Method and device for refining liquid paraffin

A liquid paraffin and refining method technology, applied in the refining of petroleum wax and other directions, can solve the problems of low impurity removal rate, violation of environmental protection and low carbon, affecting product quality, etc., and achieve the effects of improving product quality, low cost, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The refining method of liquefied paraffin in this embodiment is divided into the following steps:

[0025] 1. Pass the 45°C liquid paraffin raw material into the liquid paraffin purifier from the oil inlet, and simultaneously pass 40°C hydrochloric acid into the liquid paraffin purifier from the acid inlet, and the liquid paraffin raw material and the hydrochloric acid are fully contacted through the mixing device;

[0026] 2. After the two liquids are fully contacted, the liquid paraffin floats upward naturally and is discharged from the oil outlet to obtain refined liquid paraffin; the water in the liquid paraffin raw material settles down with hydrochloric acid and is discharged from the acid outlet; at the same time, the solid in the mixed liquid Impurities naturally sink to the bottom and are regularly discharged from the slag outlet.

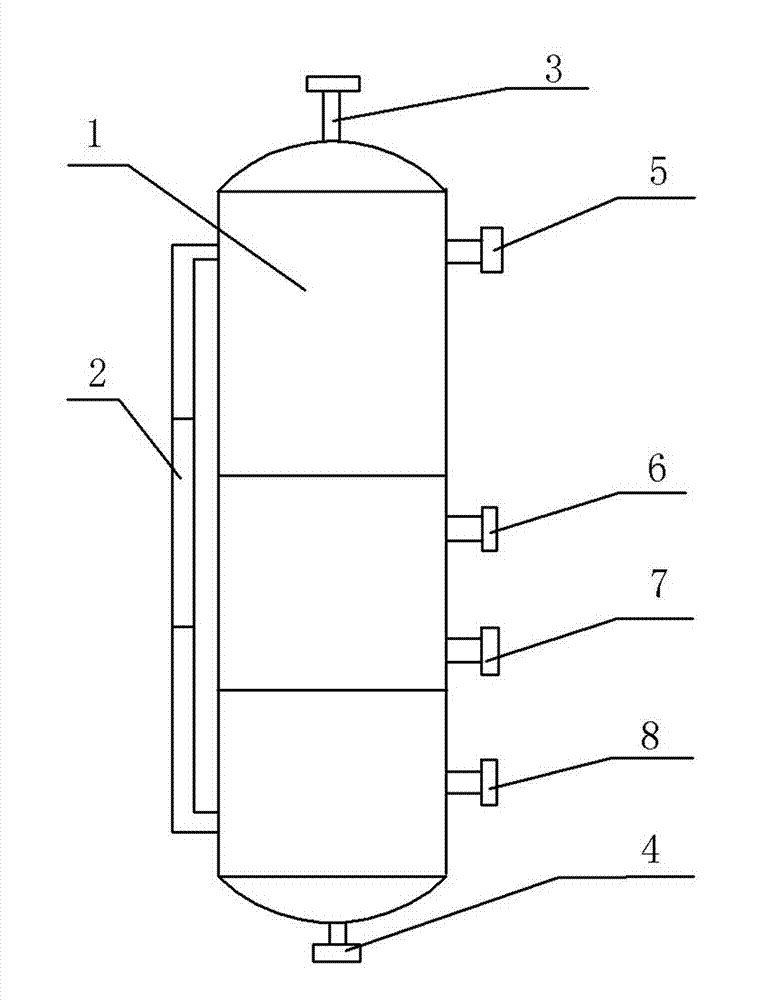

[0027] Such as figure 1 The liquefied paraffin purifier used in the liquid paraffin refining method of the present embodiment sh...

Embodiment 2

[0029] The refining method of liquefied paraffin in this embodiment is divided into the following steps:

[0030] 1. Pass the 50°C liquid paraffin raw material into the liquid paraffin purifier from the oil inlet, and simultaneously pass 45°C hydrochloric acid into the liquid paraffin purifier from the acid inlet, and the liquid paraffin raw material and the hydrochloric acid are fully contacted through the mixing device;

[0031] 2. After the two liquids are fully contacted, the liquid paraffin floats upward naturally and is discharged from the oil outlet to obtain refined liquid paraffin; the water in the liquid paraffin raw material settles down with hydrochloric acid and is discharged from the acid outlet; at the same time, the solid in the mixed liquid Impurities naturally sink to the bottom and are regularly discharged from the slag outlet.

[0032] Such as figure 1 The liquefied paraffin purifier used in the liquid paraffin refining method of the present embodiment sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com