Dispersed magnetism-conducting block type straight-line switched reluctance motor with single-side stator and rotor with unequal tooth widths

A technology of switched reluctance and magnetic permeable block, which is applied to electric components, electromechanical devices, electrical components, etc., can solve the problems of low utilization rate of iron core materials and low utilization rate of mover slots, and reduce the amount of copper used at the ends. , the effect of simple structure and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

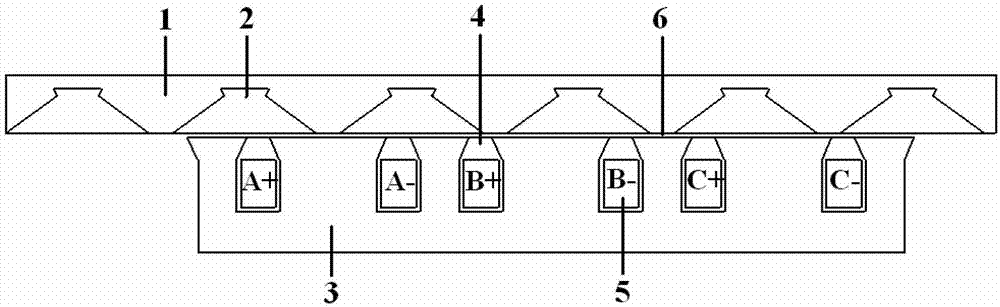

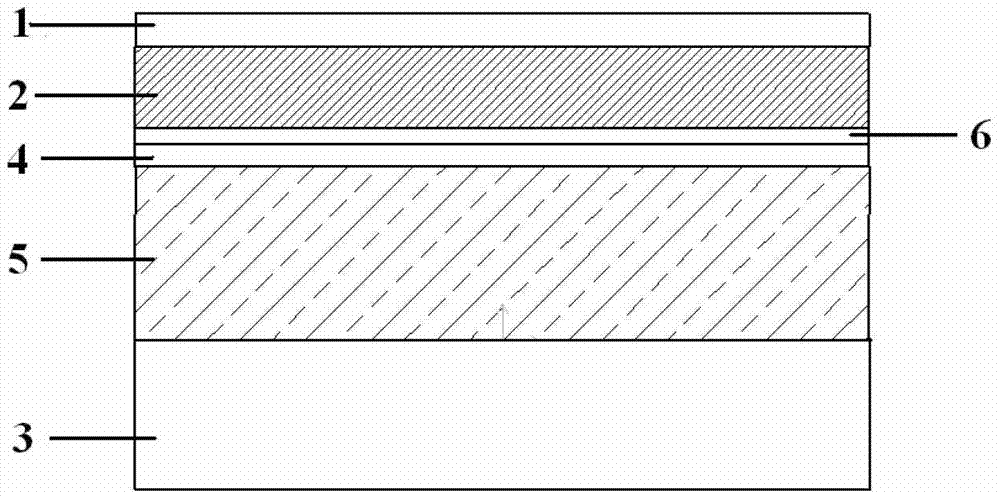

[0027] Such as figure 1 Shown, specific embodiment 1: below in conjunction with figure 1 Embodiment 1 will be described. In this embodiment, the number of phases of the motor is m=3, the number of poles of the mover is Pt=6, and the number of poles of the stator is Ps=4. The blocks 2 are evenly distributed inside the stator frame 1, the bottom of the magnetic permeable block 2 is processed into a dovetail shape so as to be fixed on the stator frame 1, and a mover core 3 is arranged on one side of the stator frame 1, and the stator frame 1 parallel, there is an air gap 6 between the stator base 1 and the mover core 3, the mover core 3 is provided with a mover slot 4, and the mover winding 5 is placed in the mover slot 4, and the mover with a wide tooth width The winding in the mover slot 4 on both sides of the tooth is a coil, and the mover winding 5 enters from the mover slot 4 on one side of the mover tooth with a wider tooth width, passes through the mover slot 4 on the ot...

specific Embodiment approach 2

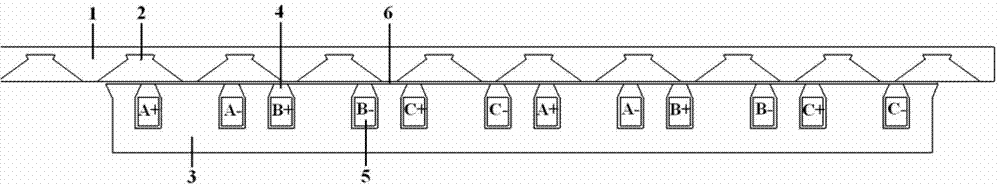

[0028] Specific implementation mode 2: combine below figure 2Embodiment 2 will be described. The difference between Embodiment 2 and Embodiment 1 is that the number of poles of the stator and mover of the motor is different. In this embodiment, the number of phases of the motor is m=3, the number of poles of the mover is Pt=12, and the number of poles of the stator is Ps=8. The blocks 2 are evenly distributed inside the stator frame 1, the bottom of the magnetic permeable block 2 is processed into a dovetail shape so as to be fixed on the stator frame 1, and a mover core 3 is arranged on one side of the stator frame 1, and the stator frame 1 parallel, there is an air gap 6 between the stator base 1 and the mover core 3, the mover core 3 is provided with a mover slot 4, and the mover winding 5 is placed in the mover slot 4, and the mover with a wide tooth width The winding in the mover slot 4 on both sides of the tooth is a coil, and the mover winding 5 enters from the mover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com