Fan filter unit and dust-free room air purification system

An air purification system, clean room technology, applied in air conditioning systems, machines/engines, chemical instruments and methods, etc., can solve problems such as failure to reach service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

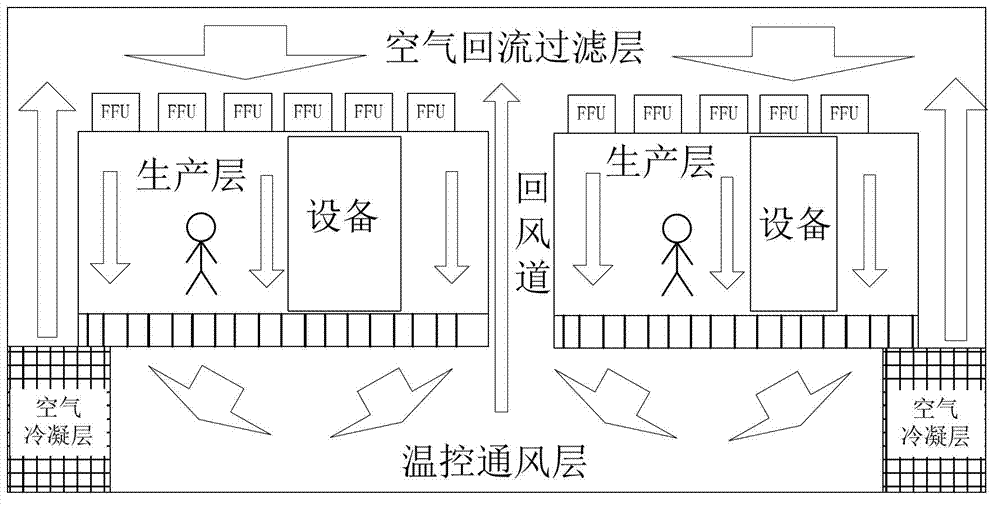

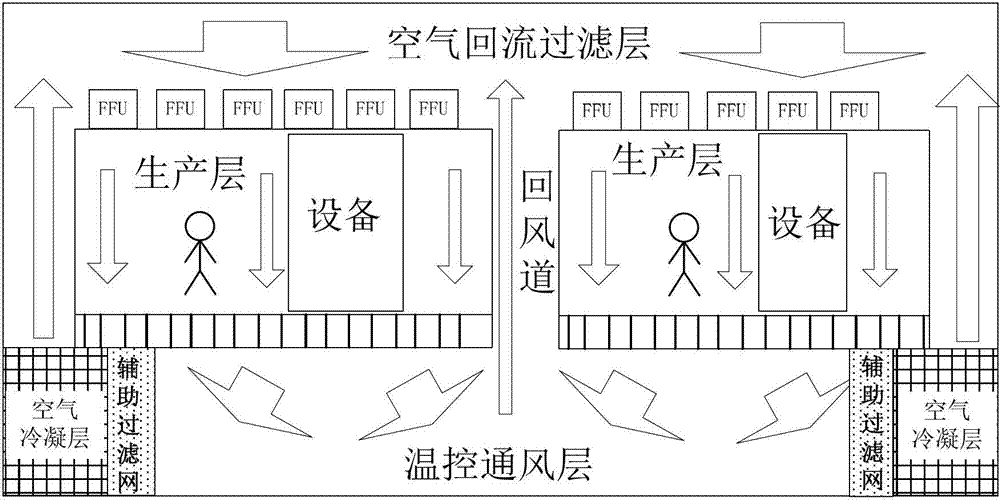

[0018] The invention discloses an air purification system for a clean room. The clean room air purification system includes a production floor and a fan filter unit connected to the production floor. The fan filter unit includes a fan and a filter screen coupled with the air inlet of the fan. The air inlet of the filter screen is also provided with an auxiliary filter. The minimum diameter of the dust that can be filtered by the auxiliary filter is larger than the minimum diameter of the dust that can be filtered by the filter.

[0019] The inventor found that when the dust particles enter the ventilation ducts, the large particles will be deposited first in the filter screen, and then the small particles will adhere to the surface of the large particles, so that the dust will accumulate in layers and will soon block the ducts and filters. net, shortening the service life of fan filter units and cleanroom air cleaning systems. The present invention adds an auxiliary filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com