Polytetrafluoroethylene (PTFE) plate activating device and method thereof

A technology for activation treatment and activation of water, which is applied in the field of fluoroplastic surface activation treatment devices, which can solve the problems of harming the health of operators, polluting the surrounding environment, and long activation time, and achieves good activation quality, high degree of automation, and convenient and quick preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

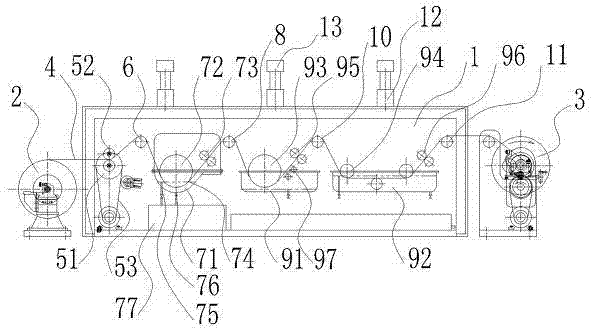

[0027] Such as figure 1Shown, a kind of PTFE plate activation treatment device of the present invention comprises the activation treatment chamber 1 of an airtight cuboid shape, has three exhaust outlets 12 along the lengthwise direction at the top of activation treatment chamber 1, three exhaust outlets 12 Evenly distributed on the top surface of the activation treatment chamber 1, a steam-water series jet vacuum pump 13 is respectively connected on the exhaust port 12, and an unwinding roller 2 is installed in parallel on the outside left side of the activation treatment chamber 1 in the length direction, and a parallel installation is installed on the right side The winding roller 3, the central plane of the unwinding roller 2 and the winding roller 3 are coplanar with the central plane of the longitudinal direction of the activation treatment chamber 1, and a constant speed is arranged in sequence from left to right in the longitudinal direction of the activation treatment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap