Sensorless speed regulation controller based on observation method and sensorless speed regulation control method for piezoelectric vibration feeder

A speed control controller, piezoelectric vibration technology, applied in the direction of vibrating conveyor, conveyor control device, conveyor, etc., can solve the problem of feeding speed change and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

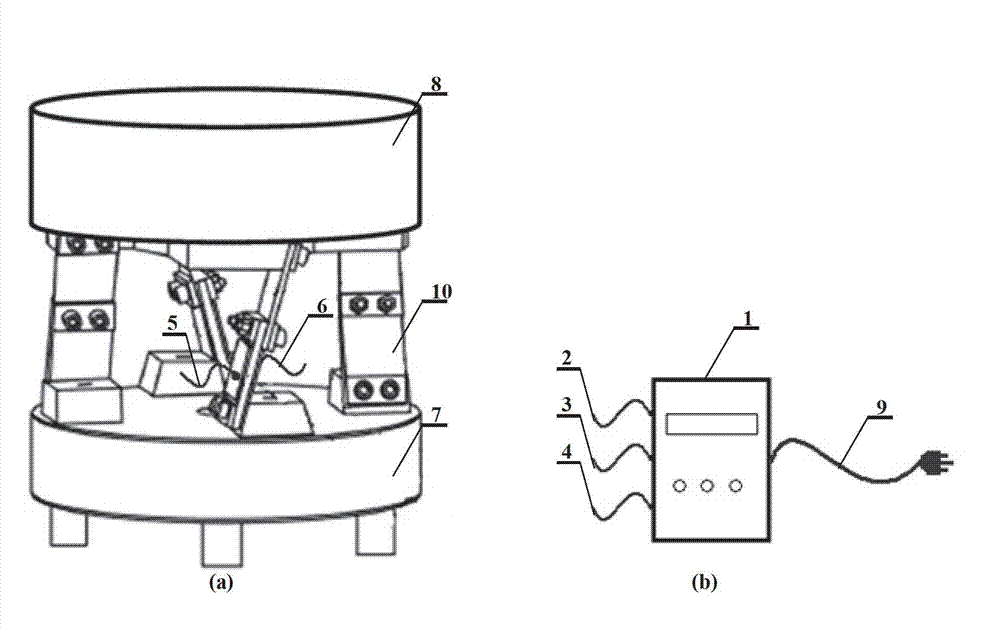

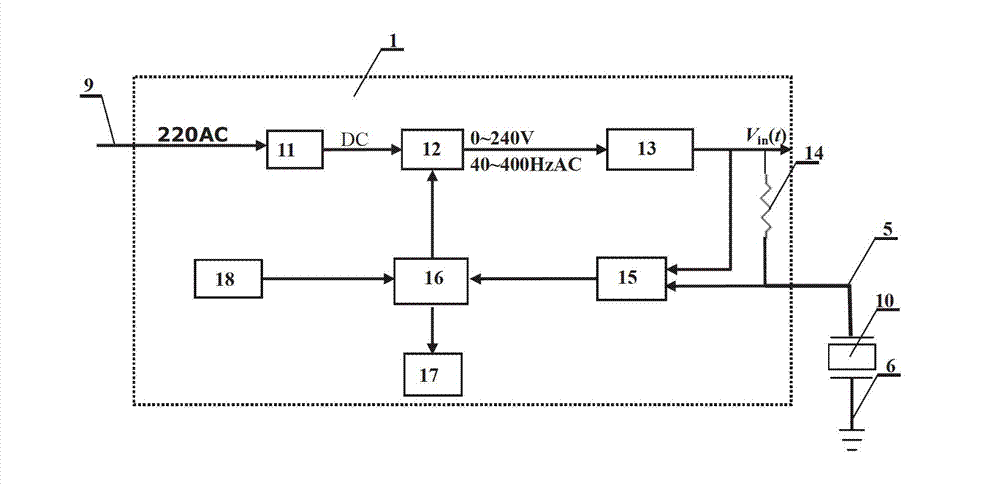

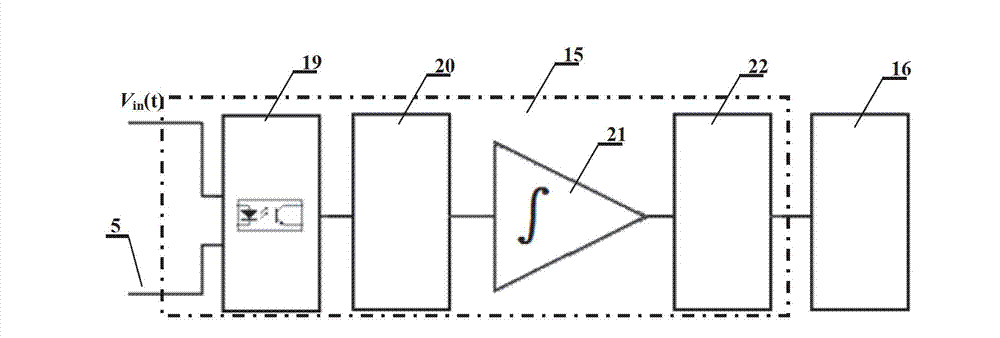

[0048] Embodiment: The theoretical basis of the present invention is that the piezoelectric material has an electromechanical bidirectional reversible piezoelectric effect, and the piezoelectric vibrator is used not only as an exciter to generate vibration, but also as a sensor to feed back vibration velocity information, thereby controlling the feeding speed. Piezoelectric vibrating feeder and sensorless speed controller are attached figure 1 As shown, the piezoelectric vibrators on the four vibrating arms in the piezoelectric vibrating feeder are connected in parallel, which are collectively referred to as piezoelectric vibrators 10. The positive terminal 2 of the driving voltage is connected to the piezoelectric electrode A 5, and the negative terminal 3 of the driving voltage is connected. Connect with the piezoelectric electrode B 6, connect the ground wire 4 with the feeder base 7, insert the mains power line 9 into the 220V / 50Hz mains socket, set the feeding speed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com