Electrode distance adjustable type microarc oxidation electrode holder

A micro-arc oxidation and electrode fixture technology, applied in anodizing, electrolysis process, electrolysis components, etc., can solve the problems of inability to replace the cathode structure at any time, unable to adjust the distance between cathode and anode electrodes, complexity, etc., to improve current efficiency and simple structure. , the effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

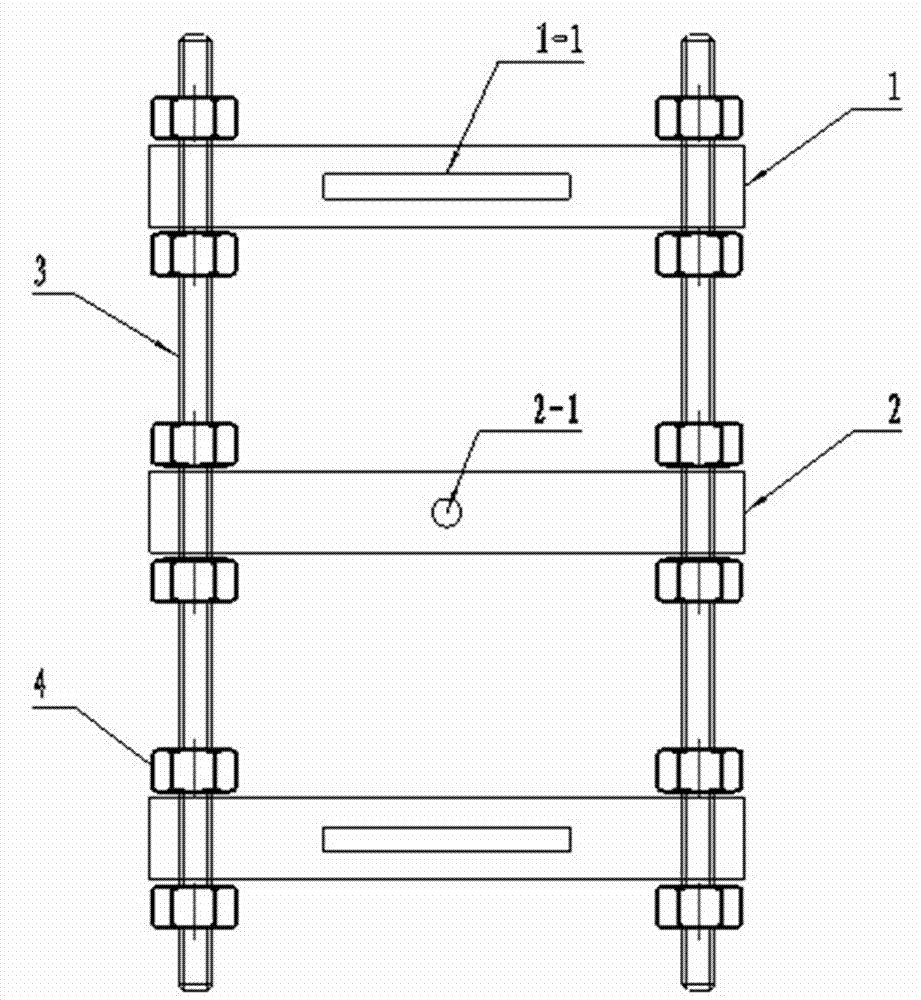

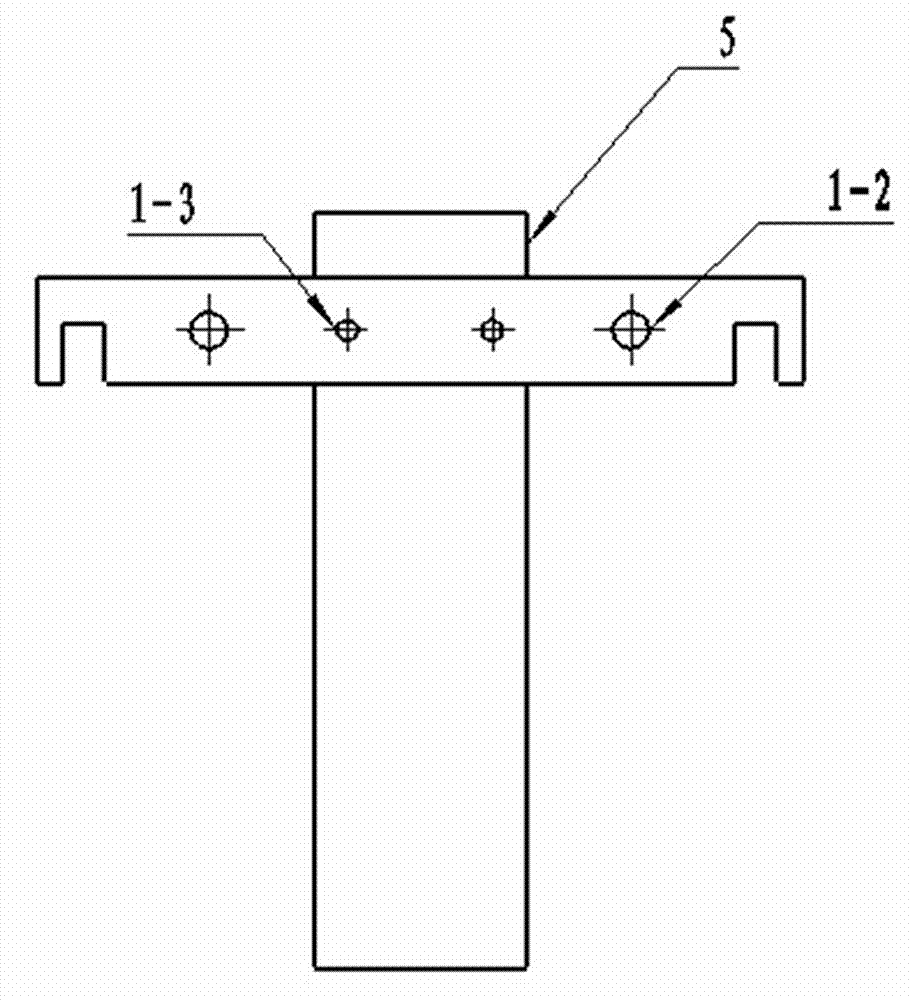

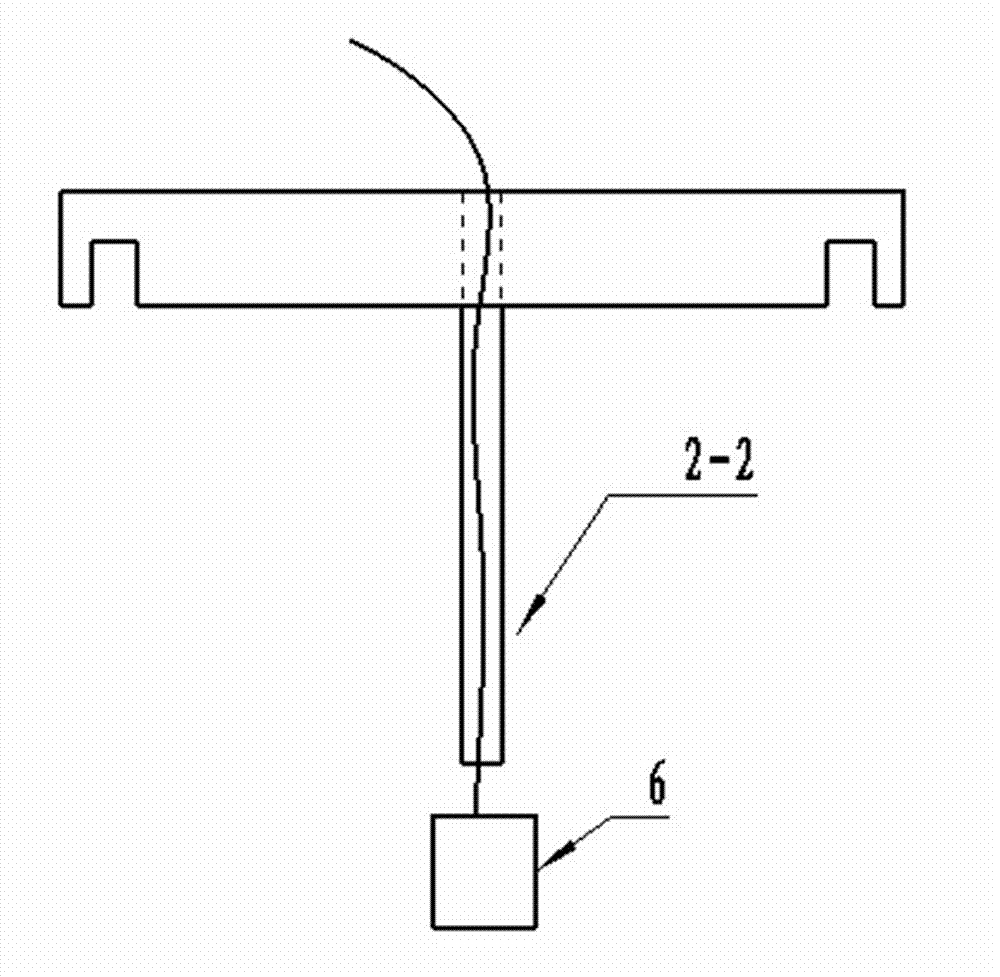

[0023] refer to figure 1 , figure 2 , image 3 , the present invention includes two horizontal rectangular support frames 1 for clamping the cathode 5 at both ends, a horizontal rectangular support frame 2 for fixing the anode 6 in the middle, two longitudinal long screw connectors 3 and several nuts 4 . The upper end of the rectangular support frame 1 is provided with a rectangular through hole 1-1 for inserting the cathode 5, and several horizontal circular through holes are provided on the side, of which 1-2 is used for installing long screws, and 1-3 is used for fixing the cathode . The rectangular support frame 2 is used to fix the anode workpiece 6, and the support is provided with a vertical circular through hole 2-1, and one end of a plastic cylinder 2-2 with a diameter of 4-8mm is assembled in the circular through hole 2-1 to realize interference fit. Two longer screw connectors 3 connect three rectangular support frames 2 in series, and nuts 4 are used to realiz...

Embodiment 2

[0026] The cathode 5 of this embodiment is a grid-type cathode, and the rest of the composition and connection methods are the same as those of the specific embodiment 1.

Embodiment 3

[0028] In this embodiment, nuts 4 are used to adjust the distance between the brackets, so that the electrode distance is 10 mm, and the rest of the composition and connection methods are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com