Evaporation mixing combustion mode for liquid fuel and combustion chamber therefor

A liquid fuel, mixed combustion technology, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of air pollution, insufficient combustion, etc., and achieve the effect of sufficient fuel combustion, reasonable combustion method and less exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

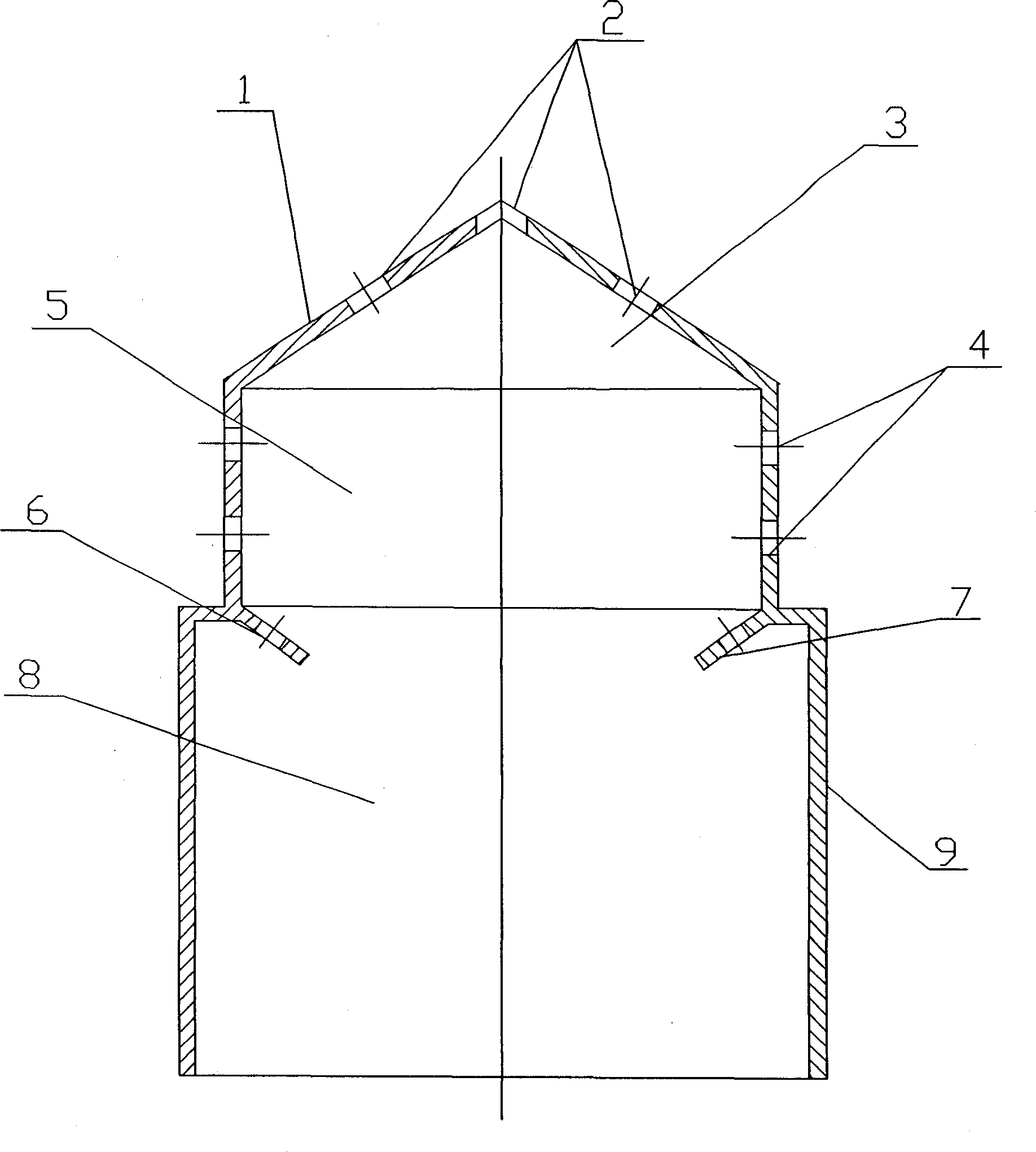

[0018] figure 1 , the combustion chamber 9 is divided into three areas: evaporation zone 3, mixing zone 5 and combustion zone 8. The fuel is gasified in the evaporation zone 3, which is brought into the evaporation zone 3 by the primary air, and then through a reasonable secondary air organization, the gasified liquid fuel is fully mixed in the mixing zone 5, and mixed The zone 5 is close to the auto-ignition temperature, and by setting the necking plate 7 and the vent hole 6 between the mixing zone 5 and the combustion zone 8, the fuel can achieve homogeneous lean combustion in the combustion zone 8, thereby controlling Nox pollution The generation of things.

[0019] The evaporation zone 3 is near the closed end of the combustion chamber 9 and is mainly the area where the fuel evaporates or gasifies. At the closed end of the combustion chamber 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com