Manufacturing method of pulley shaft for belt continuously variable transmission

A technology of continuously variable transmission and manufacturing method, applied in the direction of elements with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problem that materials cannot be spread all over the model, the hardness of the workpiece is not sufficiently reduced, and the fluidity of the model material is reduced, etc. problems, to achieve the effect of ensuring fluidity, suppressing temperature drop, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

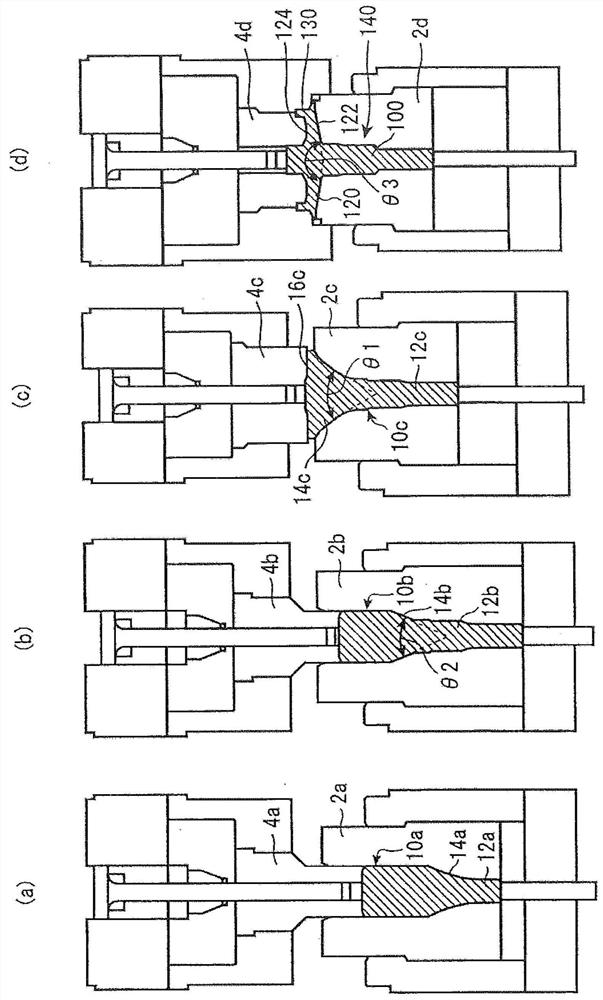

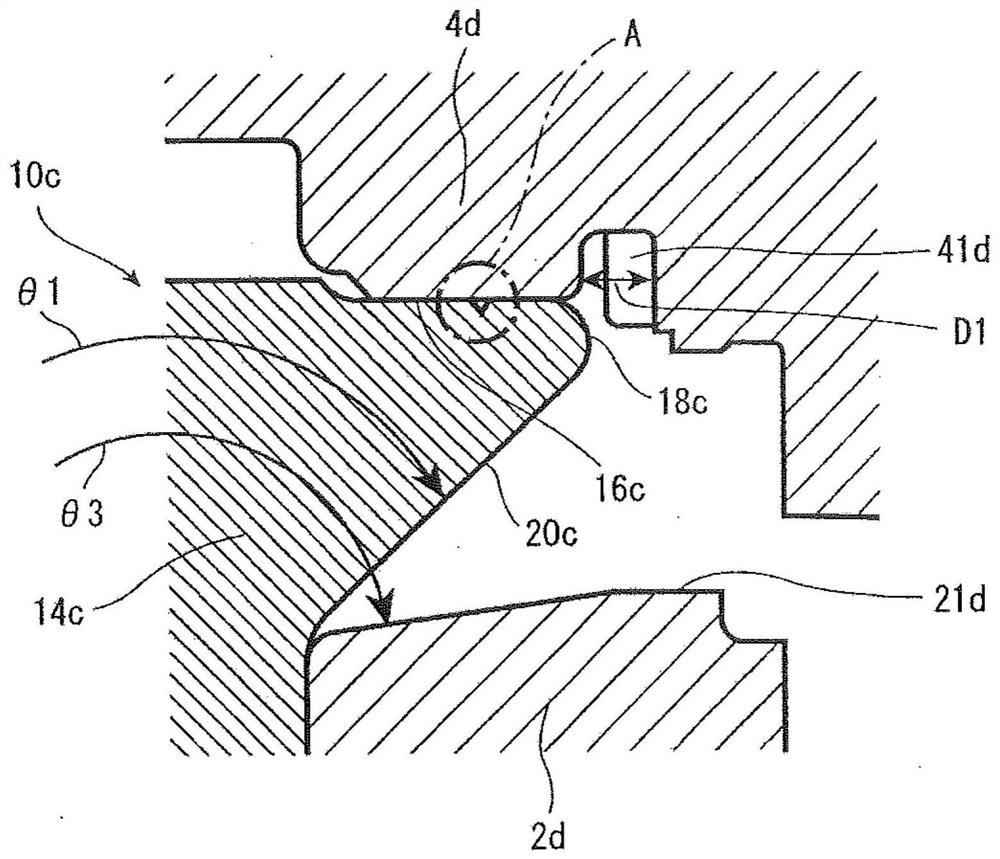

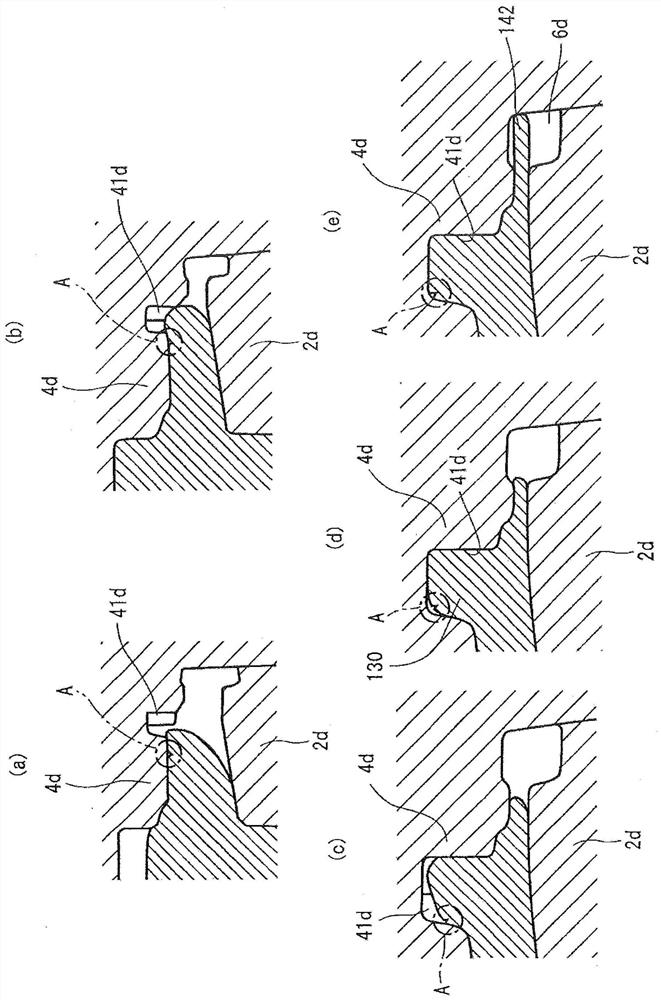

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] In addition, the embodiments shown below are merely examples, and various modifications and technical applications not explicitly described in the following embodiments are not excluded.

[0037] In addition, the forging device used in this embodiment is the same as a conventionally well-known general forging device except for the model shape of the model, and therefore description of each part of the device will be omitted.

[0038] Furthermore, in figure 1 In , in order to clarify the shape of the workpiece formed in each process, the shading of the cross-sectional portion of the forging device is omitted.

[0039] First, as a pre-process of implementing the first process, an unillustrated cylindrical workpiece made of high Si steel is heated to 1120° C. to 1160° C. (subthermal forging).

[0040] After that, the heated cylindrical workpiece is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com