Light ultrathin wall steel structure house

A technology of ultra-thin wall and steel structure, which is applied in the direction of building structure, industrial building, construction, etc., to achieve the effect of improving the strength of the house, simplifying the assembly method, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

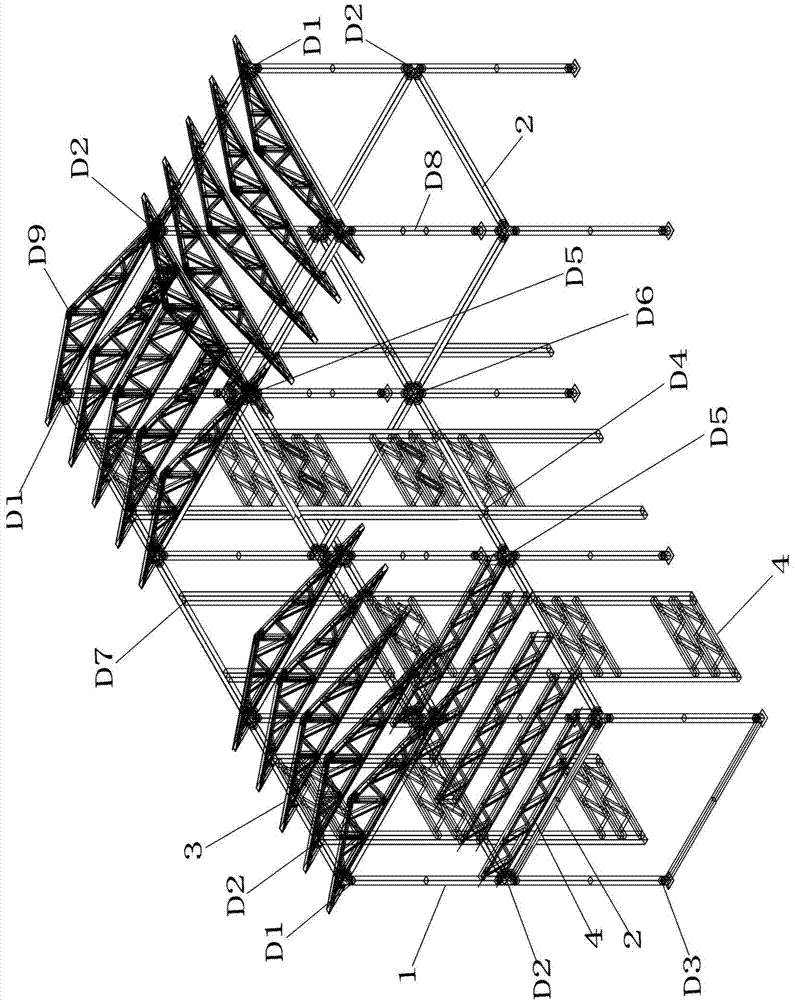

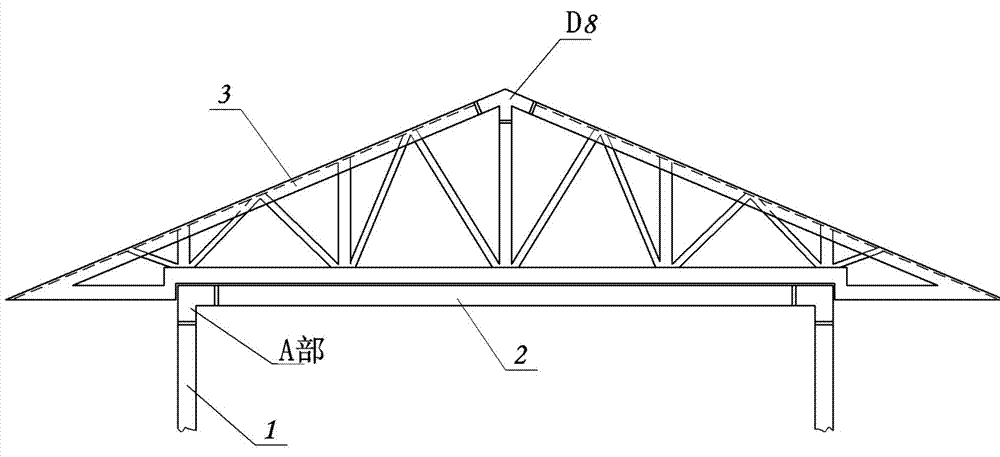

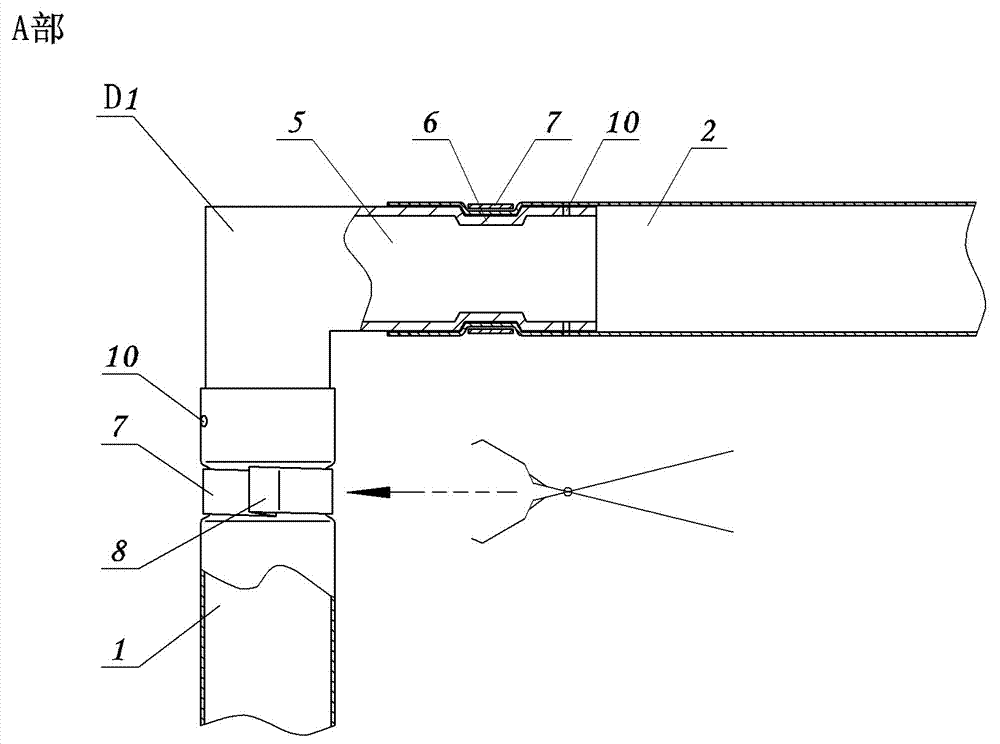

[0022] Embodiment 1: see figure 1 , a two-story light ultra-thin-wall steel structure house, including columns 1, beams 2, roof, 3, and roof, side walls and stairs. Among them, the column 1 and the beam 2 are respectively made of ultra-thin-walled square steel with a thickness of 0.6 mm. The columns 1 include top columns and bottom columns, and the beams include horizontal beams and longitudinal beams. A truss structure 4 may be used as a support between some adjacent columns. Columns on each floor are divided into corner columns and intermediate columns. The upper end of the corner column on the top floor is connected to the beam through node one, and the upper end of the middle column on the top floor is connected to the beam through node two. Figure 5 is the structure of node one, Figure 7 is the structure of node 2, in the figure, both node 1 and node 2 include three mutually perpendicular plugs with a thickness of 3mm, where Figure 7 Node two in also includes a fo...

Embodiment 2

[0030] Embodiment 2, accompanying drawing is not drawn, can refer to figure 1 , Figure 5 , Figure 7 and Figure 11 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that it is a single-layer light ultra-thin-wall steel structure house, and its structure includes columns, beams, roofs, and roofs and side walls. The column and the beam are ultra-thin-walled square steel with a thickness of 0.6mm, and the upper end of the column is connected to the beam through node 1 or node 2. Both node 1 and node 2 include three mutually perpendicular plugs with a thickness of 3mm. The fourth plug, the fourth plug is symmetrical to one of the other three plugs; the middle of each plug is provided with an annular groove; the upper end of the corner column uses plug one to connect with the longitudinal and transverse beams, and the middle column connects to the vertical and horizontal beams through node two The vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com