Static state device

An equipment, static technology, applied in the direction of organic insulators, transformer/inductor coils/windings/connections, etc., to achieve the effect of good operation efficiency and low moisture adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

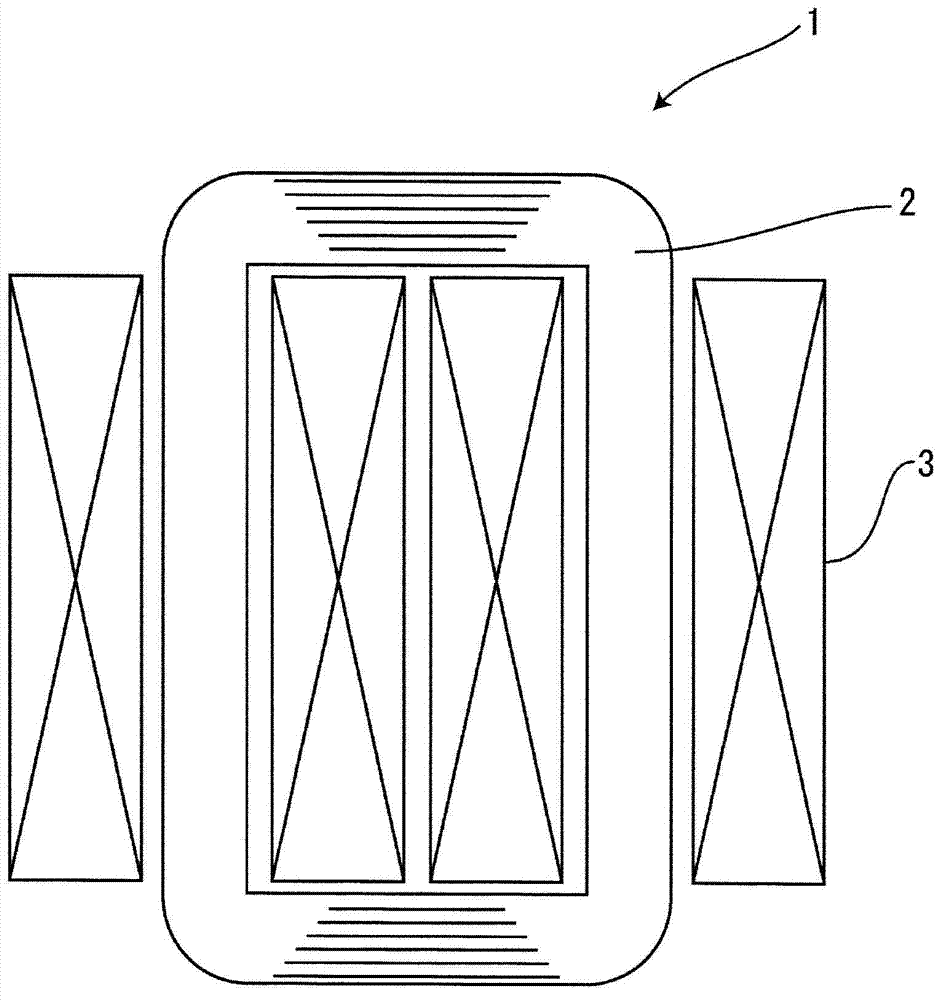

[0033] figure 1 A transformer 1 which is a static device of the present invention is shown, and the transformer 1 is composed of an iron core 2 and a coil 3 . The coil 3 is wound on an iron bobbin described later with a main insulating layer interposed therebetween. Insulating paper made of kraft paper is used for the main insulating layer of the coil 3 of the transformer 1 . Here, a diagram showing a moisture adsorption inhibiting layer provided for the purpose of enhancing the moisture adsorption inhibiting effect of the insulating paper will be described.

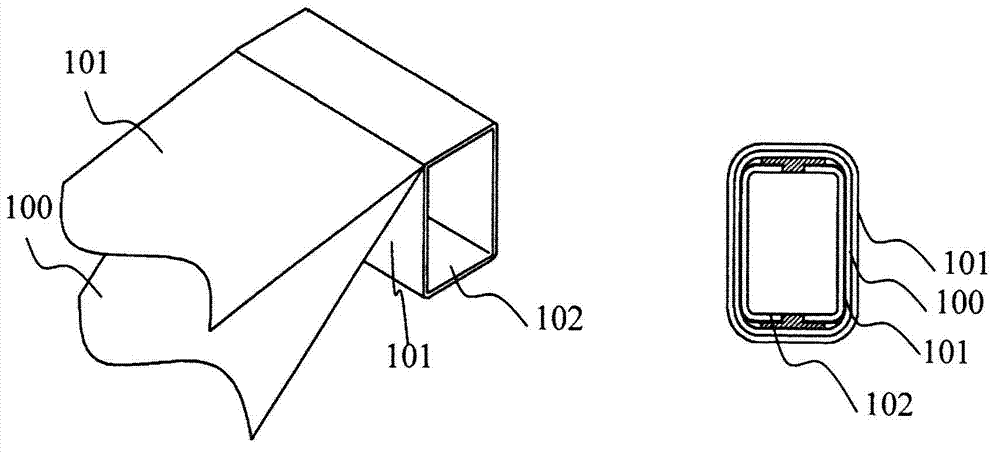

[0034] figure 2 A polymer film 100 constituting a moisture absorption suppressing layer as an insulating material, an insulating paper 101 made of kraft paper as an insulating material, and an iron bobbin 102 for a coil of a static device are shown. The polymer film 100 as the moisture absorption suppression layer is wound on the iron bobbin 102 with insulating paper 101 sandwiched therebetween, and the inner and out...

Embodiment 2

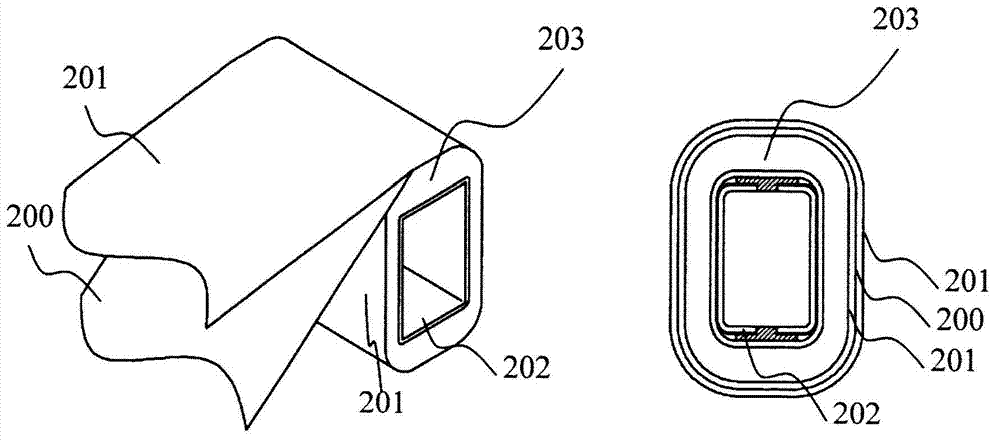

[0036] image 3 A diagram illustrating the provision of a moisture adsorption inhibiting layer on the inner winding of the static device coil of the present invention.

[0037] image 3 Shown is a polymer film 200 constituting a moisture absorption inhibiting layer as an insulating material, an insulating paper 201 made of kraft paper as an insulating material, an iron winding frame 202 of a coil of a static device, and an inner coil wire 203 of the coil. The polymer film 200 serving as a moisture absorption suppressing layer is wound on the inner conductor 203 so as to be sandwiched by the insulating paper 201, and then the outer conductor is wound to complete the coil of the static device. That is, in this embodiment, insulating paper 201 and polymer film 200 having a three-layer structure are interposed between the inner-ring wire and the outer-ring wire.

Embodiment 3

[0039] Figure 4 A diagram illustrating the provision of the moisture adsorption suppression layer on the outermost layer of the static device coil of the present invention.

[0040] Figure 4 Shown is a polymer film 300 constituting a moisture absorption inhibiting layer as an insulating material, an insulating paper 301 made of kraft paper as an insulating material, an iron bobbin 302 of a coil of a static device, and an outer winding 303 of the coil. The polymer film 300 serving as the moisture absorption suppressing layer is wound on the outer winding 303 so as to be sandwiched by the insulating paper 301, and the outer coil wire is wound to complete the coil of the static device. That is, in this embodiment, the insulating paper 301 and the polymer film 300 having a three-layer structure are wound on the outside of the outer coil wire.

[0041] Figure 5 A diagram showing a conventional insulation method for static equipment coils is explained.

[0042] Figure 5 Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com