Method and device for fault diagnosis of diesel engine

A technology of fault diagnosis and diesel engine, applied in the direction of internal combustion engine testing, etc., can solve problems such as low accuracy of fault type diagnosis and untimely fault judgment, and achieve the effects of easy access, reduced fault incidence, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

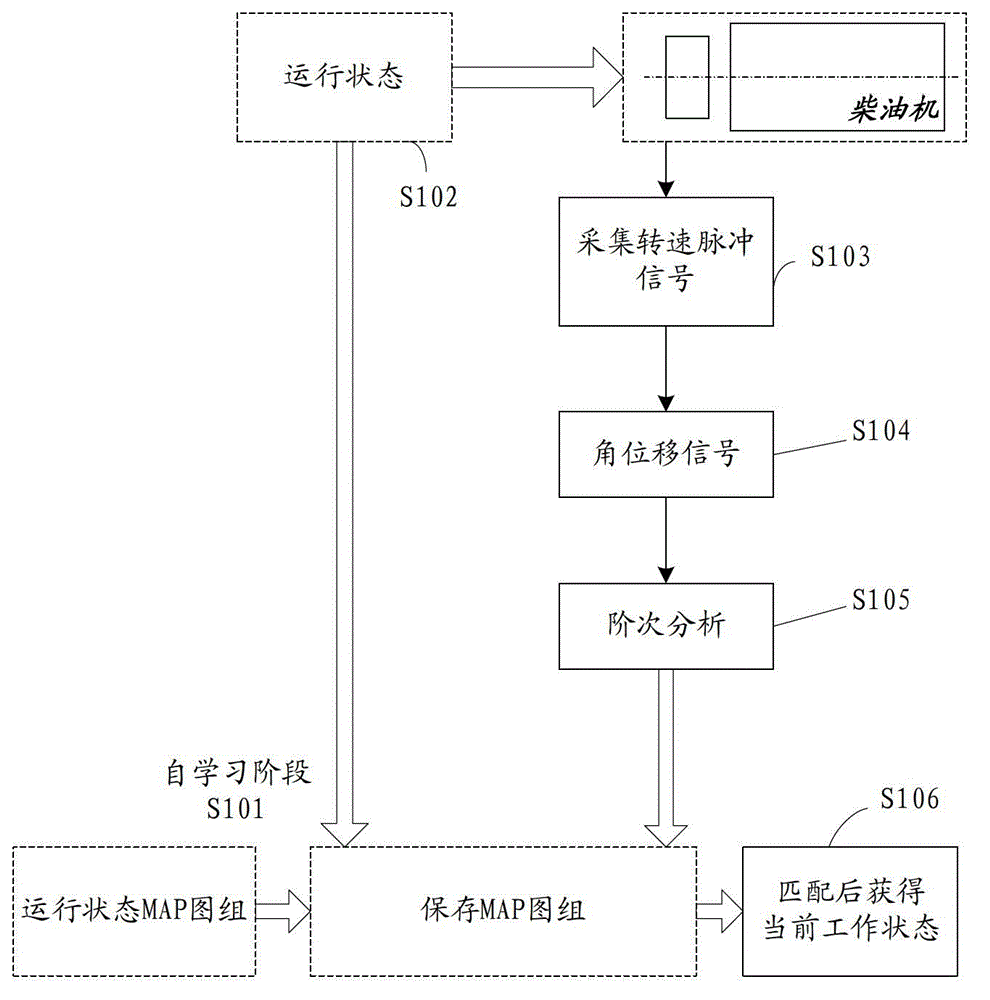

[0043] see figure 1 , which is a method flow chart of a diesel engine fault diagnosis method of the present invention, the method may include the following steps:

[0044] S101: When the diesel engine is running in various fault modes, the electronic control unit ECU monitors the running state of the diesel engine in advance and collects the speed pulse signal of the crankshaft gear plate of the diesel engine under the running state; obtains the angular displacement signal through the speed pulse signal; the diagonal displacement The order analysis of the signal is carried out to obtain the frequency domain characteristic quantity of the torsional vibration frequency domain amplitude signal corresponding to various failure modes under the monitored operating state, and the monitored operating state and the frequency domain characteristic quantity under the operating state are combined with each The corresponding relationship between the failure modes is saved.

[0045] Throug...

Embodiment 2

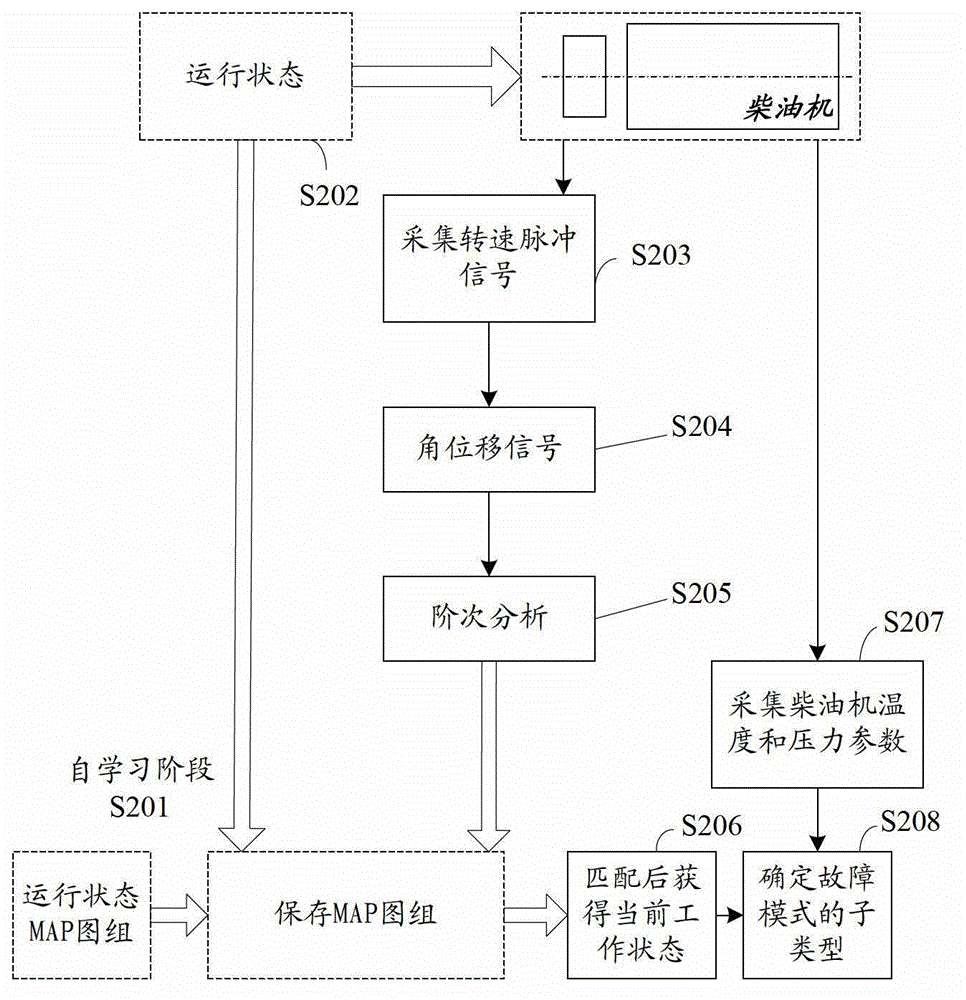

[0057] see figure 2 , which is another method flowchart of a diesel engine fault diagnosis method of the present invention, when the current working state of the obtained diesel engine is any fault mode, the method also includes the following steps:

[0058] For S201 to S206, please refer to S101 to S106 in Embodiment 1.

[0059] S207: The ECU collects parameters of the diesel engine's water temperature, engine oil pressure, engine oil temperature, intake pressure, and intake temperature.

[0060] S208: The ECU combines the collected parameters with the failure mode of the diesel engine to determine the subtype of the failure mode.

[0061] For example, if Figure 5 Shown is the change diagram of torsional vibration amplitude of the diesel engine transmission shaft when the injector wears 5%. by right Figure 5 According to the analysis of the torsional vibration frequency domain amplitude diagram of the shafting of the diesel engine, the power of the diesel engine increa...

Embodiment 3

[0064] see Image 6 , which is a system structure diagram of a diesel engine fault diagnosis system of the present invention, including a self-learning unit 601, a detection unit 602, a first acquisition unit 603, a conversion unit 604, an analysis unit 605 and a matching unit 606:

[0065] The self-learning unit 601 is used for when the diesel engine is running in various failure modes, the electronic control unit ECU pre-collects the speed pulse signals of the crankshaft gear plate of the diesel engine under various failure modes; through the speed pulse signals, the angular displacement signal is obtained ; The order analysis of the angular displacement signal is carried out to obtain the frequency domain characteristic quantity of the torsional vibration frequency domain amplitude signal corresponding to various failure modes, combined with the operating conditions of the diesel engine in various failure modes, and the correspondence of various failure modes The correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com