A high-salt and high-concentration organic waste liquid treatment process

A technology of organic waste liquid and treatment process, applied in the direction of heating water/sewage treatment, combustion method, lighting and heating equipment, etc., can solve the problems of difficult control conditions, high operating cost, industrialization of high operating cost, etc., to ensure demisting Effect, wide range of application, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

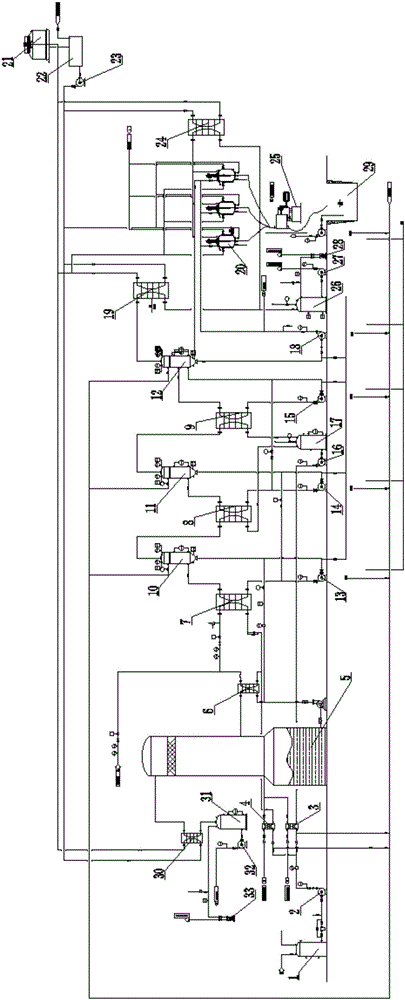

[0030] Further illustrate the present invention below in conjunction with accompanying drawing.

[0031] Such as figure 1 As shown, a high-salt and high-concentration organic waste liquid treatment process is characterized in that it specifically includes the following steps:

[0032] (1) The feed amount of the material is controlled by a frequency converter, and the material is transported from the material buffer tank 1 to the preheater I3 and the preheater II4 through the feed pump 2, and the heat source of the preheater comes from the subsequent three-effect evaporation process The evaporated condensed water of the first-effect heater 7, the second-effect heater 8 and the third-effect heater 9, the preheater I3 and the preheater II4 are all connected with the distillation column 5, and the preheater I3 and the preheater II4 will After the temperature of the material is raised to 90°C, it enters the distillation tower 5 for atmospheric distillation. In the distillation tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com