Environmental-friendly biomass particle combustion equipment with dedusting function

A technology of biomass pellets and combustion equipment, which is applied to combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of reducing fuel thermal efficiency, low boiler thermal efficiency, and large fuel heat loss, so as to make up for insufficient combustion, The effect of high boiler thermal efficiency and sufficient fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

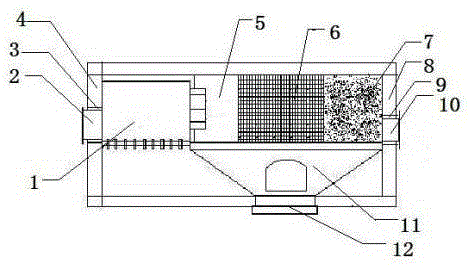

[0012] This embodiment provides an environmentally friendly biomass particle combustion equipment with dust removal function, which is characterized in that: the environmental protection biomass particle combustion equipment with dust removal function includes a combustion chamber (1), a feed port (2) , the first sealing ring (3), front end cover (4), cooling chamber (5), filter chamber (6), split chamber (7), rear end cover (8), second sealing ring (9), exhaust Mouth (10), ash collection bin (11), ash removal valve (12);

[0013] Among them: the combustion equipment has a combustion chamber (1), a cooling chamber (5), a filter chamber (6), a flow distribution chamber (7) and an ash collection bin (11), a combustion chamber (1), a cooling chamber (5 ), the filter chamber (6), and the shunt chamber (7) are sequentially connected to the upper half of the equipment, and the lower half is provided with an ash collection bin (11), and a dust removal valve (12) is provided under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com