Adhesive type ceramic PTC (positive temperature coefficient) heater and manufacturing method

A heater and ceramic technology, applied in the direction of the shape of the heating element, can solve the problems of deteriorating the living room environment, etc., and achieve the effect of high heat transfer efficiency and improved heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

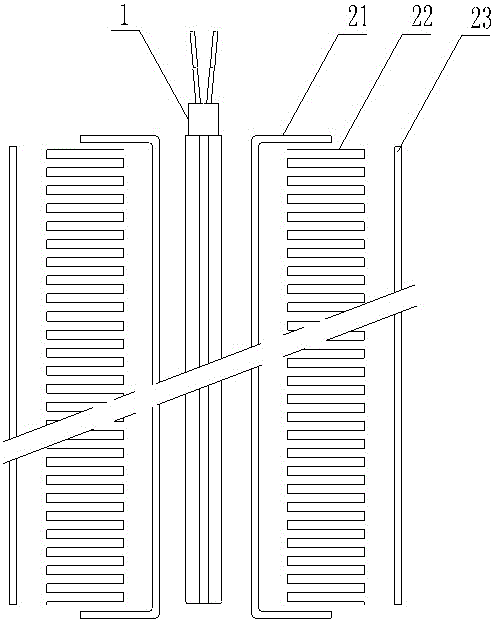

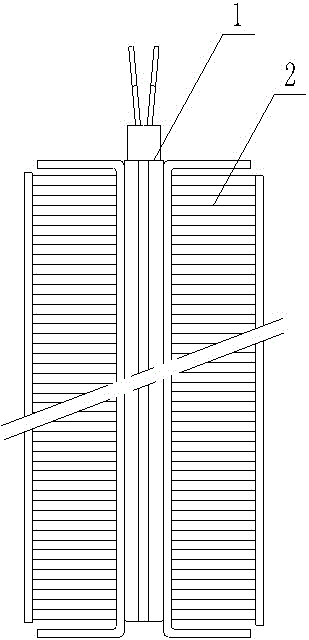

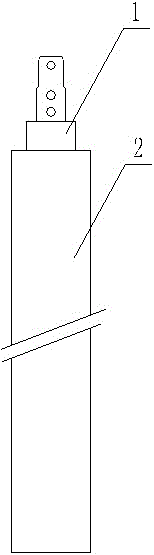

[0030] Such as figure 1 , 2 , 3, the adhesive ceramic PTC heater mainly includes a heating element 1 and a cooling device 2, such as Figure 4 As shown, the heating element 1 includes an aluminum tube 11, a PTC sheet 12, an electrode 13 and an insulating film 14; after the PTC sheets 12 are arranged in a strip array, aluminum powder electrodes are evenly sprayed on both sides of the whole, and the aluminum powder electrodes are The surface is evenly coated with heat-conducting adhesive, and then the electrodes 13 are respectively bonded to the two sides of the PTC sheet 12 through the heat-conducting adhesive, and the contact resistance is 5 ohms; the overall outer surface composed of the PTC sheet 12 and the electrode 13 is coated with heat-conducting adhesive And the whole is wrapped in the insulating film 14; The overall outer surface of the PTC sheet 12, the electrode 13 and the insulating film 14 is coated with a heat-conducting glue and penetrates into the aluminum tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com