Linear sealing pipeline connection structure

A connection structure, wire sealing technology, applied in the direction of adjustable connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of poor sealing effect, difficult to repair, low oil leakage rate, etc., to achieve good sealing, The effect of light weight and low chance of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

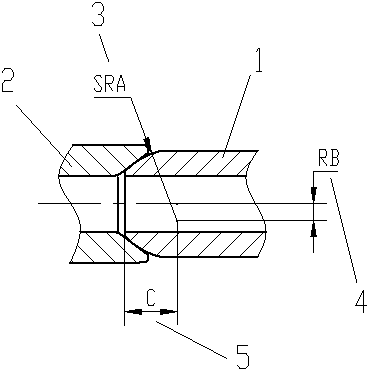

[0015] This embodiment provides a wire-sealed pipeline connection structure, which is characterized in that it includes an eccentric spherical surface 1, an inner cone surface 2, a size SRA3, a size RB4, and a size C5.

[0016] In the line sealing structure, the eccentric spherical surface 1 cooperates with the inner cone surface 2 to form a line sealing pipeline connection structure as a whole.

[0017] The basic structure of the eccentric spherical surface 1 is determined by the dimensions SRA3, RB4, and C5. The eccentric distance of the outer cone sphere is controlled by adjusting the dimension RB4; the axial position of the center of the eccentric ball is controlled by adjusting the dimension C5, and the radius of the eccentric ball is controlled by adjusting the dimension SRA3. Optimize and adjust the dimensions SRA3, RB4, and C5 to reduce the overall size of the eccentric spherical line sealing structure, and at the same time determine the best position of the sealing li...

Embodiment 2

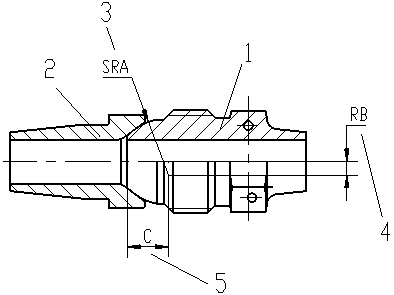

[0021] This embodiment provides a wire-sealed pipeline connection structure, which is characterized in that it includes an eccentric spherical surface 1, an inner cone surface 2, a size SRA3, a size RB4, and a size C5.

[0022] In the line sealing structure, the eccentric spherical surface 1 cooperates with the inner cone surface 2 to form a line sealing pipeline connection structure as a whole.

[0023] The basic structure of the eccentric spherical surface 1 is determined by the dimensions SRA3, RB4, and C5. The eccentric distance of the outer cone sphere is controlled by adjusting the dimension RB4; the axial position of the center of the eccentric ball is controlled by adjusting the dimension C5, and the radius of the eccentric ball is controlled by adjusting the dimension SRA3. Optimize and adjust the dimensions SRA3, RB4, and C5 to reduce the overall size of the eccentric spherical line sealing structure, and at the same time determine the best position of the sealing li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com