Method for separating and purifying nevirapine

A technology of nevirapine and organic solvents, which is applied in the field of drug synthesis, can solve the problems of low purity and low yield of nevirapine crystalline products, and achieve the effects of stable product quality and yield, simple and controllable process, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

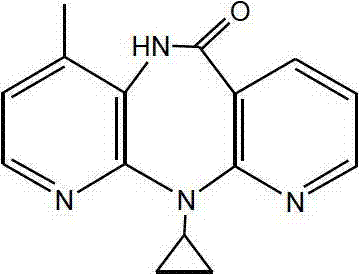

Image

Examples

Embodiment 1

[0029] Add 1868g of 95% ethanol and 4.7g of medicinal activated carbon to 142g of nevirapine crude product (93.4g on dry weight, 94% purity), raise the temperature to 65°C, keep it for 1.5 hours, suction filter while it is hot, and use 177g of hot 95% ethanol Wash the filter cake, then concentrate 1400g of ethanol at 40°C and a vacuum of -0.05MPa, then slowly cool down to a system temperature of 5°C at a rate of 15°C / hr, keep it warm for 2 hours, and filter with suction to obtain 118g of a yellow solid, namely Nevirapine primary crystallization material; add 1291.0g 95% ethanol and 2.9g medicinal activated carbon to the obtained 115g nevirapine primary crystallization material (dry weight: 85.1g, purity: 98.5%), heat up to 65°C for secondary crystallization process, keep warm For 1.5 hours, suction filter while it is hot, and wash the filter cake with 210g of hot 95% ethanol, then concentrate 890g of ethanol at 40°C and a vacuum of -0.05MPa, and then slowly cool down at a rate ...

Embodiment 2

[0031] Add 3100g of 95% ethanol and 7.0g of medicinal activated carbon to 210g of nevirapine crude product (dry weight 140g), raise the temperature to 71°C, keep it for 2 hours, suction filter while it is hot, and wash the filter cake with 286g of hot 95% ethanol, and then Concentrate 2536g of ethanol under the condition of 50°C and a vacuum of -0.06MPa, then slowly cool down to a system temperature of 8°C at a rate of 10°C / hr, keep it warm for 12h, and obtain 183g of yellow solid by suction filtration, which is the primary crystallization material of nevirapine; Add 2210g of 95% ethanol and 4.2g of medicinal activated carbon to the obtained 180g of nevirapine primary crystallization material (dry weight 123g), heat up to 75°C to dissolve and carry out the secondary crystallization process, keep it warm for 2 hours, suction filter while it is hot, and use 250g of hot 95 Wash the filter cake with % ethanol, then concentrate 1405g of ethanol at 50°C and a vacuum of -0.05MPa, then...

Embodiment 3

[0033]Add 5950g of 5% ethanol and 10g of medicinal activated carbon to 350g of nevirapine crude product (dry weight 238g), raise the temperature to 80°C, keep for 3 hours, suction filter while it is hot, and wash the filter cake with 450g of hot 95% ethanol. ℃, vacuum degree is -0.06MPa under the condition of concentrating ethanol 4750g, then slowly cool down to the system temperature of 12 ℃ at a rate of 18 ℃ / hr, keep warm for 7h, and obtain 285g yellow solid by suction filtration, which is nevirapine primary crystallization material; Add 4160g of 95% ethanol and 7.1g of medicinal activated carbon to the primary crystallization material of 280g of nevirapine (dry weight: 208g), raise the temperature to 80°C for the secondary crystallization process, keep it warm for 3 hours, suction filter while it is hot, and wash with 600g of hot 95% ethanol The filter cake was then concentrated to 3160g of ethanol at 65°C and a vacuum of -0.08MPa, and then slowly cooled to a system temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com