Electro-hydraulic integrated driver for rotary pin of container hanging tool

A container spreader and integrated technology, applied in the field of machinery, can solve problems such as hydraulic leakage and motor burnout, and achieve the effects of easy maintenance, high overload resistance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

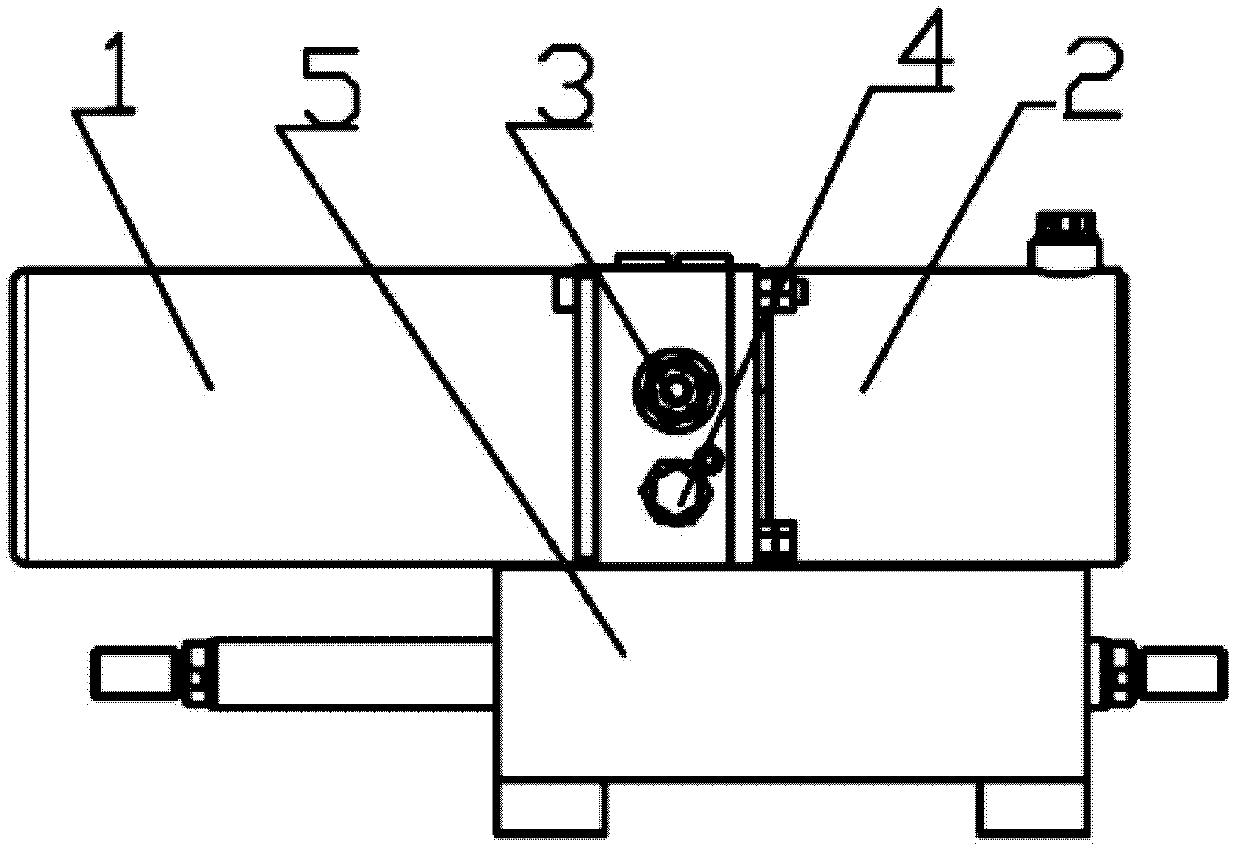

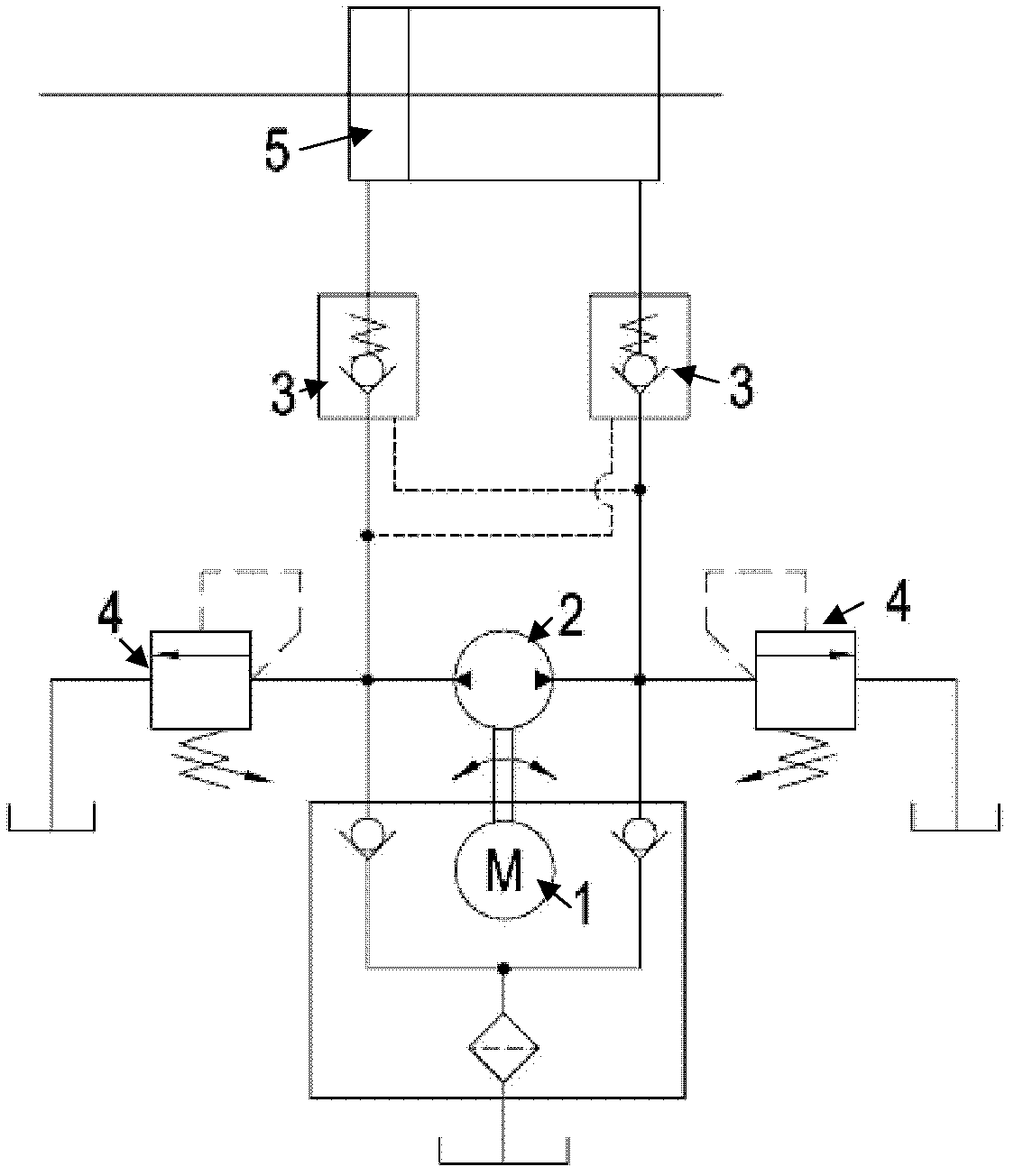

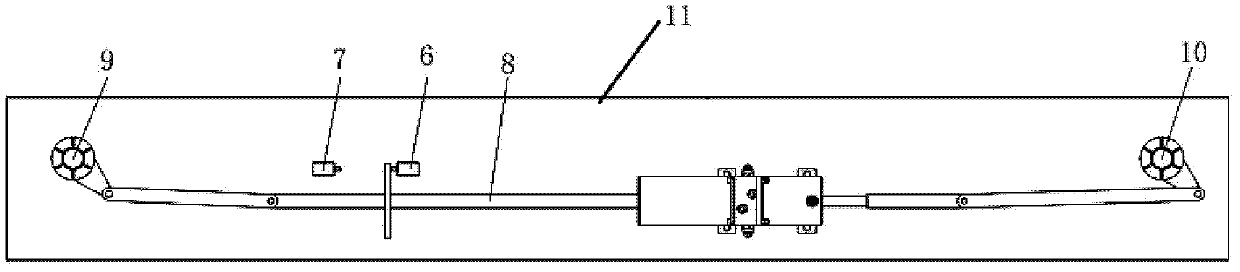

[0022] Such as figure 1 , figure 2 and image 3 As shown, an electro-hydraulic integrated driver for container spreader repinning according to the present invention includes a bidirectional motor 1, a bidirectional hydraulic pump 2, two overflow valves 4, a bidirectional hydraulic cylinder 5, a left A hydraulic control check valve 3 and a right hydraulic control check valve 3, the two-way hydraulic pump 2 has a left hydraulic outlet and a right hydraulic outlet, and the two-way hydraulic cylinder 5 has a left hydraulic channel and a right side hydraulic channel, the two-way hydraulic cylinder 5 has a piston rod, and the left side hydraulic control check valve 3 and the right side hydraulic control check valve 3 each have a control port, wherein the two-way motor 1 The output shaft of the two-way hydraulic pump 2 is connected with the input shaft of the two-way hydraulic pump 2, the left hydraulic outlet of the two-way hydraulic pump 2 is connected with the left hydraulic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com