Double-motor device on horizontal shaft of photoelectric tracking system and tracking and controlling method under synchronous driving

A photoelectric tracking system and synchronous drive technology, applied in the field of capture and tracking, can solve the problems of affecting the accuracy of the tracking frame shaft system, uneven temperature deformation of the horizontal axis, and lowering the resonance frequency of the horizontal axis, so as to strengthen the system stiffness and improve the response. Bandwidth, improve the effect of controlling bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

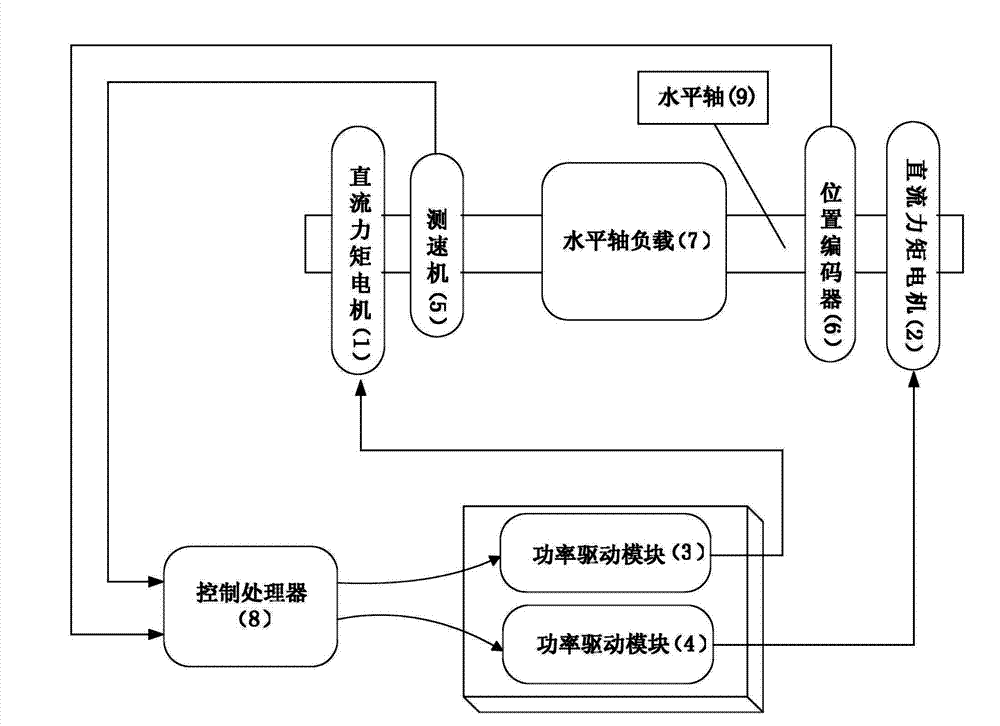

[0027] in figure 1 As shown, the tracking device of the embodiment of the present invention includes: a DC torque motor 1, a DC torque motor 2, a power drive module 3, a power drive module 4, a tachometer 5, a position encoder 6, a horizontal axis load 7 and a control processor 8. ; DC torque motor 1 and tachometer 5 are installed on one side of the horizontal axis; DC torque motor 2 and position encoder 6 are installed on the other side of the horizontal axis; horizontal axis load 7 is installed at the middle position of the horizontal axis, power drive module 3, power The drive module 4 and the control processor 8 are located under the machine.

[0028] in figure 1 As shown, the DC torque motor 1 and the DC torque motor 2 in the real-time example of the present invention are motors of the same model. During installation, since they are installed on both sides of the horizontal axis, the motors must run in the same direction. Therefore, the motor wires of the motors on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com