Conductive loop structure of switch device

A technology of conductive circuit and switchgear, applied in the direction of protection switch operation/release mechanism, protection switch terminal/connection, etc., can solve the problems that have not been seen in technical enlightenment, shorten the breaking time, improve the current limiting performance, and improve the breaking capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

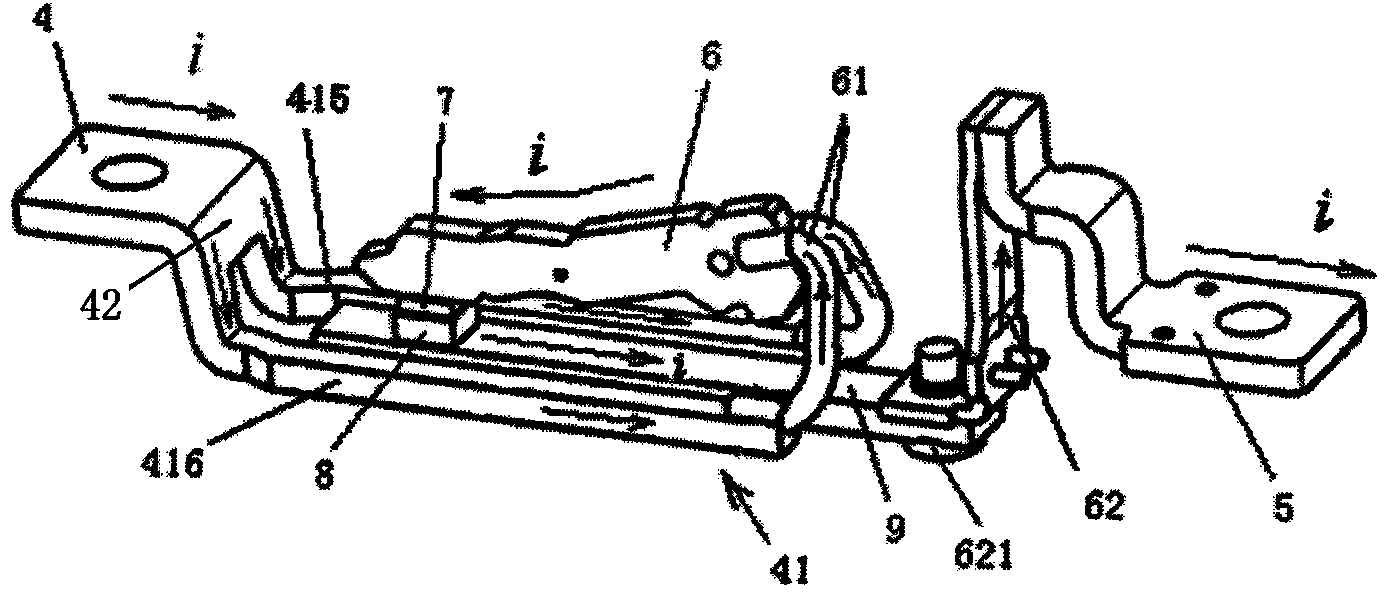

[0040] See figure 1 , figure 2 , Figure 10 as well as Figure 11 ,exist Figure 11 The operating mechanism 1, the arc extinguishing mechanism 2 and the tripping mechanism 3 of the switchgear are shown in the figure. Due to the structure, installation method (installed in the housing) and functions of the operating mechanism 1, the arc extinguishing mechanism 2 and the tripping mechanism 3, as well as each other The relationship between them belongs to the known technology, so the applicant will not describe it in detail, wherein, the tripping mechanism 3 can be either a thermal tripping mechanism or a magnetic tripping mechanism.

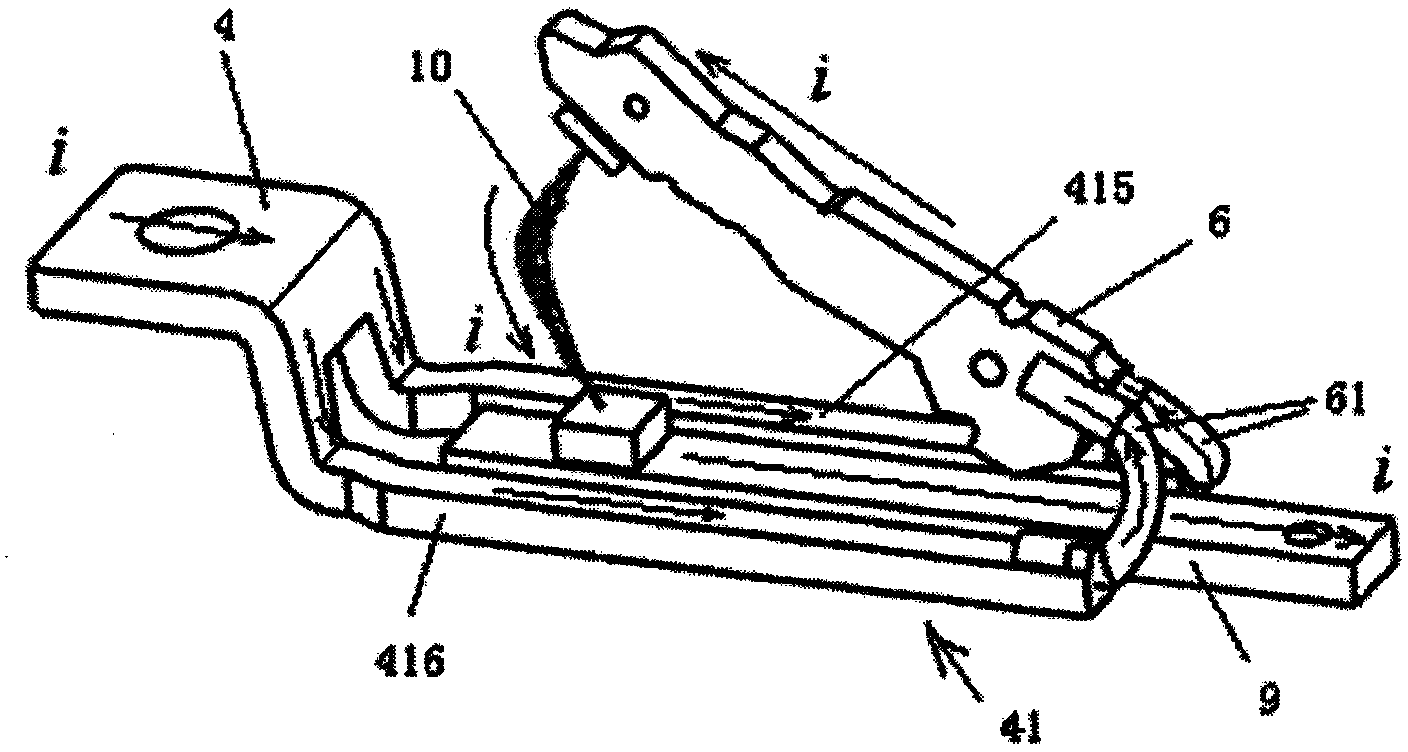

[0041] The conductive loop structure includes first and second connecting terminals 4 and 5, a movable guide rod 6, a movable contact 7 and a fixed contact 8, and the first connecting terminal 4 has a connecting guide rod extending toward one end of the second connecting terminal 5 41. Since the connecting guide rod 41 essentially act...

Embodiment 2

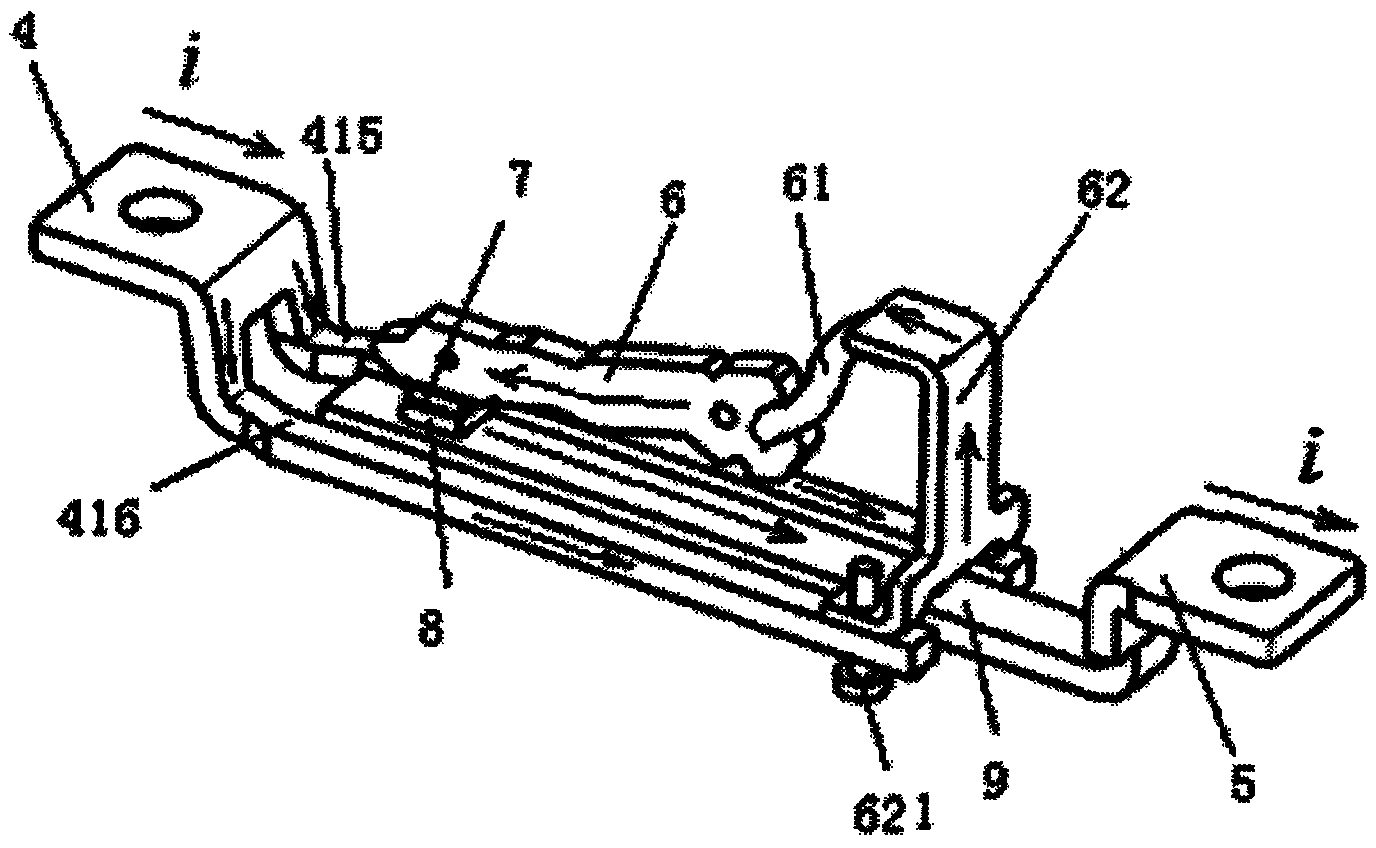

[0052] See image 3 , in this embodiment, the detection guide rod 62 of the conductive circuit is fixed to the end of the connecting guide rod 41 facing the second connection terminal 5 with a screw 621, more specifically to the first and second conductive arms 415, 416. One end facing the second connecting terminal 5 . One end of the aforementioned electrical connection device 61 , that is, a wire braided wire, is connected to the movable guide rod 6 , and the other end is connected to the detection guide rod 62 , so that the electrical connection device 61 appears as an indirect electrical connection with the connection guide rod 41 . And the second connection terminal 5 is directly fixedly connected with the fixed guide rod 9 , so that the end of the fixed guide rod 9 facing the second connection terminal 5 is directly electrically connected with the second connection terminal 5 . All the other are the same as the description to embodiment 1.

Embodiment 3

[0054] See Figure 4 , the figure shows that the electrical connection device 61 is a rigid connection conductor (because what embodiment 1 uses is a wire braided wire, so it can be called a flexible connection conductor), and the movable guide rod 6 is hinged on this connection through a pin shaft 63 On the rigid connection conductor, that is, the movable guide rod 6 is pivoted on the rigid connection conductor through the pin shaft 63, and elastic components (not shown) such as clip springs are used to give the rigid connection conductor and the connection guide Appropriate contact force is applied between the rods 41, and the rigid connecting conductor faces the connecting guide rod 41 after the conductive spacer 64 is added. Figure 4 One end of the second connection terminal 5 not shown in the figure is fixed, more specifically, it is fixedly connected with the end of the first and second conductive arms 415 , 416 facing the second connection terminal 5 . All the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com