Double-end sealing device for electrodeless lamps

An electrodeless lamp, double-ended technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems affecting personal safety, unbalanced force, fracture, etc., to reduce operational technical difficulty, heating Uniform fusion, reducing the effect of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

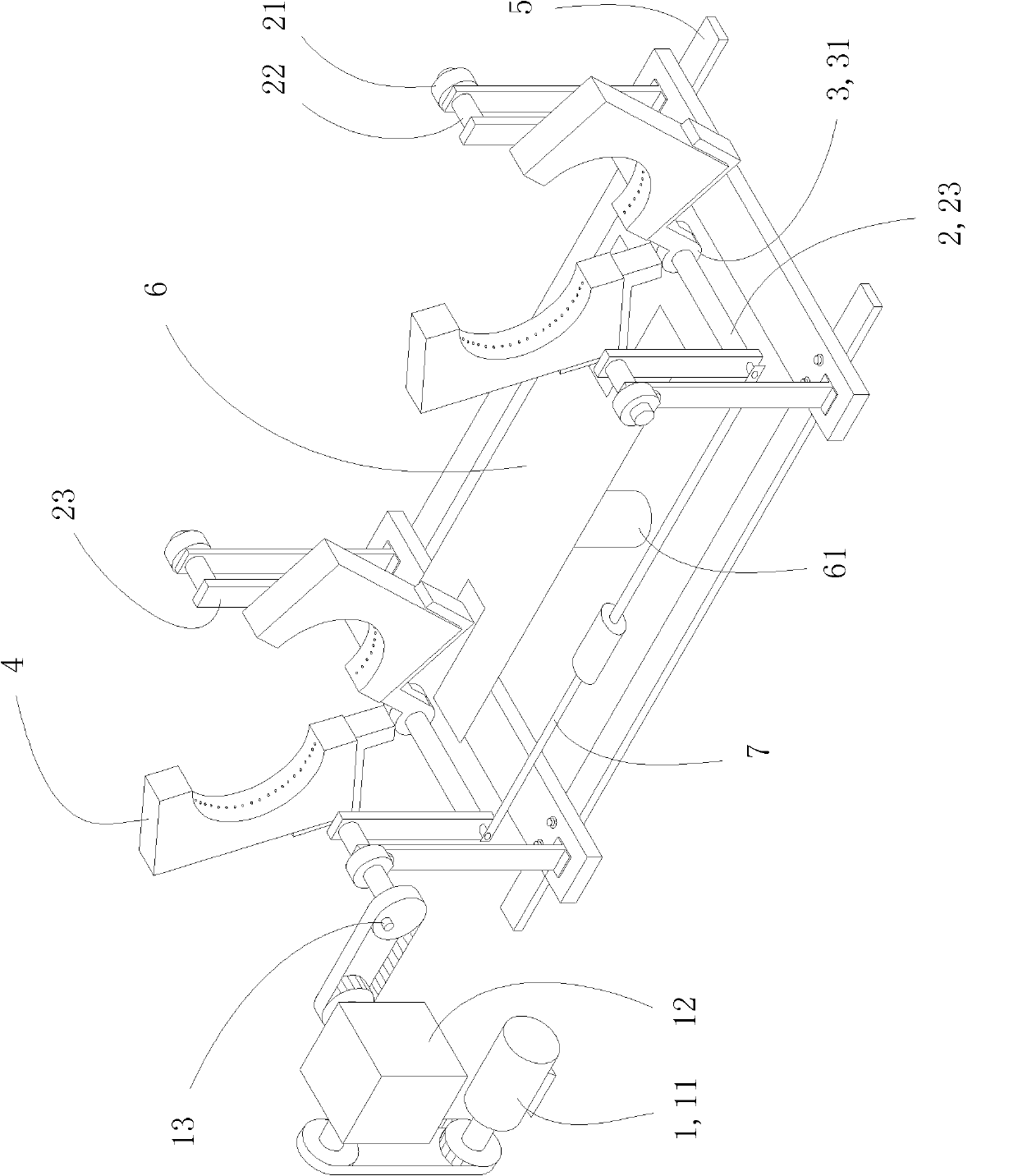

[0019] combine figure 1 , the present invention has a drive device 1, a transmission device 2, a control block 3 and an annular fire head 4; the drive device 1 is composed of a servo motor 11, a reducer 12 and a position sensing device 13, the position sensing device 13 is an infrared sensing device, and the ring fire head 4 It is two open fire heads, two ring fire heads 4 are arranged on the same plane, the rotation axes of the two ring fire heads 4 are parallel, the lower end of the ring fire head 4 is provided with a control block 3, and the transmission device 2 has bearing frames arranged on both sides of the ring fire head 4 21. There are two bearing frames 21 on each side, respectively corresponding to the annular fire head 4, and a rotating shaft 22 is installed on each bearing frame 21, and the rotating shaft 22 is coaxially arranged with the corresponding ring fire head 4, and the rotating shaft 22 is fixedly connected to the swing crank arm 23. The other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com