Method and device for detecting sealing structure of electric heating element of pressurized water reactor nuclear power plant voltage stabilizer

A pressurized water reactor nuclear power plant, electric heating element technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, nuclear power generation, detecting the appearance of fluid at the leakage point, etc., can solve the end plug-outer cladding weld structure Large difference, uncertainty of test results, low leak detection sensitivity, etc., to achieve the effect of eliminating imperfect sealing, saving leaking gas, and uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] A method for testing the sealing structure of an electric heating element of a pressurizer in a pressurized water reactor nuclear power plant includes the following steps:

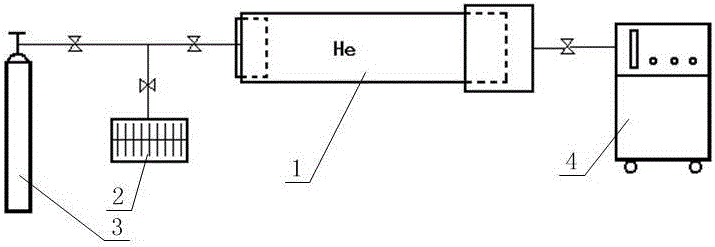

[0052] S1. Use the end plug-outer casing weld helium leak detection device to perform helium leak detection on the end plug-outer casing weld, such as figure 1 shown;

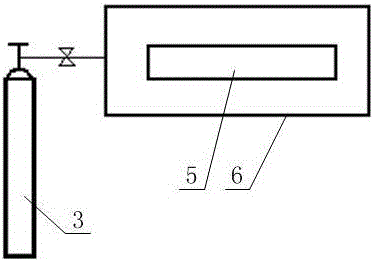

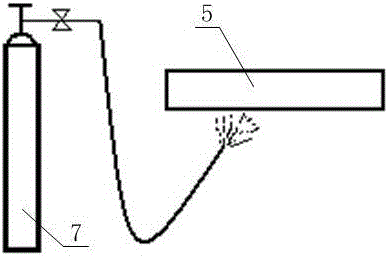

[0053] S2. After the manufacture of the electric heating element 5 is completed, use the integral helium leak detection device to conduct an integral helium leak detection on the product, such as figure 2 , image 3 , Figure 4 shown.

[0054] By using the helium leak detection method to detect the electric heating element of the pressurizer of the pressurized water reactor nuclear power plant, especially the helium leak detection of the end plug-outer casing weld, and then the helium leak detection of the entire electric heating element, to ensure that the The tightness of the detected electric heating element can meet the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com