Backfired Boiler

A boiler and back-burning technology, applied in the field of boilers, can solve the problems of firewood fuel humidity, high size requirements, troublesome waste cleaning, high fuel cost, convenient filling method and slag cleaning, convenient use of automatic blanking, and low fuel requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

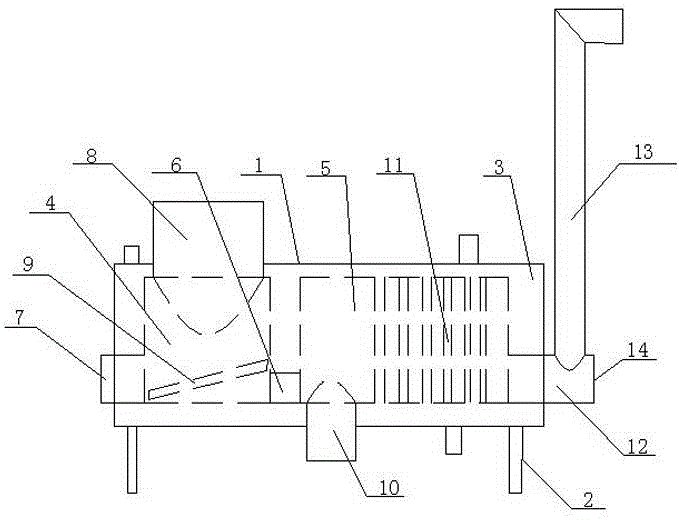

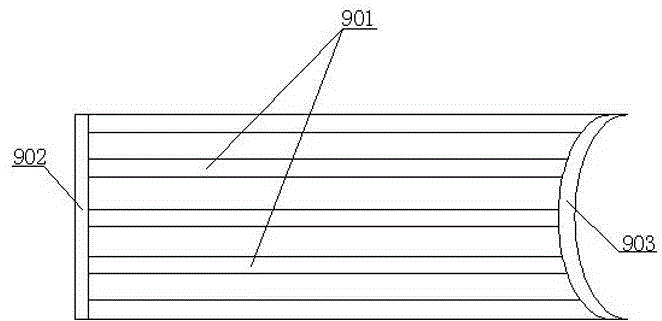

[0018] As shown in the figure, an inverted firing boiler includes a boiler body wrapped by a furnace wall 1 and a bracket 2 for supporting the boiler body. The furnace wall 1 has a double-layer structure, and the space formed by the double-layer furnace wall is a water storage room. 3. A plurality of water pipe interfaces can be provided on the furnace wall. The boiler body is divided into a combustion chamber 4 and a heat collection chamber 5 by the furnace wall. The combustion chamber 4 and the heat collection chamber 5 are arranged horizontally, and through the The fire passage 6 is connected, and an air inlet 7 is arranged on the furnace wall on one side of the combustion chamber 4, and the air inlet 7 is set correspondingly to the fire passage 6. A hopper 8 is arranged above the combustion chamber 4, and the feeding port of the hopper is connected with the combustion chamber. The fuel automatically falls into the combustion chamber by gravity, and a fire grate 9 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com