Intelligent hydraulic frictional damping device

A technology of friction damping and friction damper, which is applied in the direction of filter screen, grid, solid separation, etc., can solve problems such as difficult to reach, manual replacement, easy corrosion of adjusting bolts, etc., to achieve suppression of resonance amplitude, long service life, and easy installation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

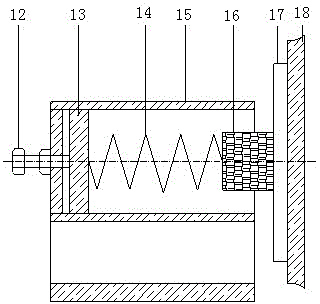

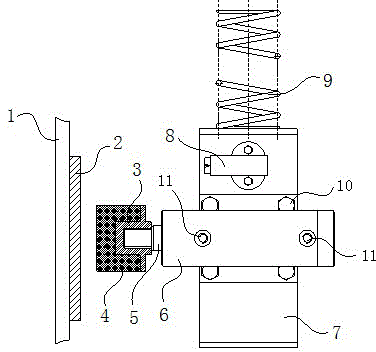

[0019] Such as figure 2 As shown, the intelligent hydraulic friction damping device is composed of four sets of hydraulic friction dampers and a set of integrated PLC control cabinet; the hydraulic friction damper includes a support 10, a hydraulic cylinder 6, a piston rod 5, and a rubber block 3 , block seat 4, friction plate 2, sensor 8 and other components, the hydraulic cylinder block 6 is connected with the support 10, the support 10 is installed on the vibrating screen support 7 below the vibrating screen support spring 9, and the piston rod 5 is installed on the hydraulic cylinder The rubber block 3 is installed on the block seat 4, the block seat 4 is fixed on the front end of the piston rod 5, the friction plate 2 is fixed on the outside of the side plate 1 of the industrial vibrating screen, and the sensor 8 is installed on the vibrating screen. The screen support 7 is connected with the integrated PLC control cabinet by the data line; four sets of hydraulic frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com