Multifunctional oil gas energy-saving stove

An energy-saving stove and multi-functional technology, which is applied in the field of oil and gas stoves, can solve the problems of energy waste of ordinary stoves, and achieve the effects of clean and beautiful kitchens, broad market prospects, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

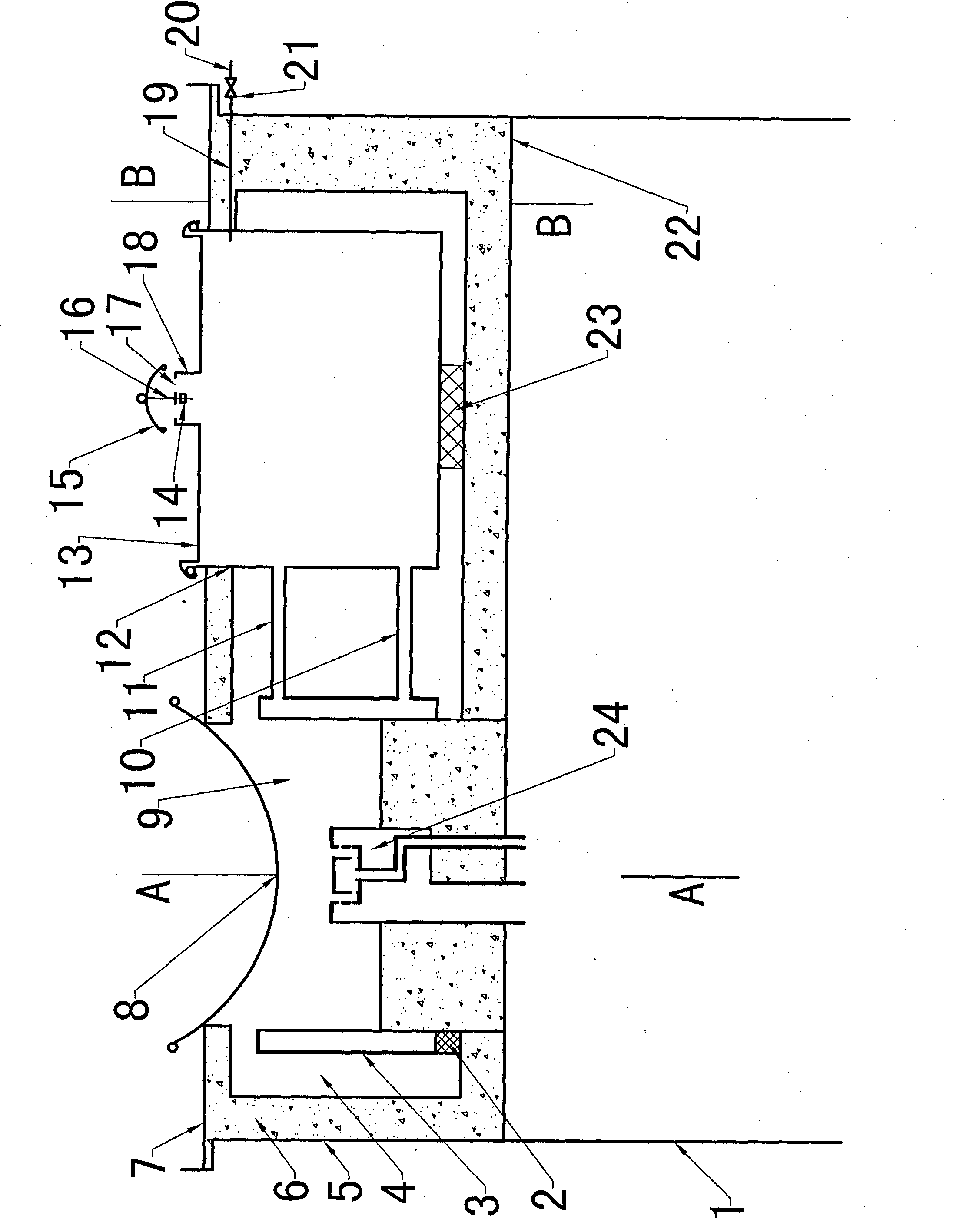

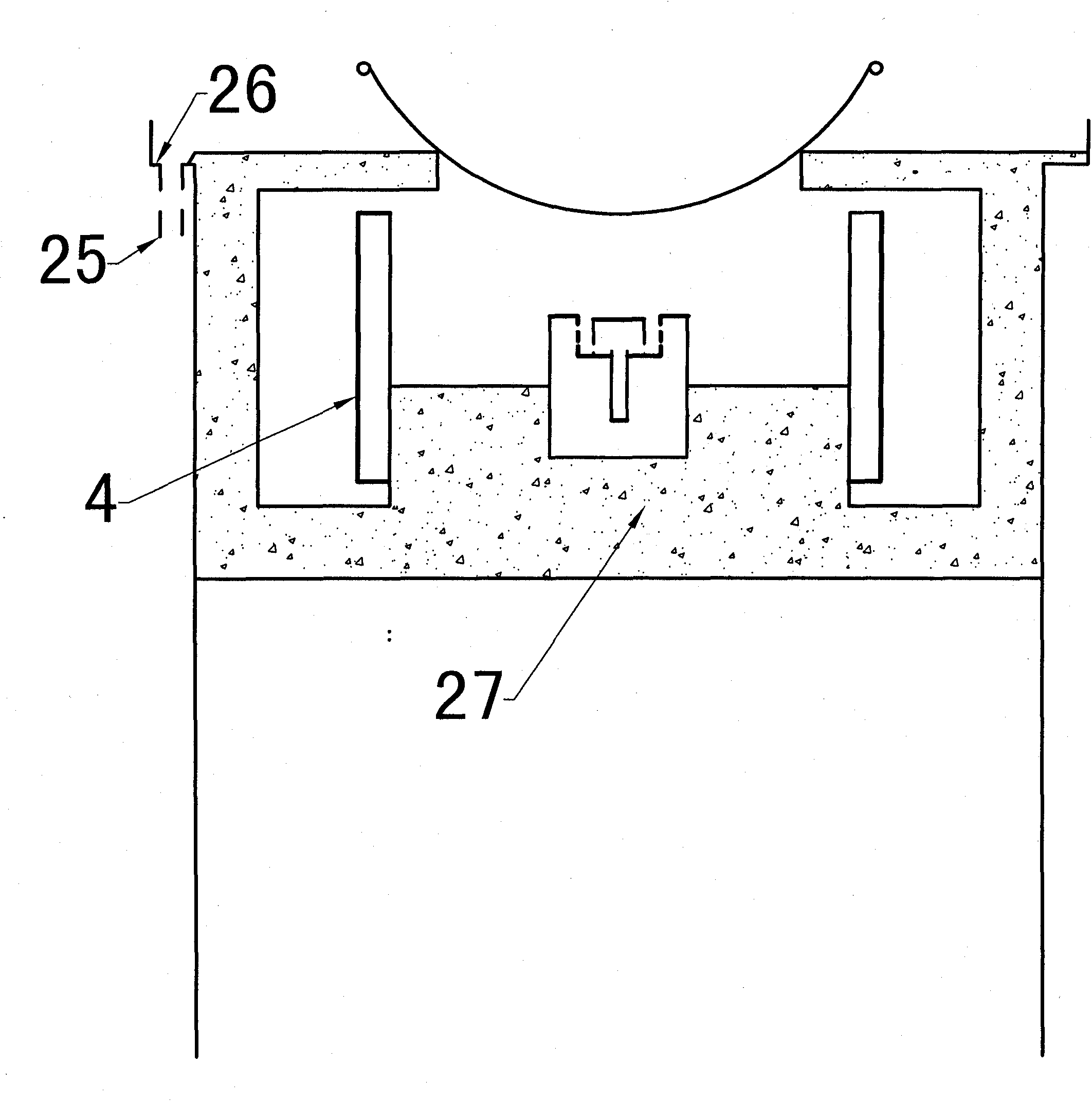

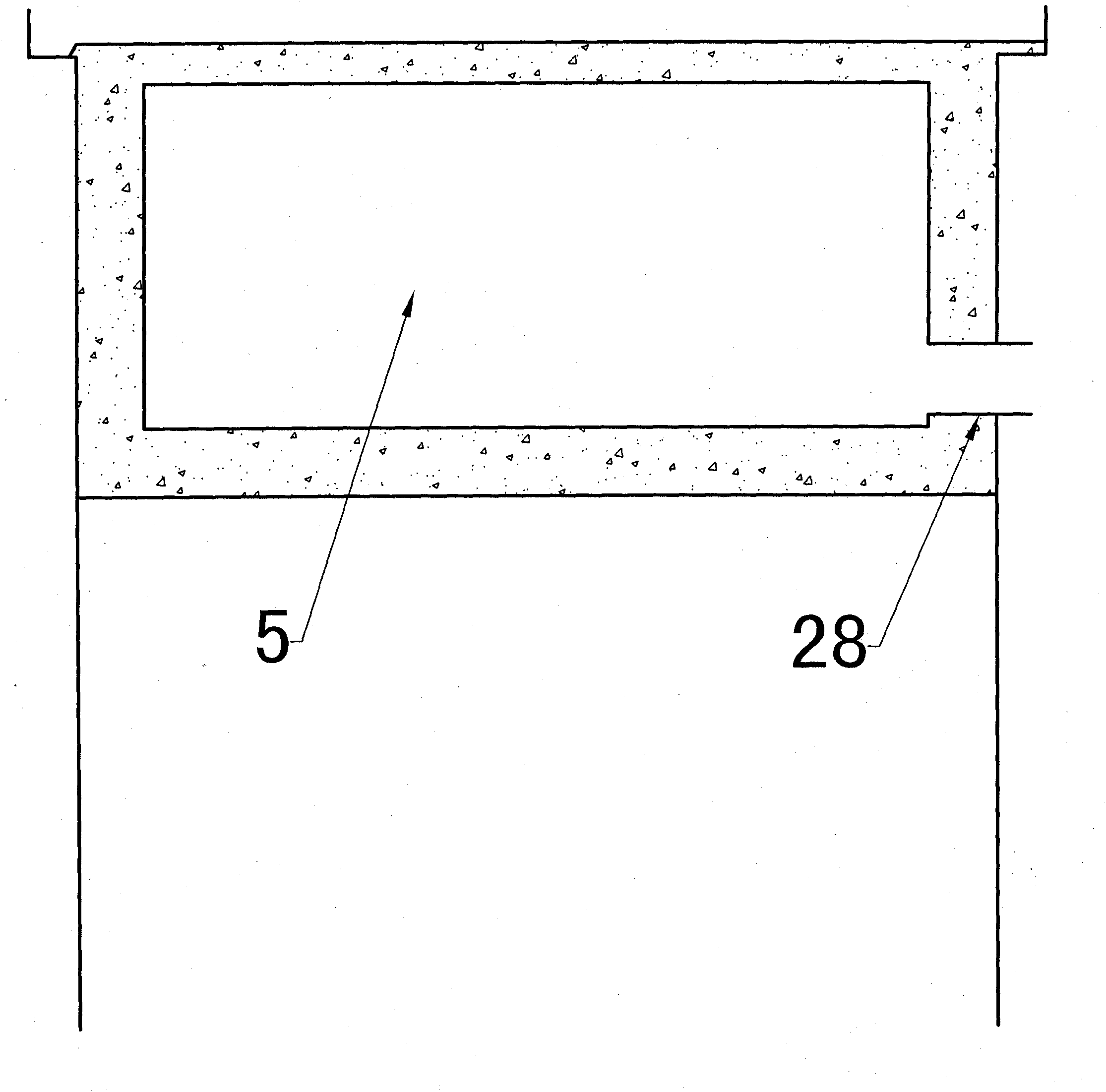

[0023] The accompanying drawings describe the structural form of a multifunctional oil and gas energy-saving stove. The leg 1 is fixed with the shell 5; the shell and the base plate 22 are fixed together; there is an insulating layer 6 inside the shell; there is a cavity in the insulating layer, and a heat exchanger and a water tank having a gap with the insulating layer are installed in the insulating layer cavity 4 and its connecting pipe; heat exchanger 3 has insulation material 27 in the middle and lower part; heat exchanger support 2 is fixed with the bottom plate through the insulation layer, and heat exchanger support 2 fixes the heat exchanger in the cavity of the insulation layer , the upper part of the heat exchanger communicates with the upper part of the water tank 12 through the upper circulation pipe 11, and the lower part of the heat exchanger communicates with the lower part of the water tank 12 through the lower circulation pipe 10; the steam output pipe 20 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com