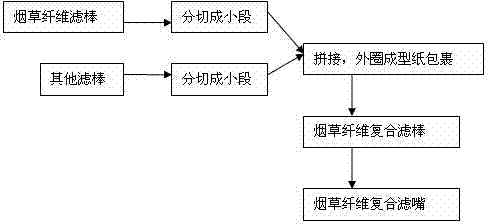

[0031] use as figure 2 Tobacco plant fiber 3, wo...

Embodiment 2

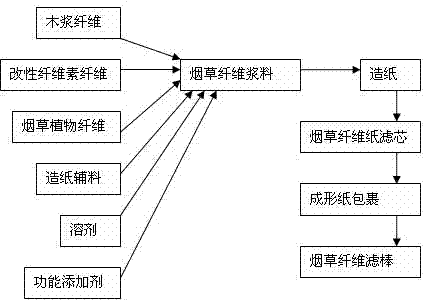

[0033] use as image 3 The process of cutting the tobacco fiber filter rod in Example 1 into 10mm long segments, then cutting the ordinary filter rod into 15mm segments, splicing them together, and wrapping the outer ring with the same molding paper to form tobacco fiber composite The filter rod, or after being cut by a cigarette rolling machine, becomes a tobacco fiber composite filter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com