Freight train transfinite computer vision inspection system

A technology of computer vision and detection system, applied in the direction of railway vehicle shape measuring device, measuring device, transportation and packaging, etc., can solve problems such as easy omission or false alarm, difficulty in identifying out-of-limit items by sensors, missing detection by optical sensors, etc. To achieve the effect of prolonging the service life, clear picture without jitter, and improving shape data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

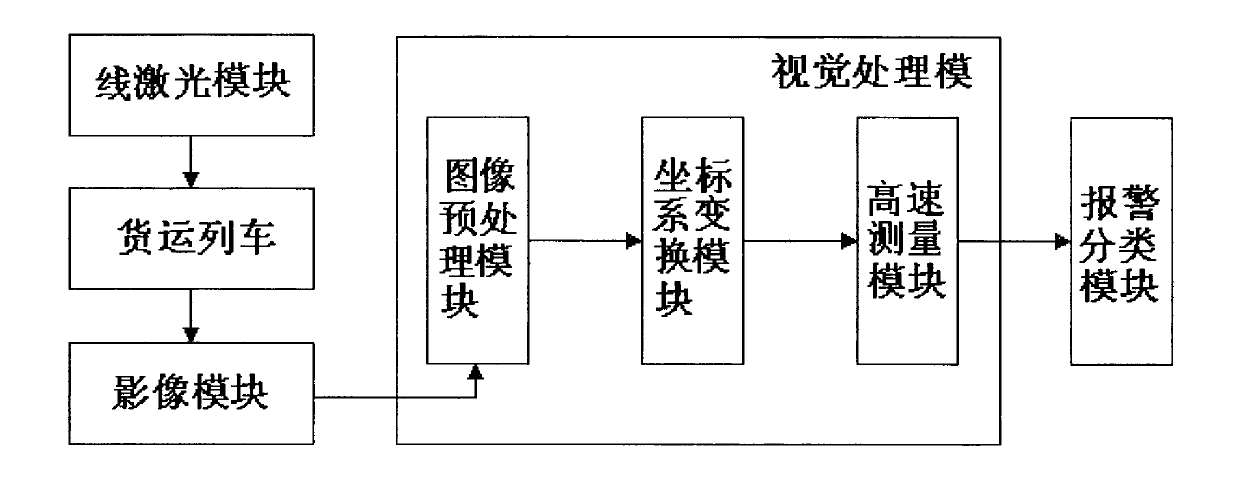

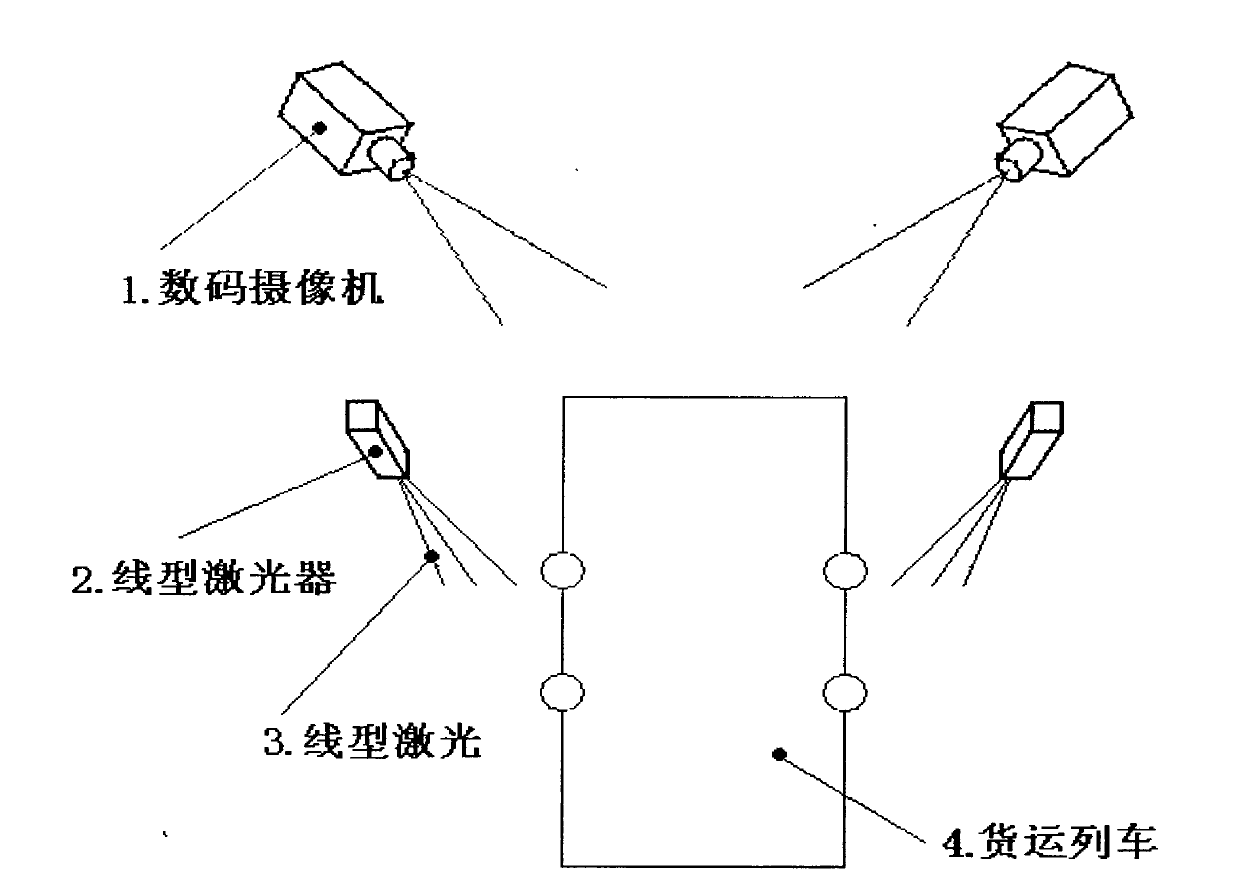

[0020] Such as figure 1 As shown, in the freight train overrunning computer vision detection system of the present invention, the collected information on the top and both sides of the freight car is processed by the image preprocessing module, the coordinate system transformation module, and the high-speed measurement module successively after the image information is input by the camera module. Finally, reliable information is provided to the station managers through the alarm classification module.

[0021] The image preprocessing module refers to: performing image preprocessing such as denoising, thinning, and binarization on the captured laser marking images of the top and both sides of the truck.

[0022] Described coordinate system transformation module refers to: the laser marking image coordinates of the top and both sides of the truck photographed by the camera are converted into cross-sections of real physical space by a space transformation equation (this equation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com