Spiral venturi scrubber and wet-method desulphurization and denitration dust-collecting system

A Venturi scrubber, desulfurization and dust removal technology, applied in the field of Venturi scrubber and desulfurization, depinning and dust removal system, can solve the problems of large volume of Venturi scrubber, reduced gas processing efficiency, low gas-liquid separation, etc., to improve removal Efficiency, smooth discharge, and the effect of saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

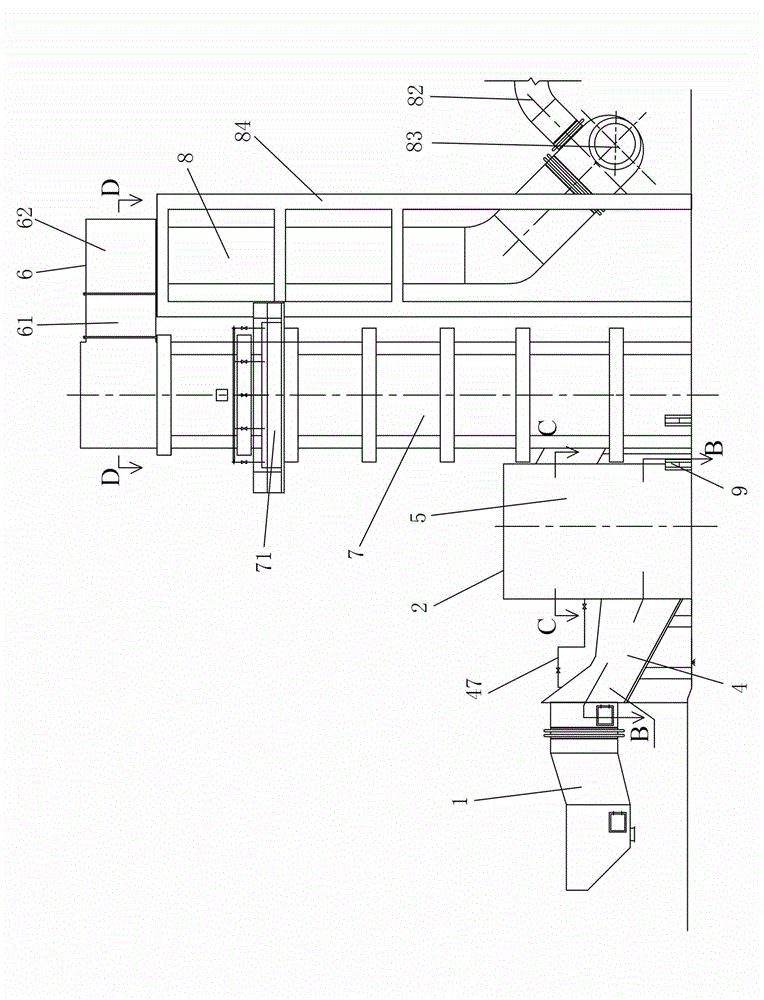

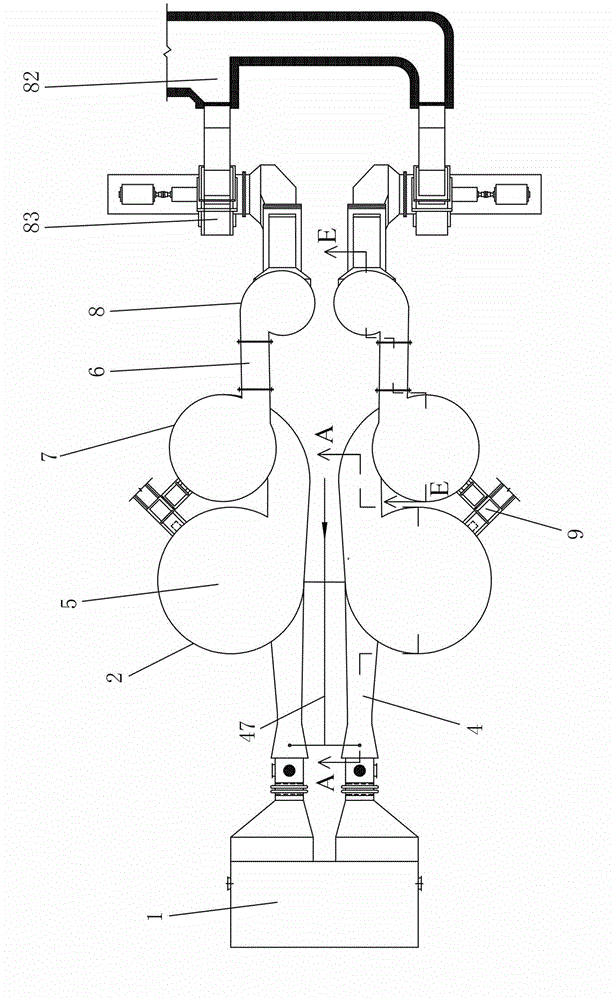

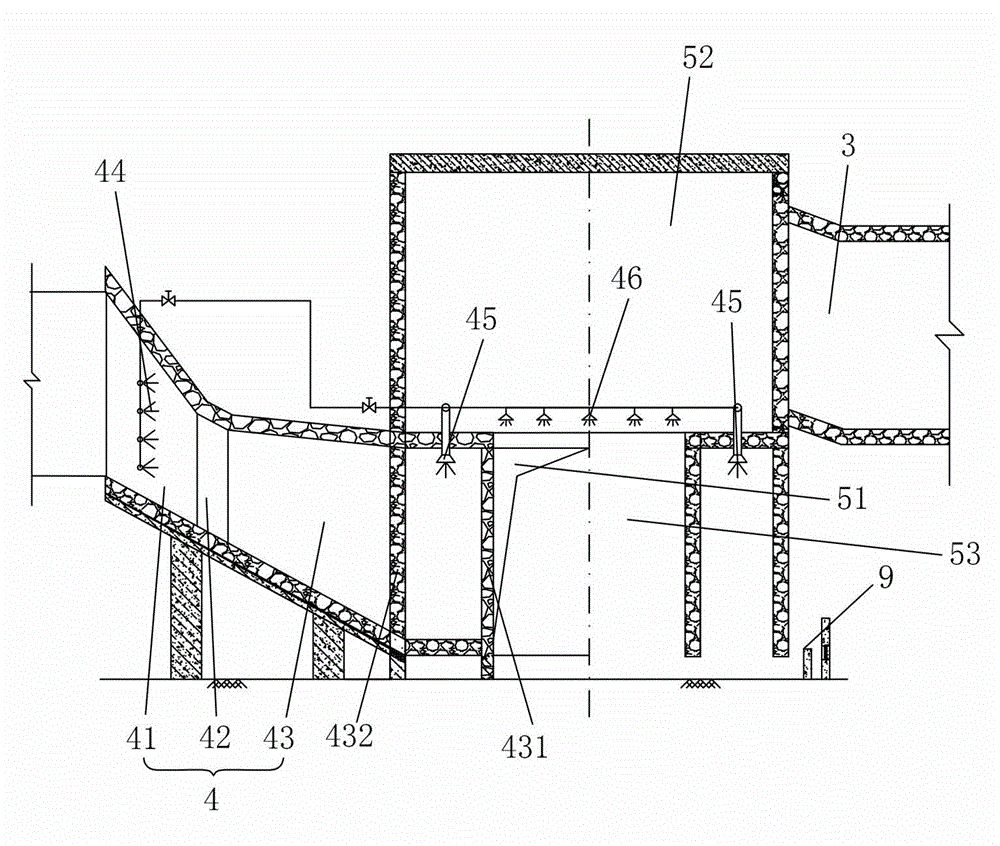

[0028] a kind of like Figure 1 to Figure 5 The spiral Venturi scrubber 2 of the present invention shown in , comprises a Venturi tube 4 and a spiral scrubber 5 (materials are granite), the Venturi tube 4 is horizontal, and the Venturi tube 4 is composed of a shrink tube 41, compressed The throat pipe 42 and the spiral expander 43 are connected in sequence (the spiral expander 43 is horizontal), the first spray washing device 44 is provided inside the shrink tube 41, and the inside of the spiral expander 43 is equipped with The second spray washing device 45 .

[0029] Such as image 3 As shown, the spiral washing tower 5 of this embodiment includes a washing tower body formed by superimposing two upper cylindrical chambers 52 and lower cylindrical chambers 53 with different inner diameters (it can also be approximately regarded as a T-shaped The cylinder is inserted into the center of the spiral expander 43 and superimposed), wherein the outer wall of the lower cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com