Method for detecting insert objects in injection-moulded part

一种插入物、零件的技术,应用在涂层等方向,能够解决复杂评价系统等问题,达到省去启动、容易评估、节省高费用的分析的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

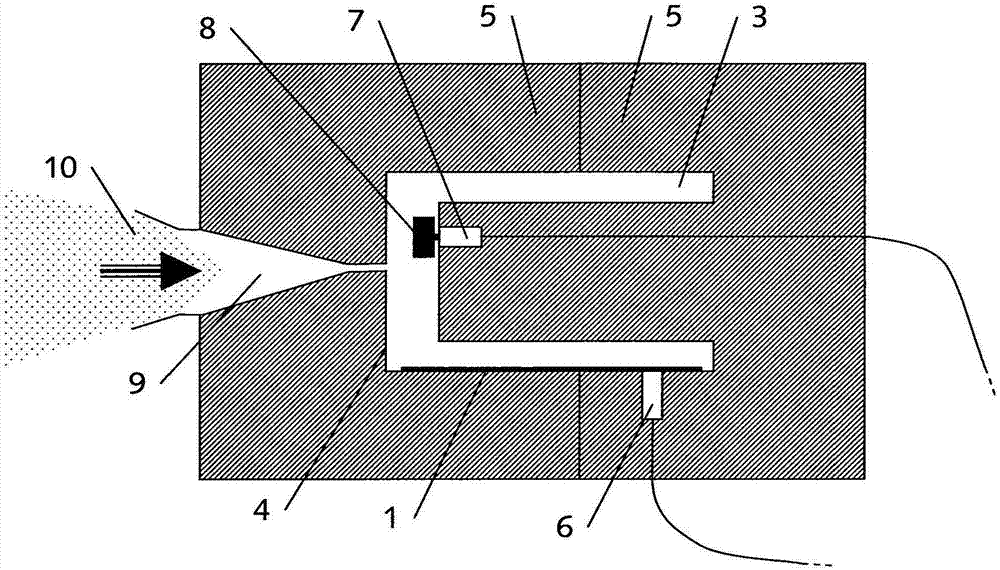

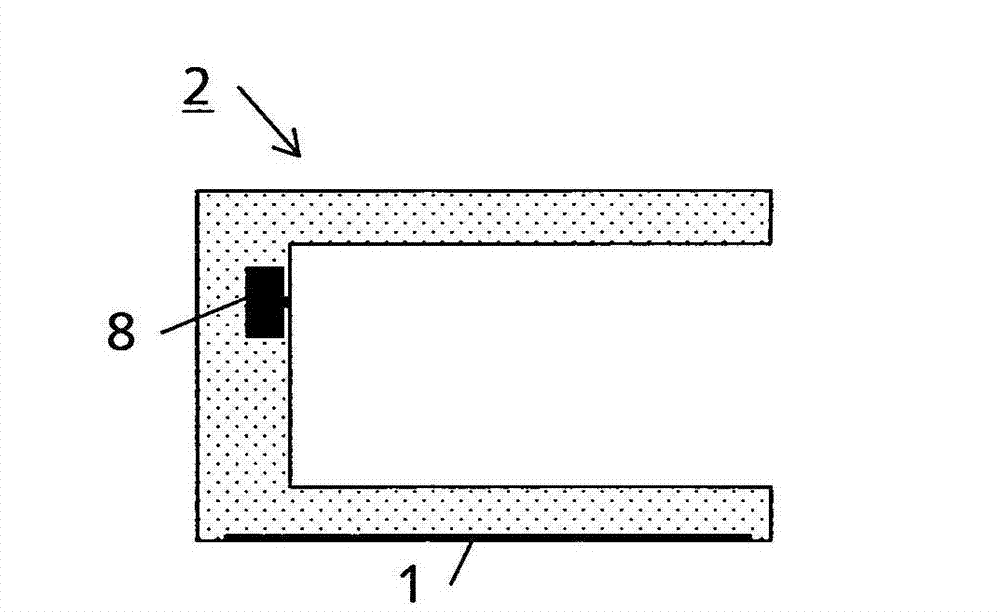

[0019] figure 1 A cross-sectional view of a mold 5 of an injection molding apparatus is shown. The mold 5 consists of two halves which together define a cavity 3 surrounded by mold walls 4 . In injection molding, an injection molded part 2 is formed in a cavity 3, such as figure 2 shown. For this purpose, a melt 10 of liquid plastic is injected into the cavity 3 through the spout 9 . After the melt 10 has solidified, the two mold halves 5 are opened and the finished injection molded part 2 is demoulded. An injection molding cycle ends here.

[0020] Inserts 1 , 8 can be inserted into cavity 3 before the two mold halves 5 are joined again to start a new cycle. When the melt 10 is injected, these inserts 1 are joined with the melt 10 to form an injection molded part 2 .

[0021] The method according to the invention for detecting inserts 1 , 8 in injection molded parts 2 will be described below.

[0022] According to the invention, at least one sensor 6 , 7 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com