Section bar and method for obtaining product with clear color boundary by performing surface treatment on section bar

A technology for surface treatment and profiles, which is applied to devices for coating liquids on surfaces, anodizing, building components, etc. It can solve the problems of high processing costs, lowering the appearance of high-end smart TVs, grinding and scratching, etc. layered texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A large-size TV aluminum frame. According to customer requirements, the front of the product connected to the screen should be made black, and the outer side should be made of metallic sandblasting or brushed silver.

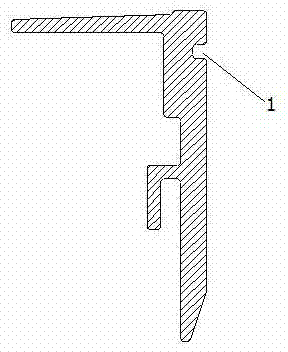

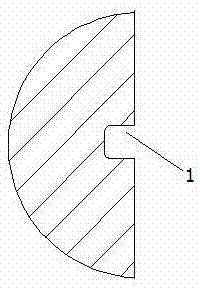

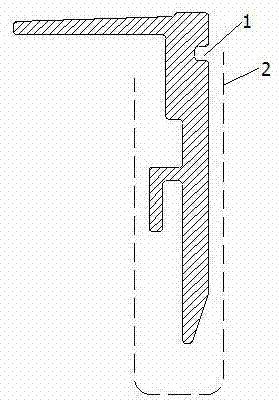

[0022] During the aluminum extrusion process of the aluminum frame, that is, the aluminum extrusion process tank 1, the position of the process tank is set at the boundary between the two colors of black and silver after surface treatment in the later stage of the plan. Partial cross-sectional schematic diagram of aluminum extruded aluminum frame, see figure 1 . Process tank 1 is a groove with a width of 0.8mm and a depth of 0.8mm, and the internal cross-sectional shape is a chamfered square (see figure 2 ), in other embodiments, it can also be arc, trapezoid, square, triangle and other shapes.

[0023] Use this aluminum profile for surface treatment, and the processing method for processing products with clear and beautiful color boundaries is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com