Counter-burning wet combustion furnace

A back-burning and combustion furnace technology, which is applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of insufficient safety of steam furnaces, inability to fully burn swill, and a small amount of water and gas that cannot be fully utilized, so as to avoid flames Extinguishment, low production cost, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

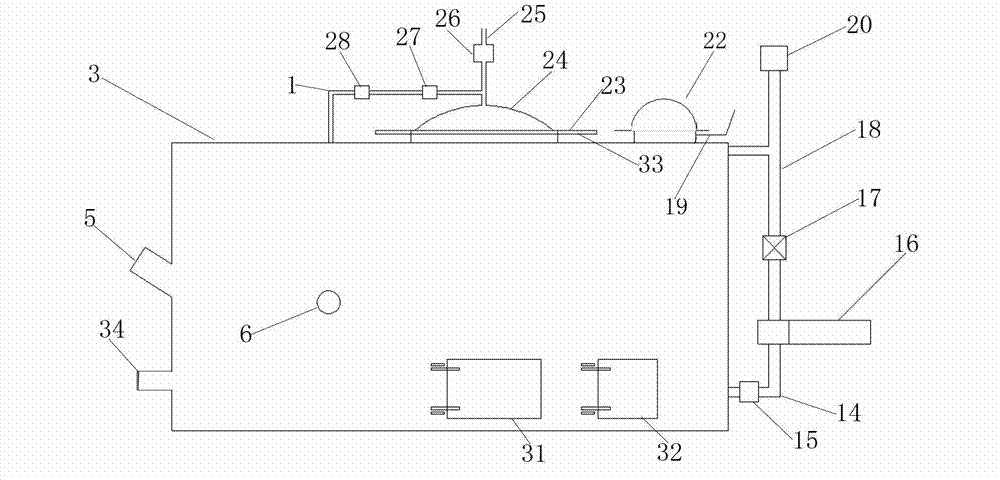

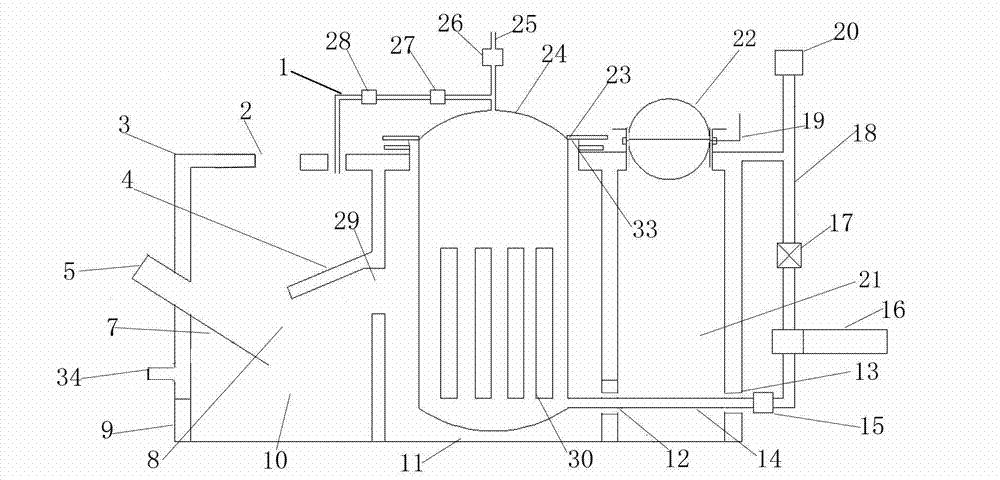

[0022]A reverse burning type wet combustion furnace, comprising a furnace body 3, two furnace walls are vertically arranged inside the furnace body 3, and the two furnace walls divide the inside of the furnace body 3 into three cavities, and the cavities are furnace chambers in turn 10. Heat exchange chamber 11 and flue 21; the lower side wall of the furnace 10 is provided with a slag outlet, and the slag outlet is provided with a slag discharge door 9; the lower part of the heat exchange chamber 11 is provided with a heat exchange chamber dust removal port; A heat exchange chamber dust removal door 31 is provided on the ash opening, and a flue dust removal port is provided at the bottom of the flue 21; a flue dust removal door 32 is provided on the flue dust removal port; There is a smoke inlet 29 in the middle of the wall; a smoke exhaust port 12 is provided at the lower part of the furnace wall between the heat exchange chamber 11 and the flue 21; a hole 13 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com