Steel-concrete composite cylindrical foundation structure and construction method thereof

A cylindrical foundation and concrete technology, applied in the field of basic structure, can solve the problems such as the thickness of the cylindrical wall and the subsidence is not in place, and achieve the effects of shortening the construction period, fast subsidence and reducing the engineering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

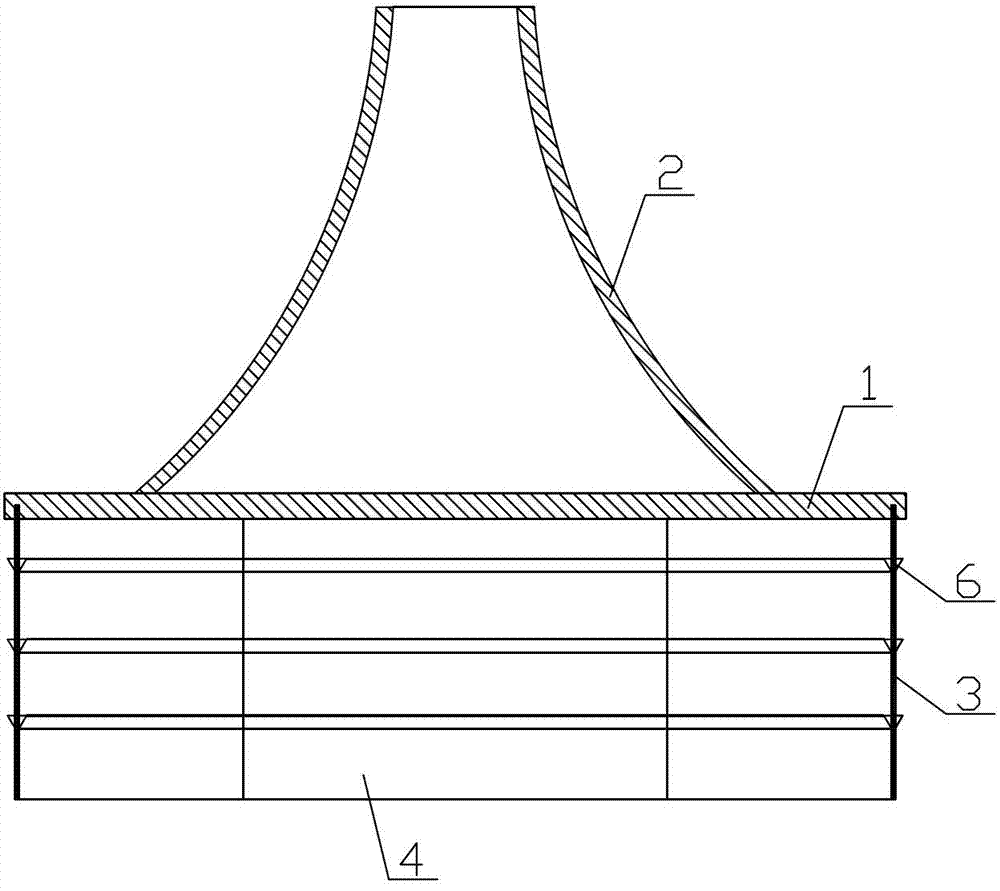

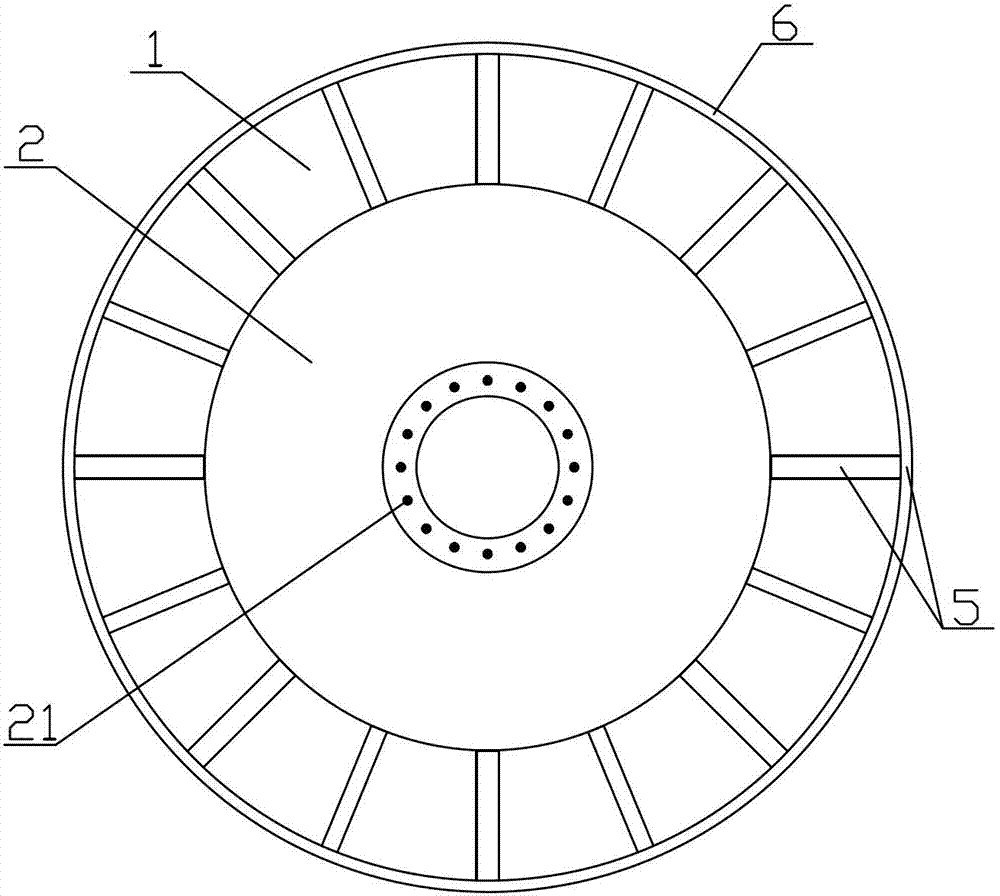

[0032] Such as figure 1 and figure 2 As shown, this embodiment discloses a steel-concrete composite tubular foundation structure, which is mainly composed of a concrete roof 1, a concrete tubular transition section 2, a steel tubular wall 3, and steel partitions in the inner space of the steel tubular wall 3. The deck 4 constitutes.

[0033] The concrete roof 1 is a circular sheet structure with a diameter of 30m and a thickness of 0.3m. The usual diameter selection range of the concrete roof 1 is 10-50m, and the thickness selection range is 0.2-0.6m.

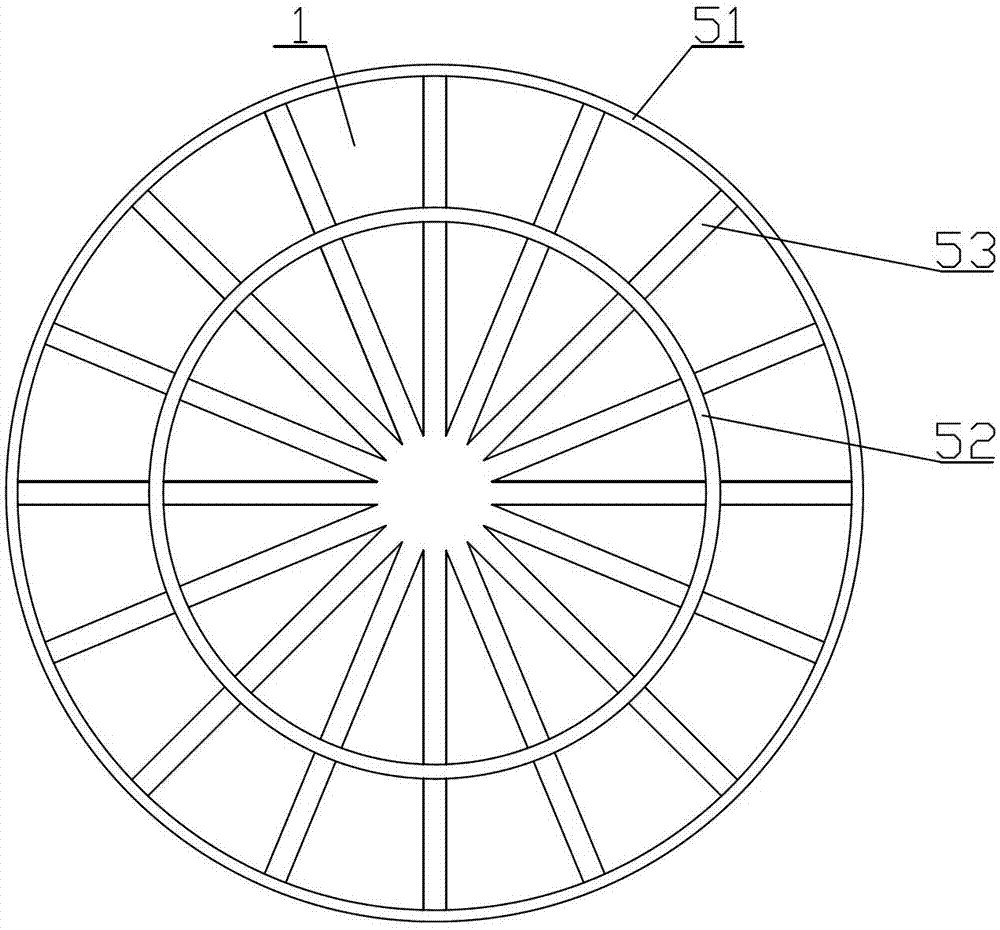

[0034] The upper surface of the concrete roof 1 is distributed with a structural beam system 5 capable of ensuring the rigidity of the concrete roof 1 , and the bottom surface of the structural beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com