Pressure guiding tube blockage detecting system and detecting method

A diagnostic method and diagnostic system technology, applied in pipeline systems, measuring fluid pressure, testing of machine/structural components, etc., can solve problems such as difficulty in utilization, reduction of amplitude, and difficulty, so as to improve sensitivity and easily change pressure sloshing , easily detectable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0102] In Embodiment 1, the container 10 is set as the deformation rate increasing unit, but as Figure 10 As shown, by increasing the inner diameter of part or all of the pressure guiding tube 3, the volume of the fluid 7 located between the blockage (occlusion) 6 and the pressure signal generator 1 can also be increased to obtain the same pressure as in the first embodiment. Effect.

[0103] Figure 10 Among them, the corner of the L-shaped curved pressure guiding tube 3 is used as a site that is easy to be blocked, and the inner diameter of the pressure guiding tube 3 on the inner side than the corner is increased. For example, when the inner diameter is tripled, the volume occupied by the fluid and its deformation amount are nine times larger. This reference example 1 is also the same as the first embodiment, and is mainly effective for compressive fluids. In addition, the magnitude of the effect depends on the position of the blockage (occlusion) 6 .

[0104] [Embodim...

reference example 2

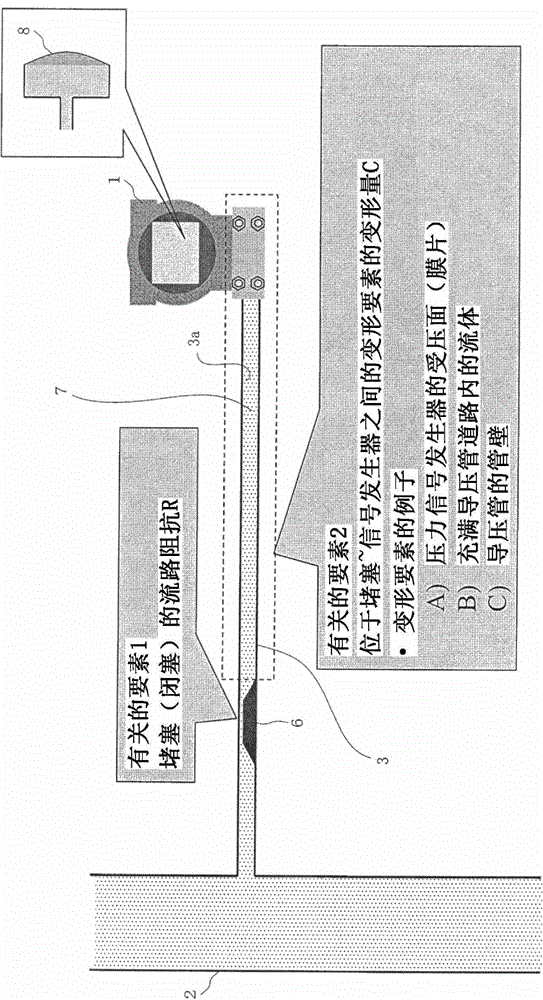

[0115] In Embodiment 2, a member 13 having a diaphragm 12 is provided as a deformation rate increasing unit, but in Figure 13 In the shown structure, the same effect as that of the second embodiment can be obtained by using a material or a structure that is easily deformed by a pressure change for the pressure guide tube 3 .

[0116] When the pressure of the fluid in the pressure guiding tube 3 changes, the pressure guiding tube 3 expands and contracts in the diameter direction. That is, the diameter becomes larger as the pressure increases, and the diameter decreases as the pressure decreases. The pressure guiding pipe 3 is generally a pipe made of metal. Also, the amount of expansion and contraction with respect to pressure changes is often small. Here, if the material of the pressure guiding tube 3 is made of more easily deformable resin or soft metal, or the thickness of the wall 3a of the pressure guiding tube 3 is reduced, the deformation rate of the pressure guiding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com