Integral forming die for anti-sliding layer on surface of glass reinforced plastic product and production method

A molding mold and FRP technology, which is applied in the field of FRP, can solve the problems of lowering, low anti-skid coefficient, loose and easy falling of quartz sand, etc., and achieve the effect of reducing dust pollution and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

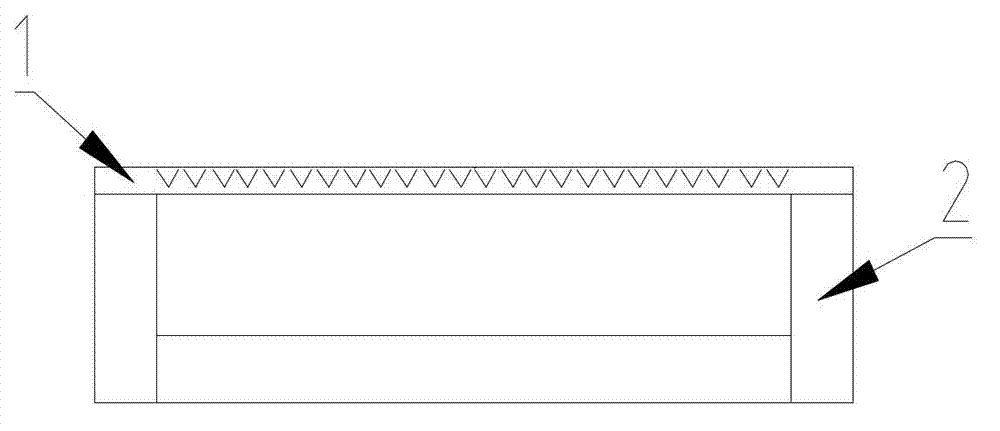

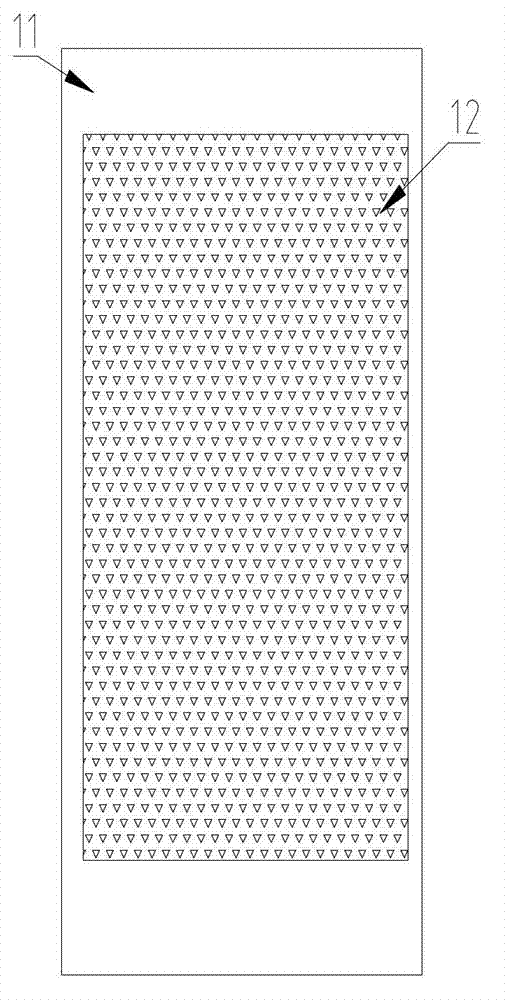

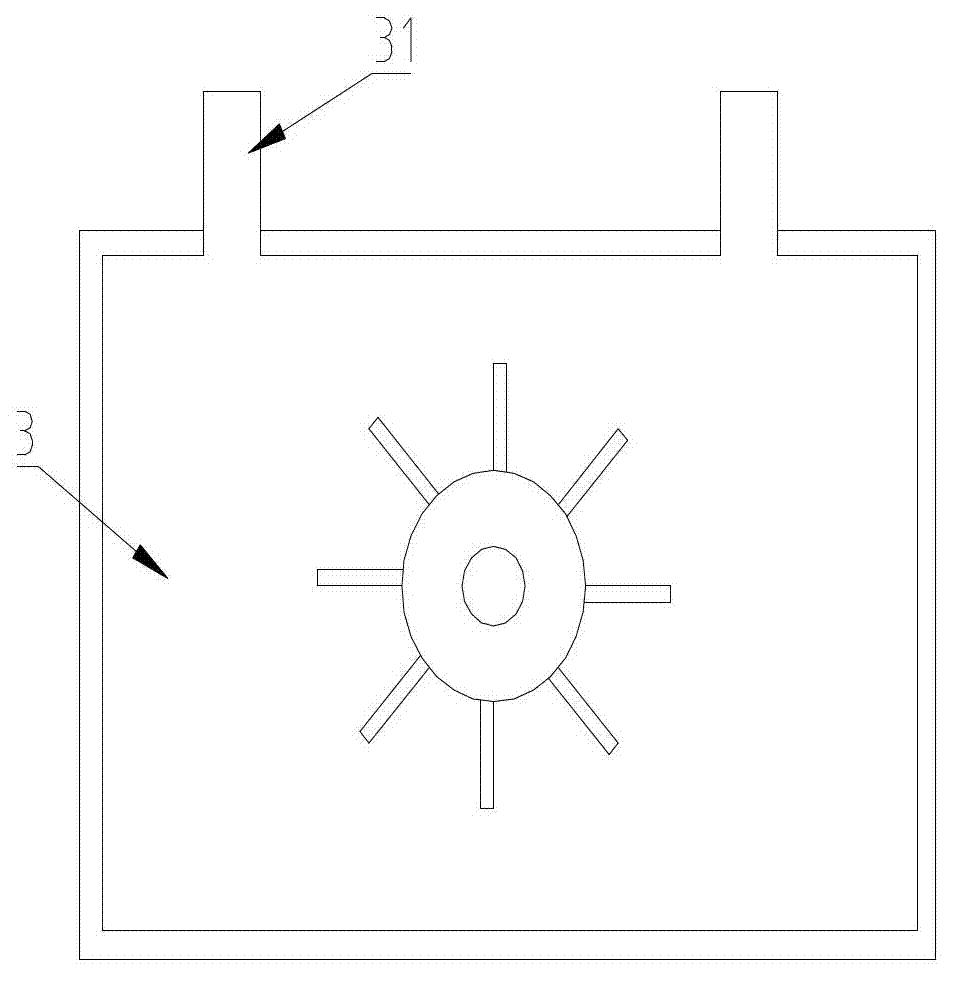

[0022] Such as Figure 1 to Figure 3 As shown, the anti-skid layer integral molding mold on the surface of FRP products of the present invention has a product female mold 1 with concave emery cloth lines, the product female mold is divided into a smooth part 11 and a concave part 12, and the lower part of the female mold is fixed on the female mold support structure 2 on. It also includes a vacuum film, a sealing strip and a vacuum pump control system 3. During the production process, the vacuum film is bonded to the product negative mold 1 through the sealing strip, and the vacuum pump control system 3 is connected to the product negative mold through a rubber pipe 31 supported by a built-in steel wire. Die 1 connection. Through the action of the vacuum pump, the space between the product female mold 1 and the vacuum film reaches a vacuum state, and the resin containing 2% curing agent is introduced into the product female mold 1 with glass fiber by vacuum to realize the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com