Method for preparing Al-Ti-C grain refiner

A grain refiner, al-ti-c technology, applied in the field of preparation of Al-Ti-C grain refiner, can solve the poor wettability of graphite and affect the preparation of Al-Ti-C grain refiner and the promotion and use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

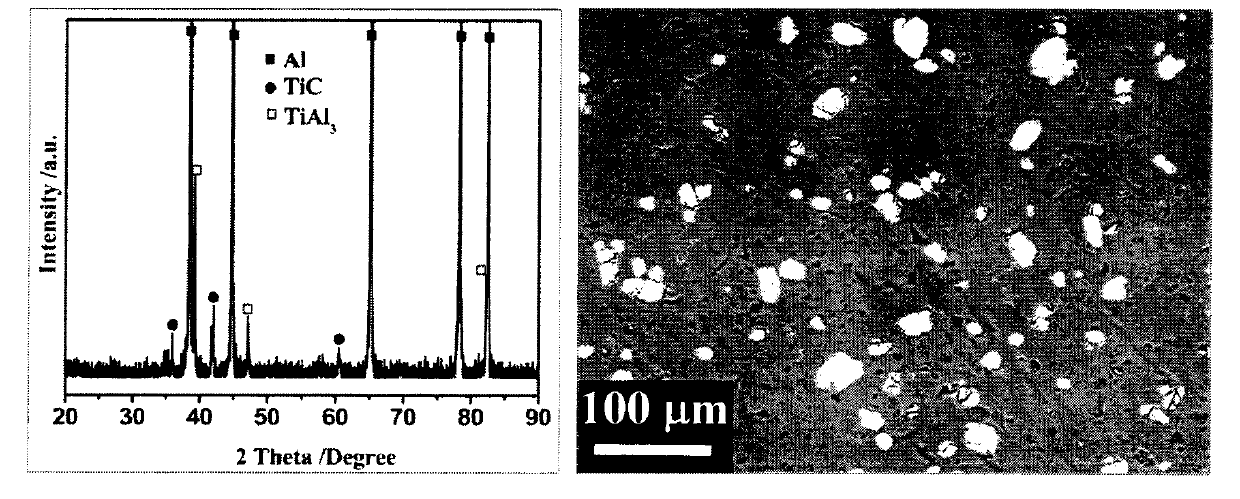

Embodiment 1

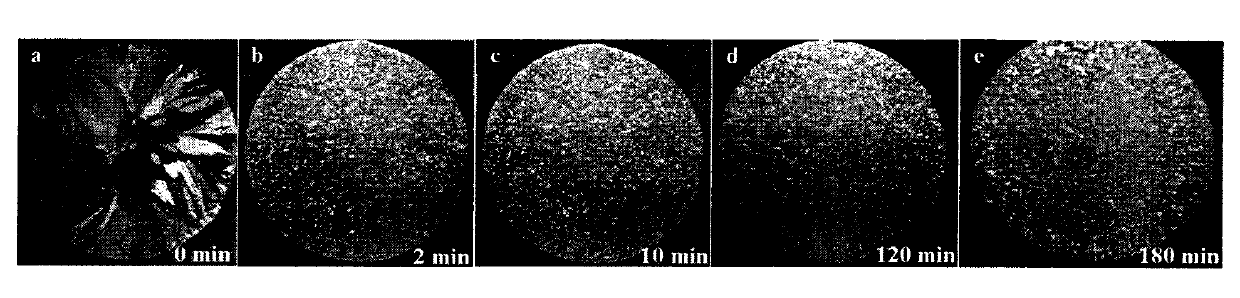

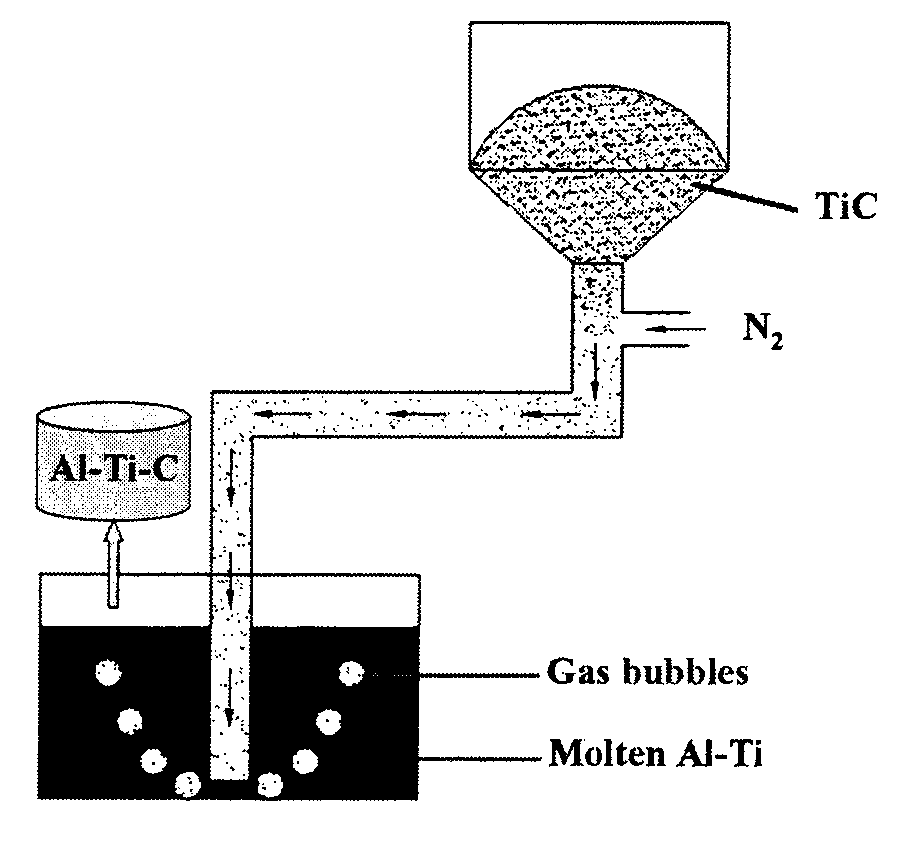

[0015] In the Al-2%Ti alloy, 0.5%, 4.3%, and 8.0% of the mass of TiC (corresponding to the content of C were respectively 0.1%, 0.85%, and 1.6%) were dispersed in it with nitrogen or argon, and added When the temperature is selected 800 ℃, 1100 ℃, 1400 ℃. At 720°C, add 0.2% of the prepared Al-Ti-C grain refiner to 1000g of aluminum melt, heat it for 10min after stirring, pour, corrode, and measure the grain size.

[0016] Table 1 Al-Ti-C grain refiner refinement effect

[0017]

Embodiment 2

[0019] In the Al-6%Ti alloy, 0.5%, 4.3%, and 8.0% of the mass of TiC (corresponding to the content of C were respectively 0.1%, 0.85%, and 1.6%) were dispersed in it with nitrogen or argon, and added When the temperature is selected 800 ℃, 1100 ℃, 1400 ℃. At 720°C, add 0.2% of the prepared Al-Ti-C grain refiner to 1000g of aluminum melt, heat it for 10min after stirring, pour, corrode, and measure the grain size.

[0020] Table 1 Al-Ti-C grain refiner refinement effect

[0021]

Embodiment 3

[0023] In the Al-10%Ti alloy, 0.5%, 4.3%, and 8.0% of the mass of TiC (corresponding to the content of C were respectively 0.1%, 0.85%, and 1.6%) were dispersed in it with nitrogen or argon, and added When the temperature is selected 800 ℃, 1100 ℃, 1400 ℃. At 720°C, add 0.2% of the prepared Al-Ti-C grain refiner to 1000g of aluminum melt, heat it for 10min after stirring, pour, corrode, and measure the grain size.

[0024] Table 1 Al-Ti-C grain refiner refinement effect

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com