Non-oxidation split charging device and non-oxidation split charging method for manufacturing alkali-metal high-temperature heat tubes

A high-temperature heat pipe and alkali metal technology, applied in the field of heat pipes, can solve problems affecting temperature control, affecting the final performance of heat pipes, and affecting filling stability, etc., to reduce trouble, avoid the influence of air leakage and partial pressure, and improve the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

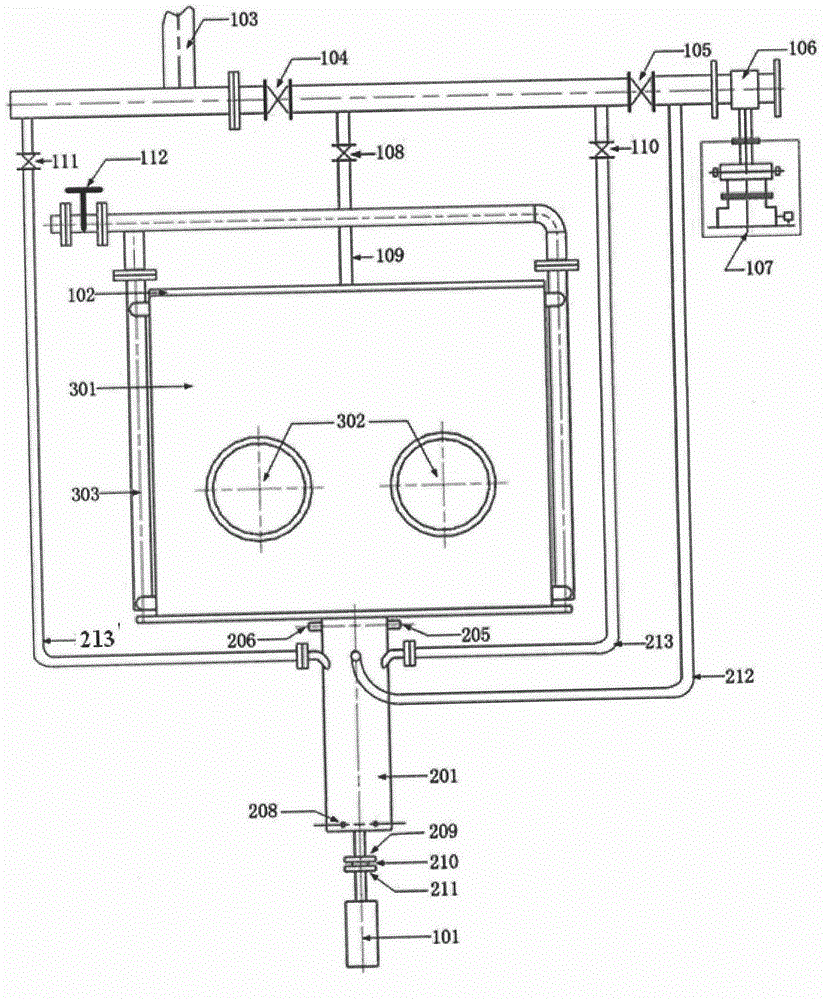

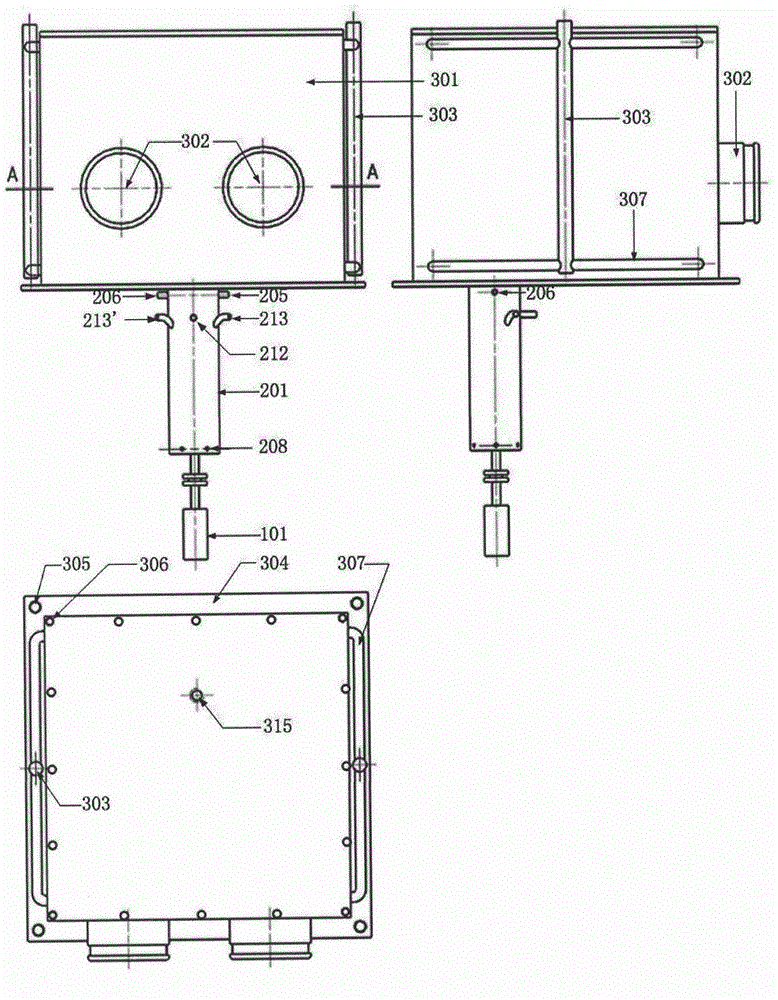

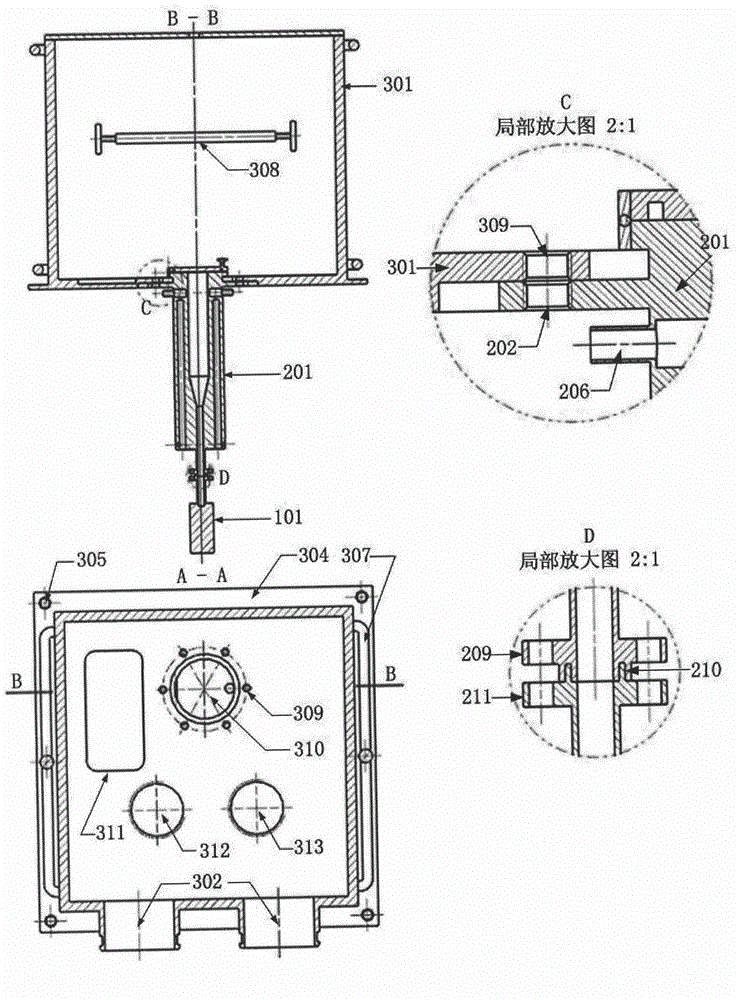

[0077] A device for preparing alkali metal high-temperature heat pipes, such as figure 1 As shown, the device includes a high-temperature heat pipe 101, a high-temperature storage tank 201, a glove box 301, an ultra-high vacuum molecular pump unit 107, pipelines and valves; the glove box 301 includes an exhaust main pipe 303;

[0078] Wherein, the pipeline includes a main air intake pipe 103, a branch air extraction bypass 212, an intake bypass 213 and an air outlet bypass 213';

[0079] The valves include a first ultra-high vacuum sealing valve 104, a second ultra-high vacuum sealing valve 105, a third ultra-high vacuum sealing valve 106, a fourth ultra-high vacuum sealing valve 108, a fifth inlet valve 110, a sixth inlet valve 111 and The seventh exhaust valve 112;

[0080] The main intake pipe 103 communicates with the outlet bypass 213' through the sixth intake valve 111;

[0081]The main intake pipe 103 communicates with the intake bypass 213 through the first ultra-vac...

Embodiment 2

[0125] Such as Figure 7 As shown, the difference from Embodiment 1 is that the exhaust guide pipe 307 is inside the glove box 301 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com