LGA and BGA repair process

A kind of process and peaceful technology, applied in the field of microelectronics, can solve the problems of difficult PCB board solder joint overlap, difficult scraper, device blocking, etc., and achieve the effect of improving repair rate, easy operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

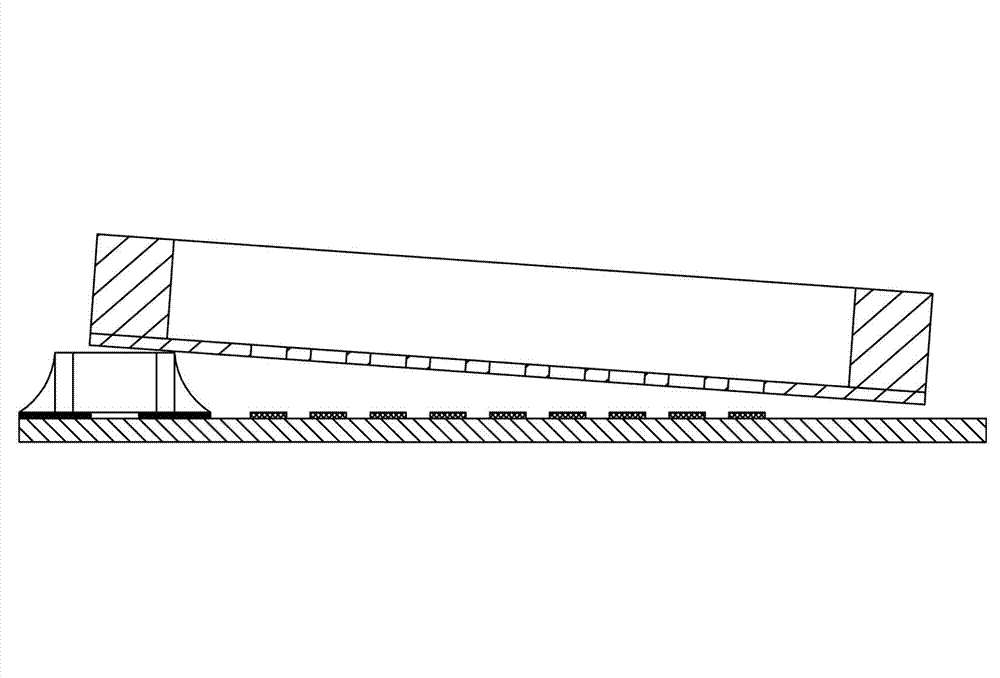

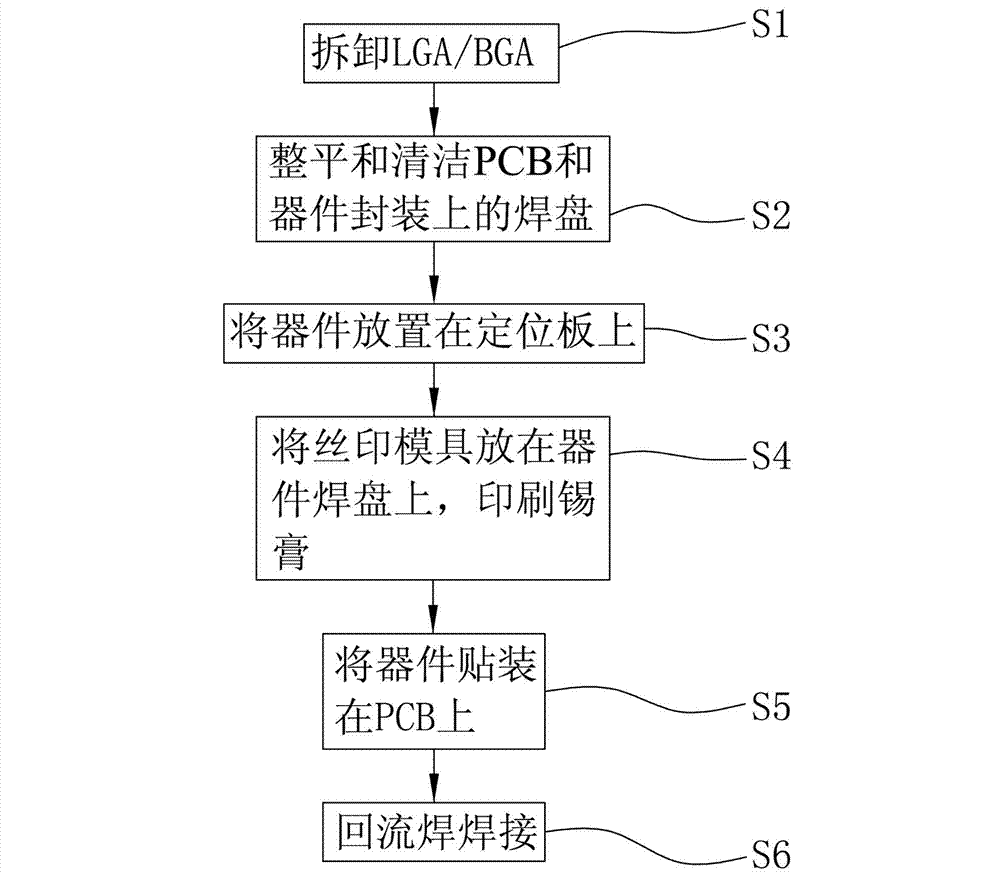

[0021] as attached figure 2 , attached image 3 As shown, the LGA and BGA rework process includes the following steps:

[0022] Step S1, remove the LGA / BGA from the PCB board, use hot air convection or a heating table to heat the device 4 package, when all the solder joints under the device 4 package are melted, use a vacuum nozzle or a Use tweezers to remove the device 4 package from the PCB.

[0023] Step S2, leveling and cleaning the pads on the PCB and the LGA / BGA package. After the device 4 is removed from the PCB, solder remains on the pads of the PCB and device 4. Use a solder suction gun to absorb the hot-melted solder Walk.

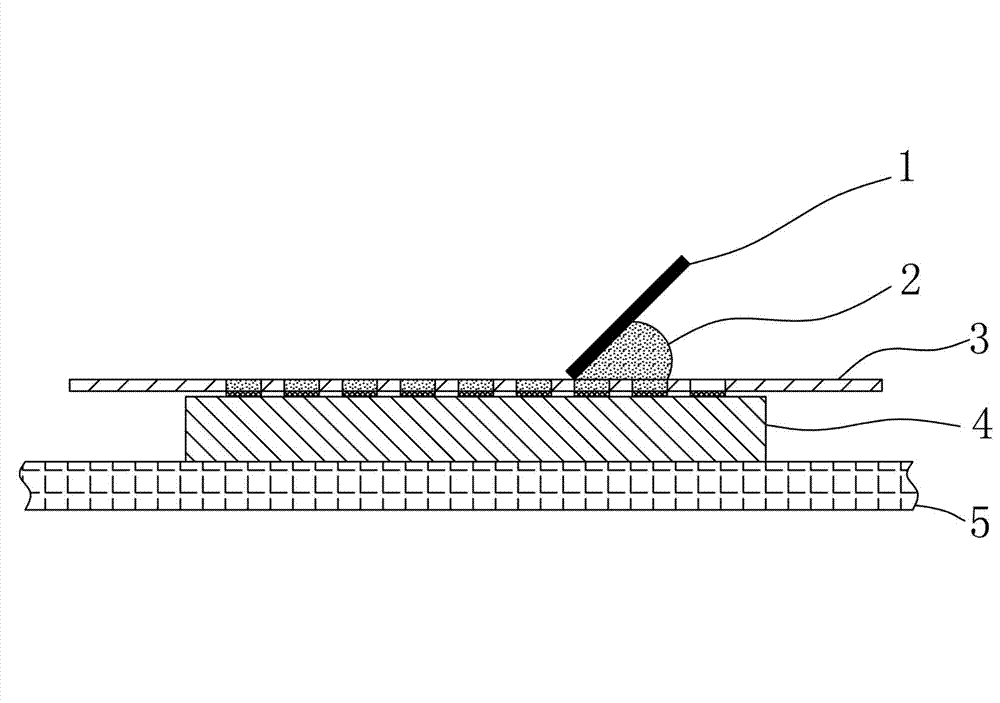

[0024] Step S3, placing the side of the LGA / BGA with solder joints facing up on the positioning plate 5, the positioning plate 5 is a silica gel plate, which has a certain viscosity, and the operator puts the back of the device 4 on the positioning plate 5 , and then lightly press the device 4 to stick the device 4 on the positioning board 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com