Cast-in-situ heat preservation and heat isolation beam, column or shear wall and construction method thereof

A technology of thermal insulation and thermal insulation panels, applied in thermal insulation, building components, buildings, etc., can solve the problems of difficult construction, high cost, poor durability and thermal insulation, and achieve the ability to improve the vertical relative displacement and ensure The effect of stability and strengthening connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

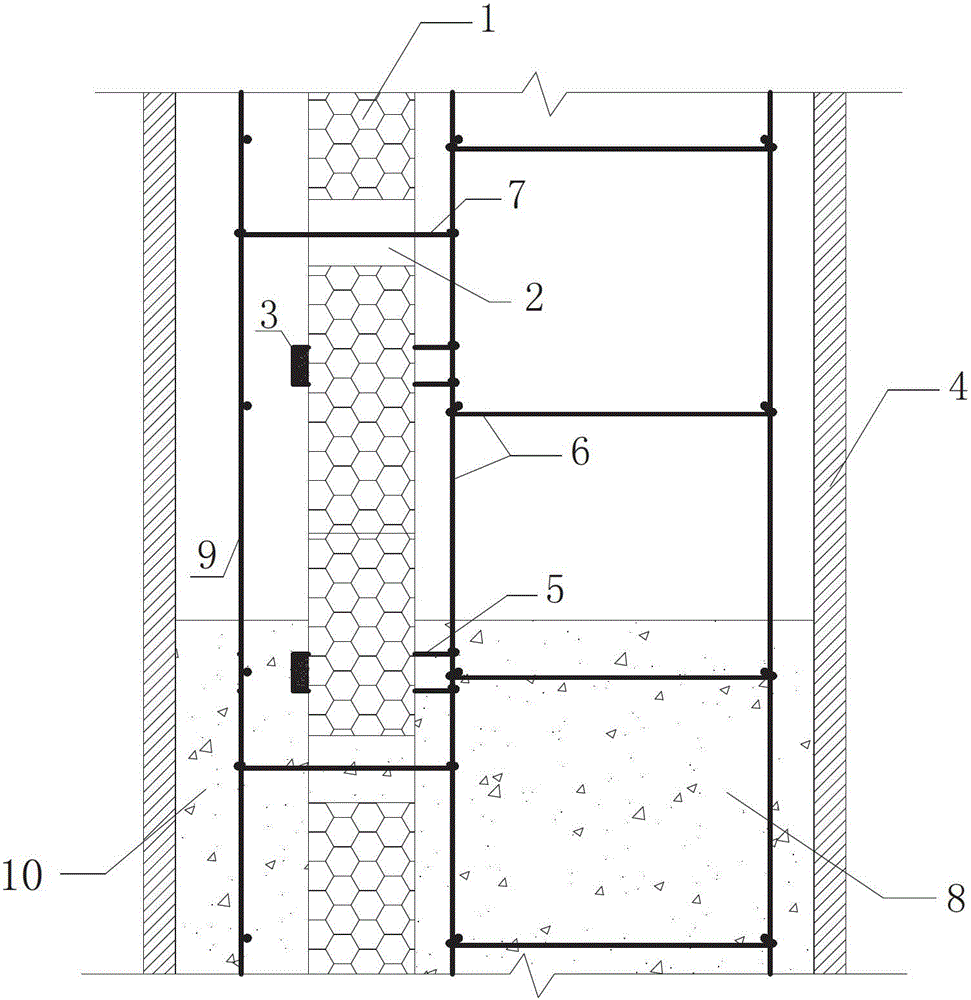

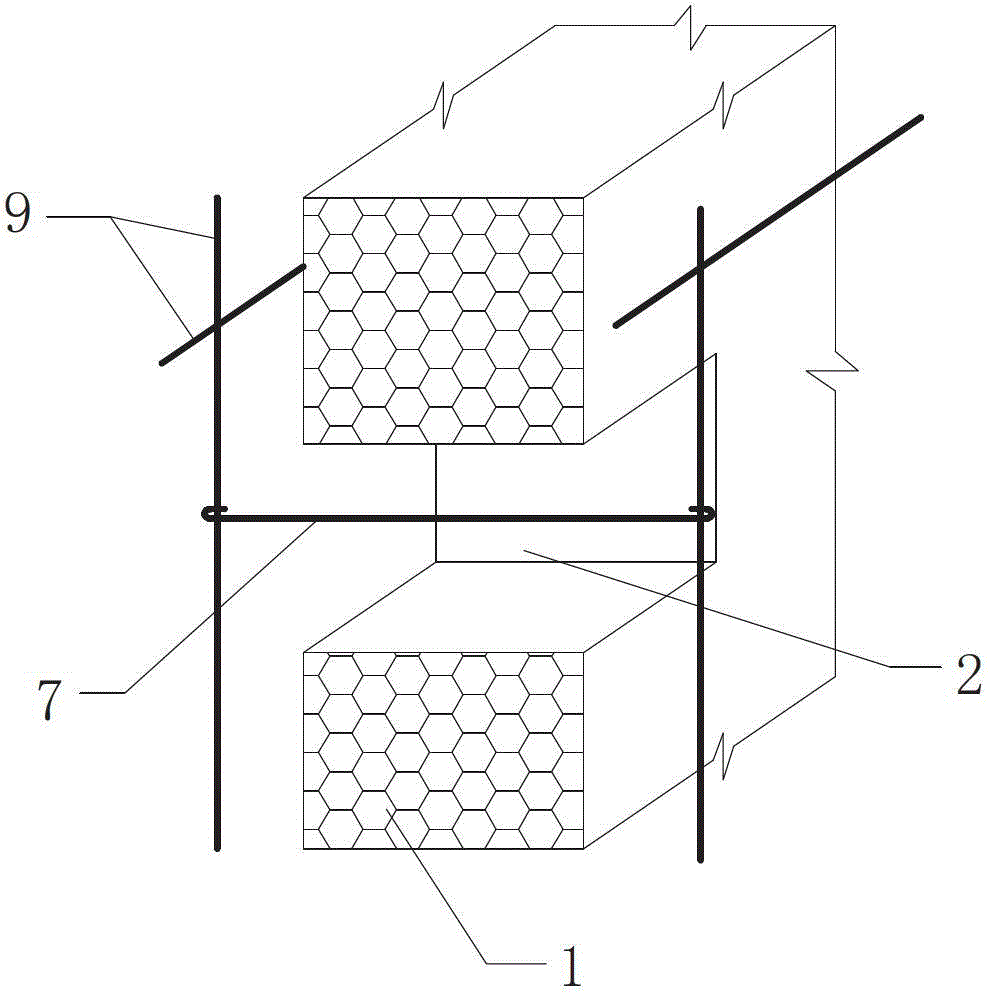

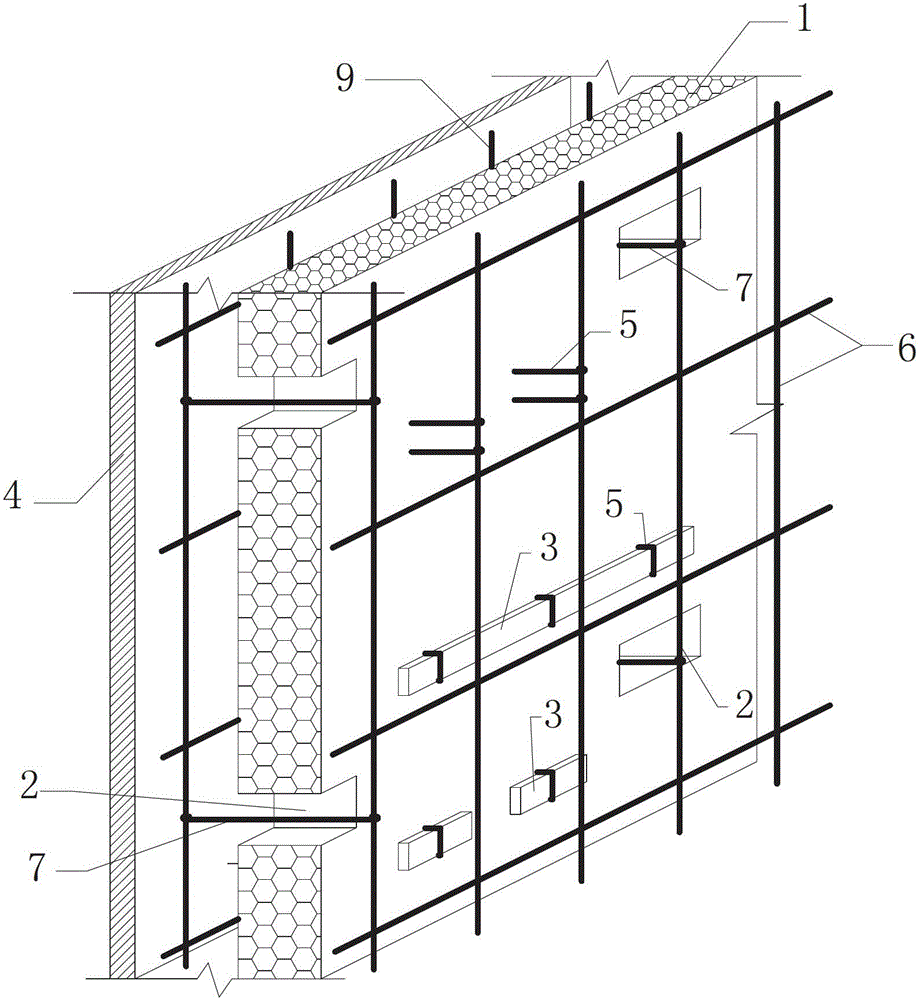

[0016] The present invention is attached Figures 1 to 5 shown.

[0017] refer to figure 1 — figure 2 , the cast-in-place thermal insulation beam, column, shear wall, the thermal insulation board 1 has holes 2, the holes 2 are evenly and regularly arranged on the thermal insulation board 1, and the cross-sectional form of the holes 2 is a polygon, or a circle, Or oval, or semicircular. Holes 2 are provided on the thermal insulation board 1. When pouring concrete, the concrete can flow from one side of the thermal insulation board 1 to the other side. The effect of the lateral concrete pressure difference; the reinforcing ribs 7 set in the hole and the concrete in the hole 2 form a reinforced concrete short column, which strengthens the connection force of the inner and outer concrete, reduces the vertical relative displacement of the inner and outer concrete, and makes the inner concrete 8 and the outer concrete 10 can cooperate with the force, and also ensure the stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com