Equipment foundation standard mould of multifunctional transformer substation

A technology based on equipment foundation and standard mold, applied in basic structure engineering, construction and other directions, can solve the problems of large construction scope and operation area, affecting the civilized construction environment on site, easy unbalanced grouting and pouring ratio, etc. The working area is small, which is conducive to wide use and promotion, and is not easy to be out of shape and deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the drawings.

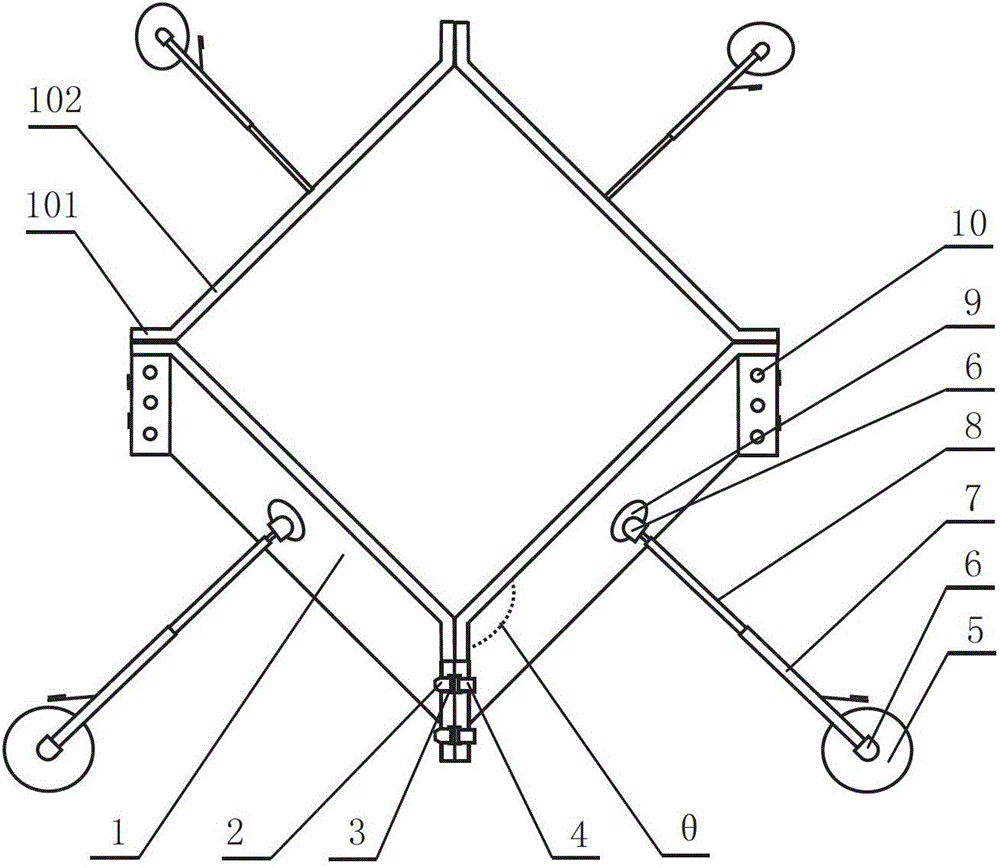

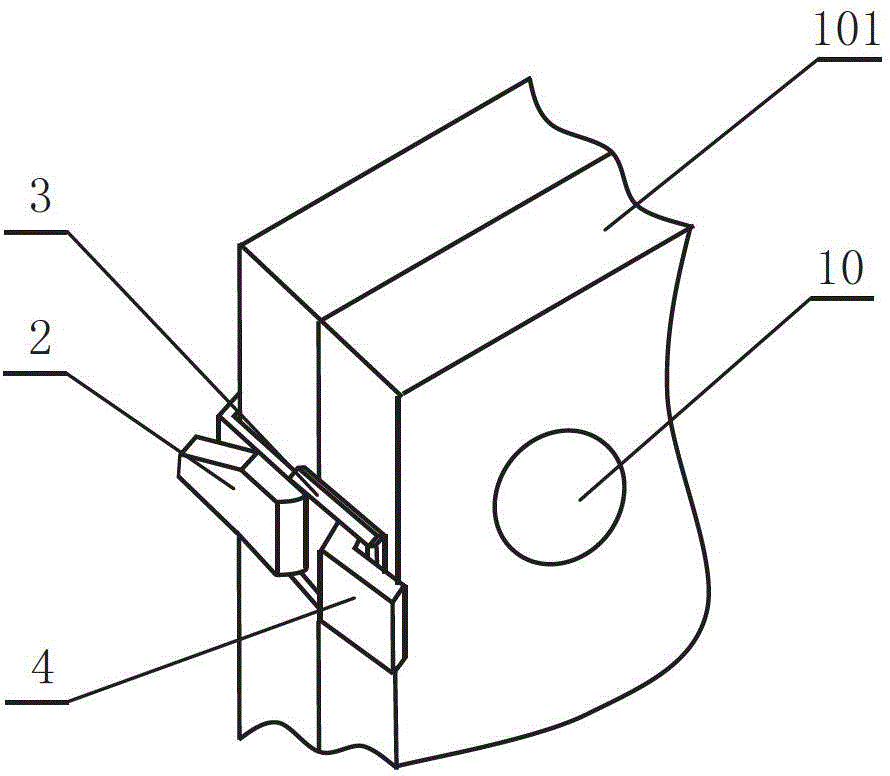

[0019] Such as figure 1 As shown, the present invention is composed of four figure-eight templates 1, each template 1 includes two sides 101 and a straight side 102, the angle θ between the two sides 101 and the straight side 102 is 135 0 One side 101 is provided with a fixed mother board buckle 2, a fixed mother board buckle 2 is provided with a movable buckle ring 3, and the other side 101 is correspondingly provided with a movable daughter board buckle 4. The fixed mother board buckle 2, the movable buckle ring 3, and the movable daughter board buckle 4 are two groups.

[0020] Combine figure 2 As shown, the sides 101 of two adjacent eight-shaped templates 1 are aligned in pairs, and the fixed mother board buckle 2 and the movable sub-board buckle 4 are buckled together by the movable buckle ring 3.

[0021] A hydraulic device is provided on the outside of the template 1, and the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com