Multichannel liquid sample reagent rapid charging reactor

A liquid sample and multi-channel technology, applied in the field of medical testing, can solve the problems of complex structure, high precision and low efficiency of the injector, and achieve the effect of great application value, cost saving and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

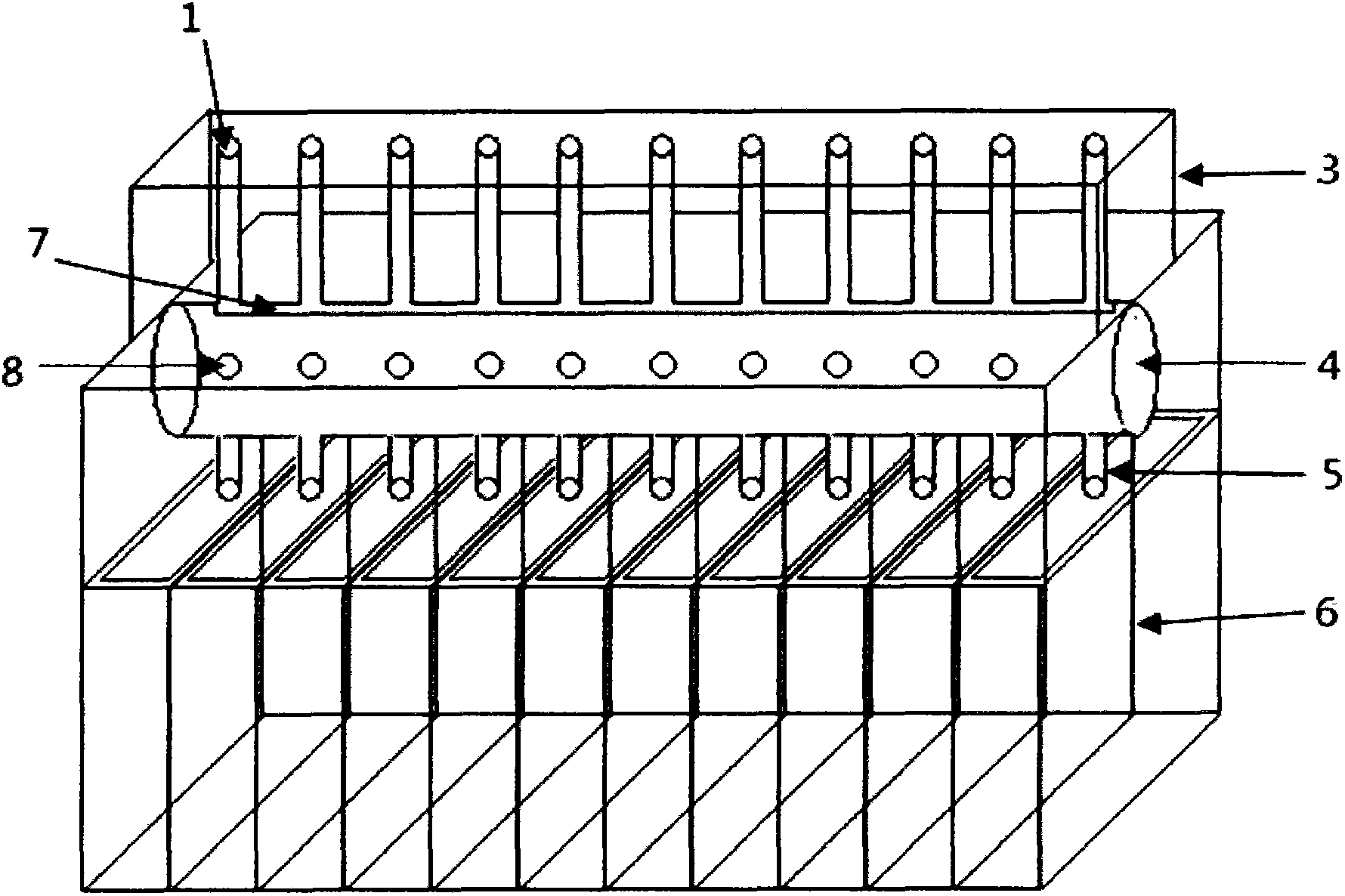

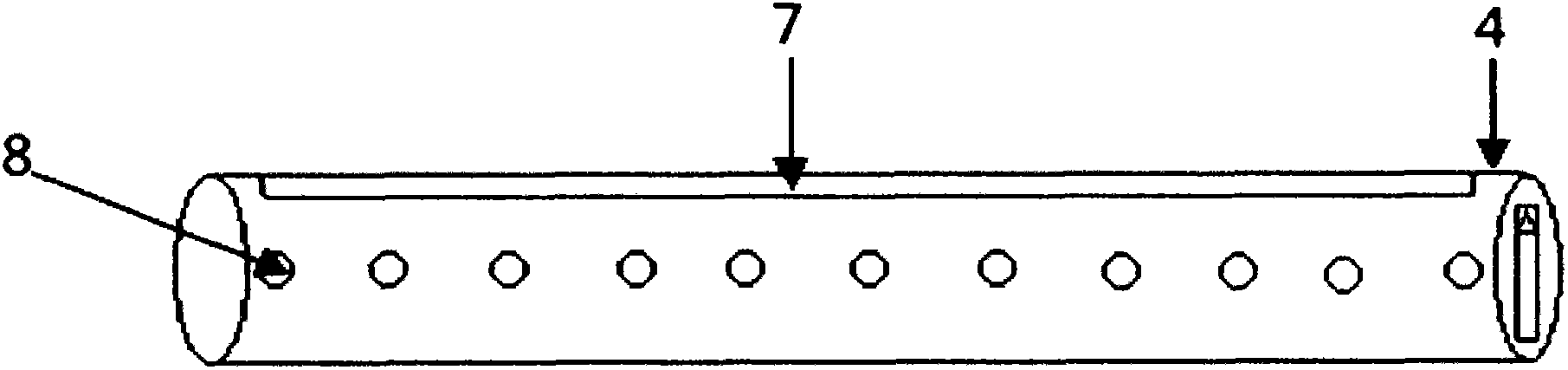

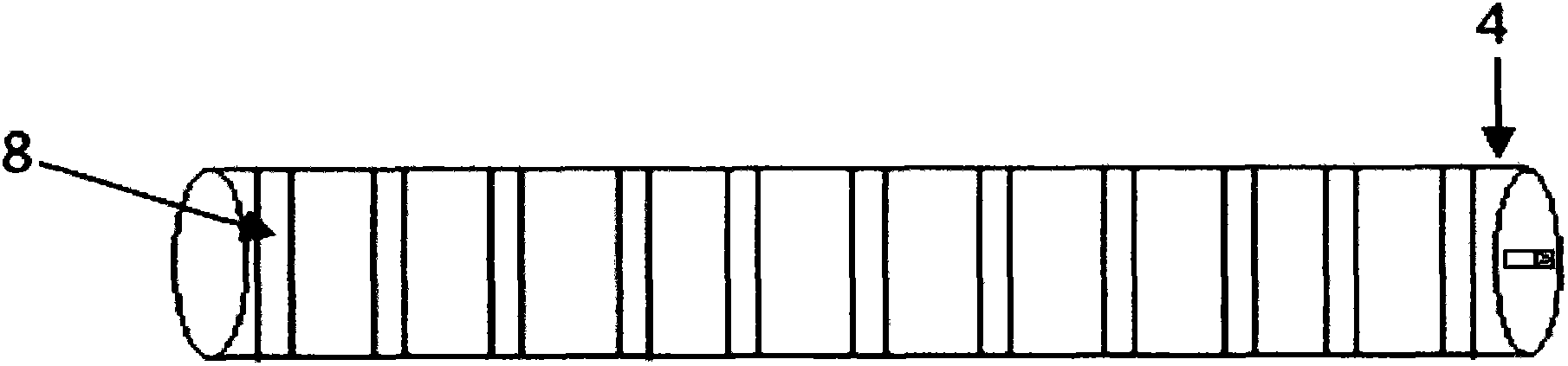

[0023] Such as figure 1 As shown, a rapid sample reagent filling reactor of the present invention that can be used for single reagent determination includes a sample reagent filling device 3, and a multi-channel spacing is set on a transparent plastic plate in the sample reagent filling device 3 Equal sample quantification well 1. At the lower end of the sample quantitative hole 1 is provided a cylindrical and transversely placed rotating shaft 4, a rotating shaft sample communication groove 7 and a rotating shaft sample conducting hole 8 are opened on the rotating shaft 4, and a rotating shaft is opened on the transparent plastic plate below the rotating shaft 4 The end sample via 5 corresponding to the sample via 8. When the rotating shaft sample communication groove 7 is aligned with the lower end of each sample quantitative hole 1, use a common sampler to suck the liquid sample and add the sample from the upper part of a sample quantitative hole 1 in the middle, and the sam...

Embodiment 2

[0026] Such as Figure 4 As shown, a sample reagent rapid filling reactor of the present invention that can be used for dual reagent determination is based on the structure of the sample reagent rapid filling reactor for single reagent determination, in the sample reagent filling device 3 The transparent plastic plate is also provided with multiple-channel reagent quantitative holes 2 with equal spacing corresponding to the sample quantitative holes 1, and the shaft 4 is provided with a shaft reagent through hole 9 correspondingly, and the shaft reagent through hole 9 is connected to the end sample Hole 5 also corresponds.

[0027] When using two reagents to determine biochemical items, first align the sample connecting groove 7 on the rotating shaft 4 with the lower end of each sample quantitative hole 1, and then use a common sampler to absorb a sufficient amount in a sample quantitative hole 1 located in the middle Slowly inject the sample into the sample until each sample qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com