Tooth roller furnace biomass particle removal burning boiler

A toothed roller furnace, material technology, applied in the field of biomass fuel combustion equipment, to achieve the effects of high heat energy utilization, sufficient fuel combustion, and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

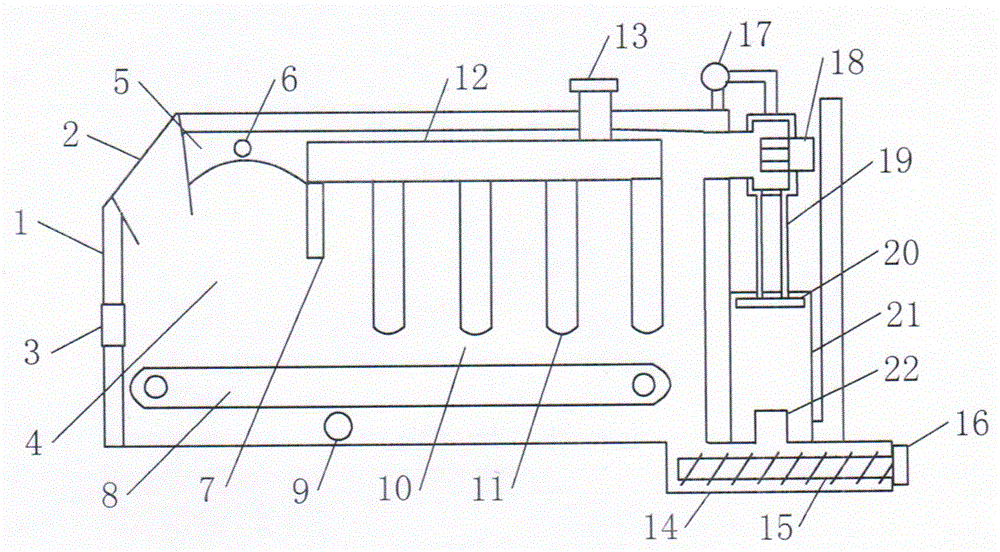

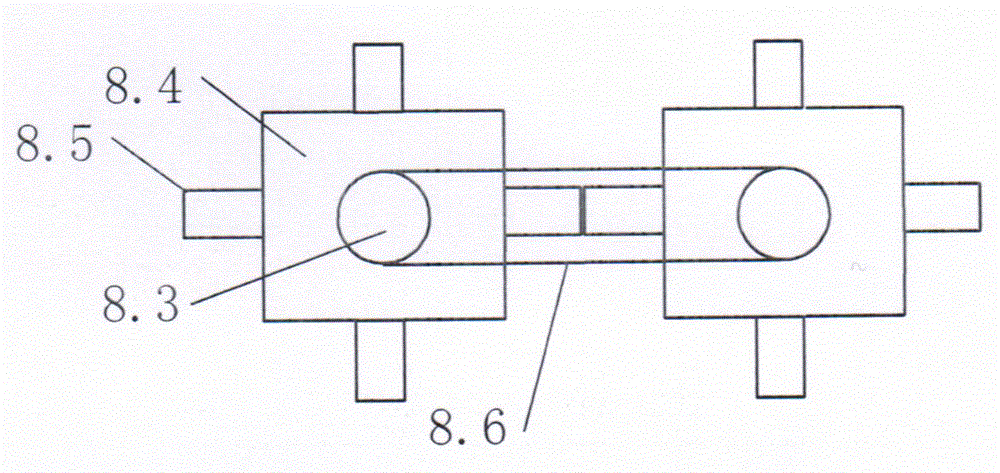

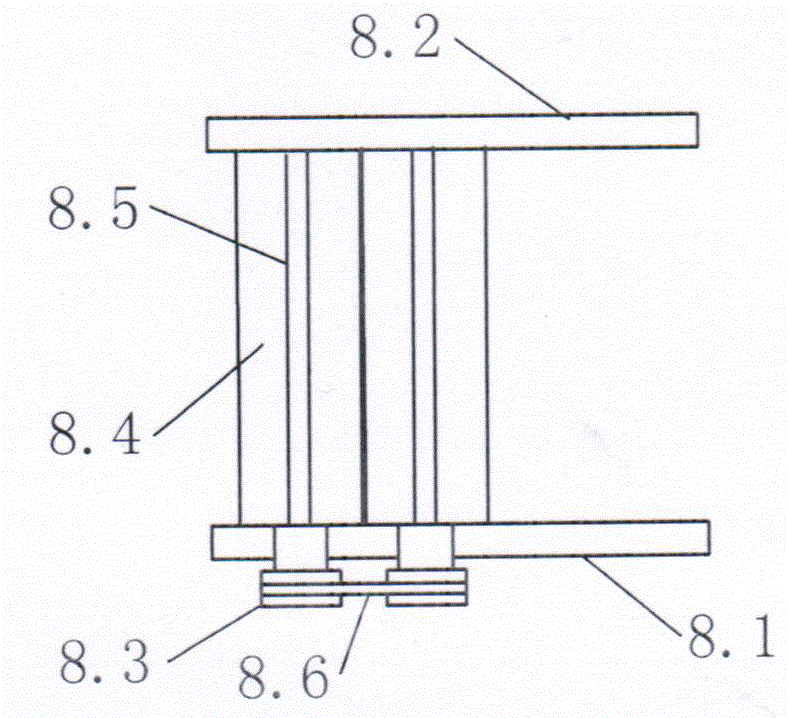

[0012] As shown in the figure, a front observation door 3 is provided on the front wall of the furnace body 1, a fuel inlet 2 is provided on the upper side of the front part of the furnace body, and a baffle 7 is arranged in the furnace body. As the front combustion chamber 4, the upper part of the front combustion chamber is provided with an arched furnace arch 5, and the furnace arch is provided with a vent 6. The main combustion chamber 10 is formed between the rear side of the baffle plate and the rear furnace body wall. A vertical heat exchange tube 11 is installed between the indoor and the water jacket wall of the furnace body. The upper end of the heat exchange tube is connected to the thermal medium concentration chamber 12 arranged in the furnace body, and the thermal medium output is connected to the upper part of the thermal medium concentration chamber. Pipe 13 is provided with a pressure water source pipe 17 on the upper part or one side of the furnace body. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com