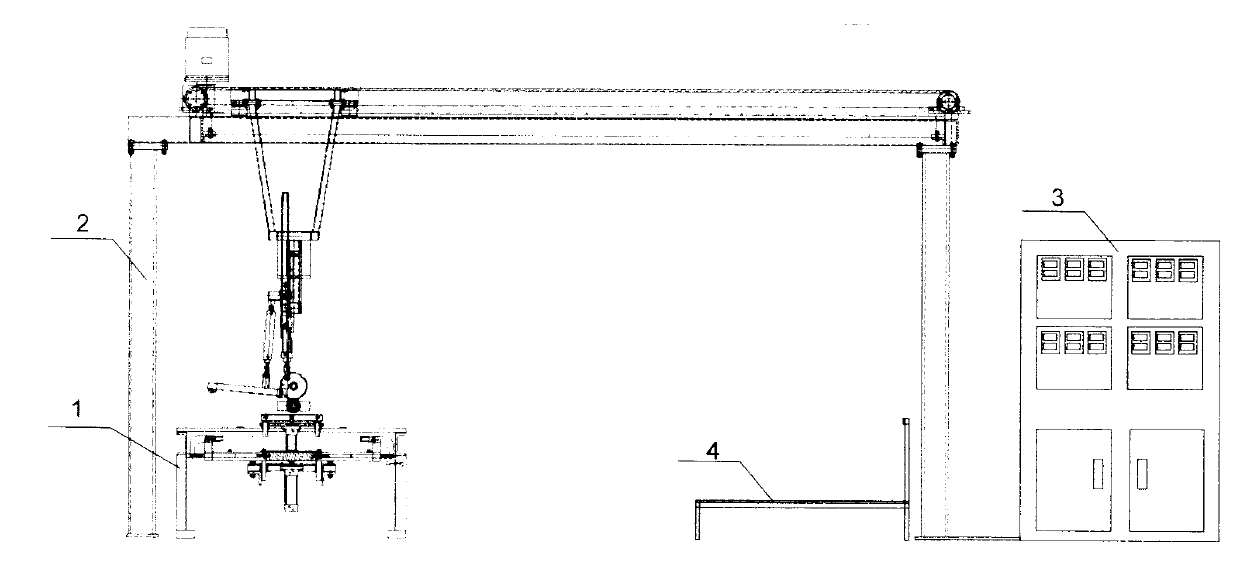

Automatic brick picking machine and working principle of automatic brick picking machine

A brick machine and automatic technology, applied in the field of automatic brick picking machines, can solve the problems of high labor cost, low work efficiency, fatigue, etc., and achieve the effect of reducing labor cost and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

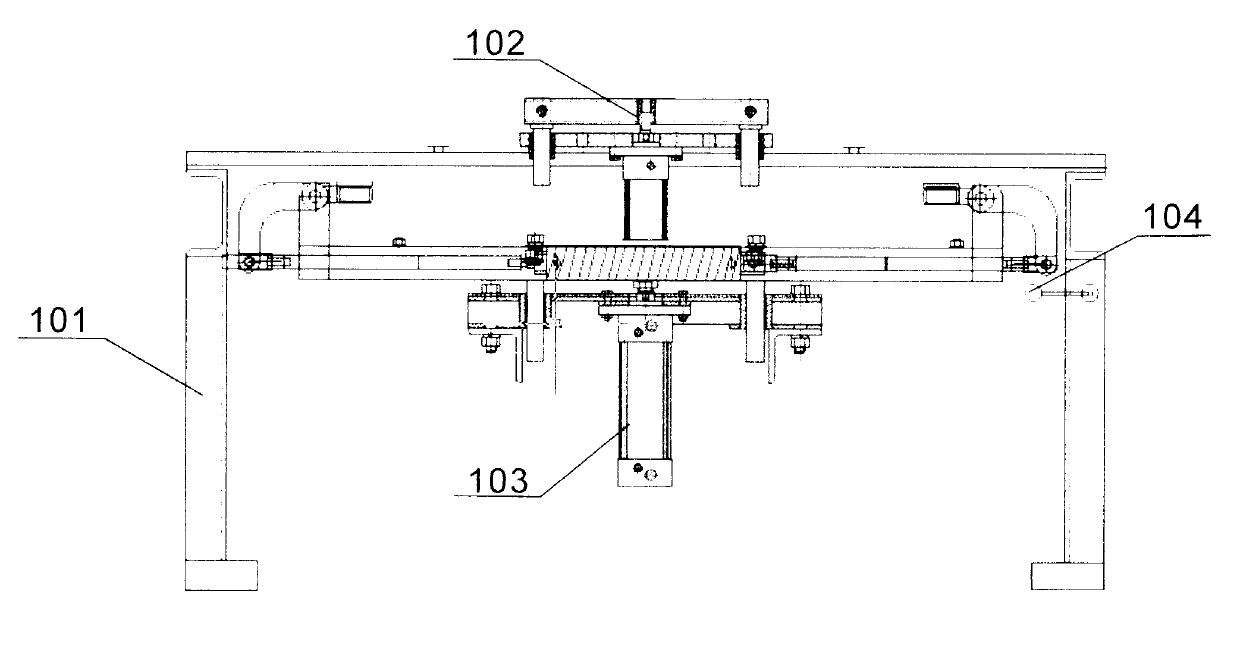

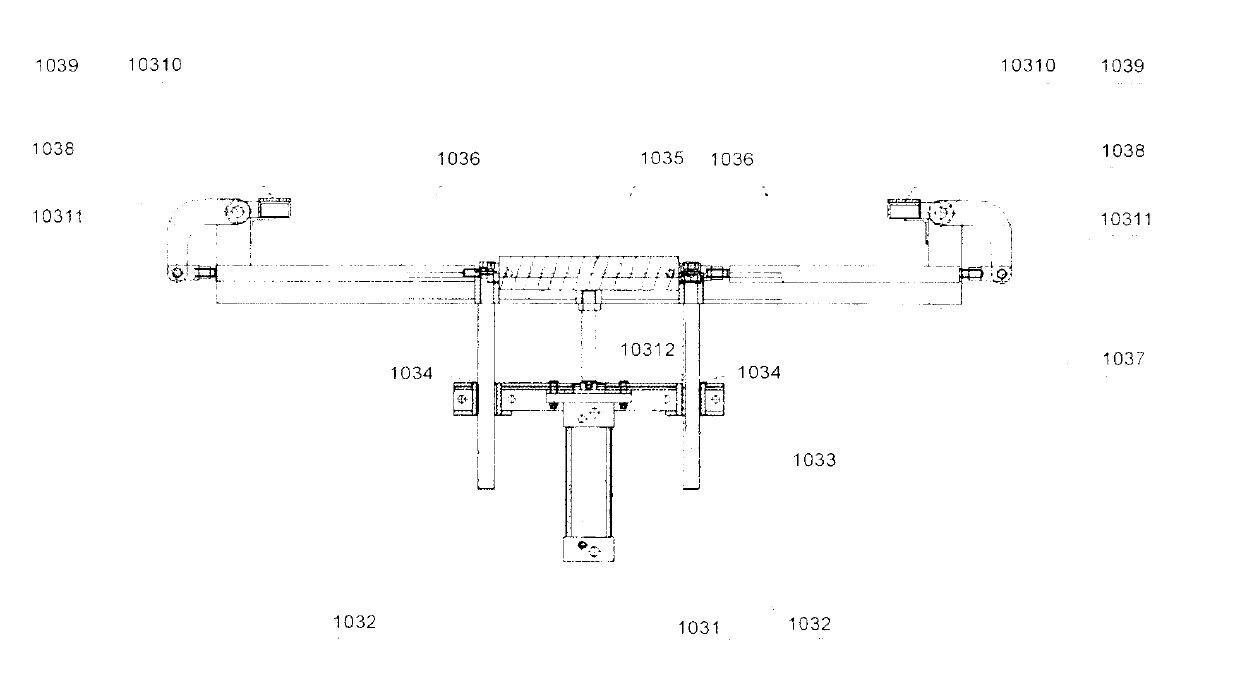

[0026] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

[0027] See attached Figure 1-5 , when the tile passes the position of the sensor 104 on the production line control frame 1, the control system 3 obtains the signal of the sensor 104, the control system 3 opens the brick jacking device 102 to start working, and the jacking cylinder 1031 jacks up the bracket 1037, and the bracket 1037 The supporting plate 1038 just lifts the tiles. At this time, the tiles can continue to pass in the space at both ends of the support 1037. When the lifted tiles are removed, the stretching cylinder 1035 drives the supporting plates on both sides of the support 1037 through the connecting rods 1036 on both sides. 1038 is stretched outwards and opened (the ceramic tiles of the production line can be guaranteed to continue to pass between the supporting plates on the two ends of the bracket). The supporting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com